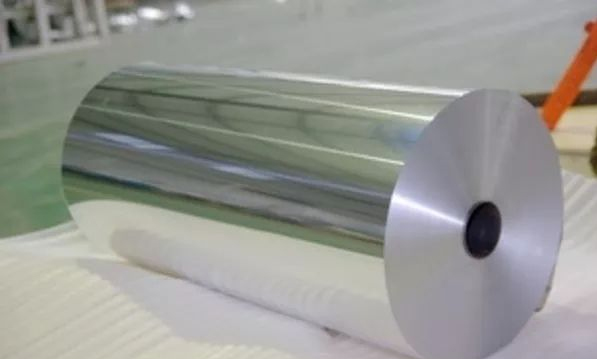

Aluminum foil is the sole metal foil used in flexible packaging. Aluminum foil uses on packaging has a long time. Aluminum foil is used as a packaging material, which cannot be completely replaced. Aluminum foil is made of electrolytic aluminum with a purity of 99.0%~99.7%, which is produced through repeated rolling. It is rich in resources and has a considerable advantage in performance and price. Thus, aluminum foil has fully demonstrated its broad application prospects in many fields. Today, this article will introduce you to uses for aluminum foil.

Aluminum foil uses in household

Household aluminum foils are widely used in cooking, freezing, fresh-keeping, baking, and other industries. In the refrigerator or freezer, wrap aluminum foil directly on the food to keep it from deforming, limit water loss in fish, vegetables, fruits, and dishes, and avoid flavor leakage or mixing. Because aluminum foil has strong and uniform thermal conductivity and heating effect, it may be heated directly on the original packaging in ovens, steamers, and so on. Common specifications of aluminum foil are 0.007-0.05mm. These are household uses for aluminum foil.

Aluminum foil uses in medicine

Aluminum foil is useful for packaging medications since it is non-toxic, resistant to corrosion, impermeable, heat-resistant, moisture-proof, light-blocking, etc. It is mostly used for the blister packaging of medicinal capsules, tablets, etc., as well as the bag packing of powder grains and water. Especially, PTP aluminum foil is moisture-proof, easy to carry, safe, and hygienic, and is widely used in the international pharmaceutical industry. Pharmaceutical aluminum foil producing factories have rather strict criteria for the production environment. The requirements, for instance, do not go below 100,000-level purification workshops. There are two kinds of alloy states in common medicinal aluminum foils on the market. The first one is O. After it is cold stamping, it is used for high-end pharmaceutical packaging. The second is H18. After coating, it is used for PTP pharmaceutical aluminum foil. The common thickness is 0.006-0.08mm. These are medical uses for aluminum foil.

Aluminum foil uses in battery

Battery aluminum foil is one of the base materials for new energy vehicle lithium batteries. In general, rolled aluminum foil is used as the positive electrode collector in the lithium-ion battery business. Common specifications of battery aluminum foil are 0.009-0.1mm. These are batteries uses for aluminum foil.

Aluminum foil uses in Air conditioners

Air conditioner aluminum foil is a specialty material used to make heat exchanger fins for air conditioners. Initially, air conditioner aluminum foil was plain. To improve the surface properties of the plain foil, it is coated with an anti-corrosion inorganic coating and a hydrophilic organic coating before forming to form a hydrophilic foil. It is frequently used in refrigerators, air conditioners for cars, domestic and commercial use, and other refrigeration equipment. Another type of hydrophobic foil is also available, giving the fins’ surface a hydrophobic quality and preventing condensation from adhering. It is mostly used in dryers to improve heating efficiency. The air conditioner’s aluminum foil thickness is 0.07mm~0.2mm. With the development of technology, air-conditioning aluminum foil tends to be further thinned. These are air conditioners used for aluminum foil.

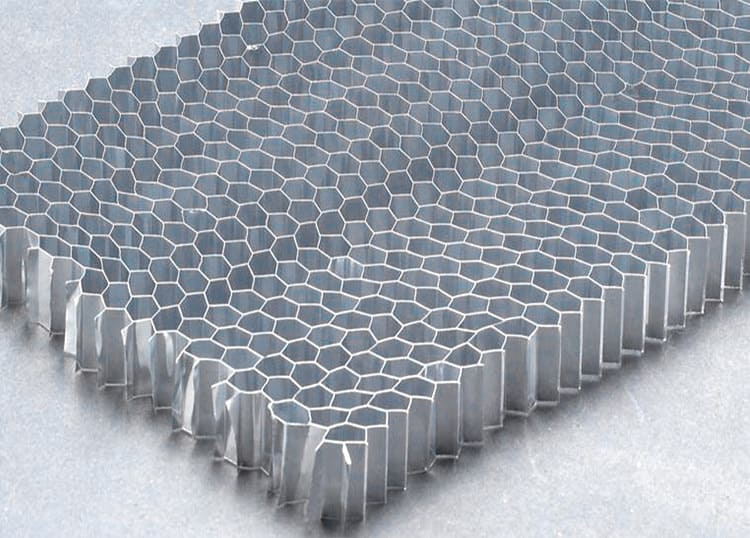

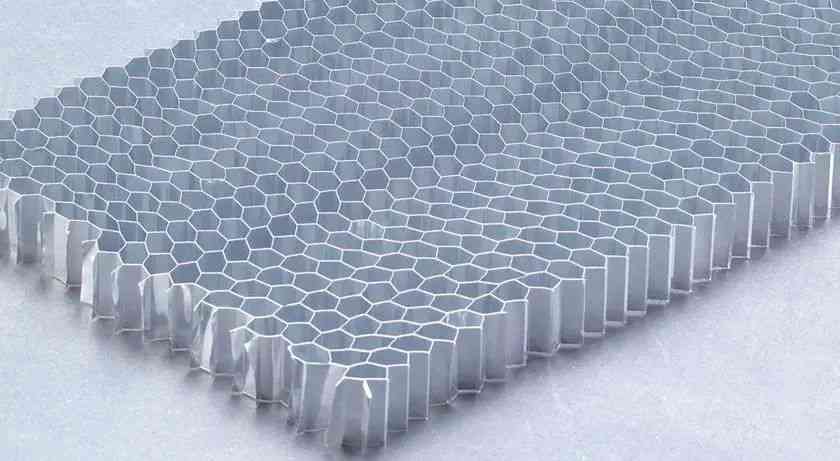

Aluminum foil uses – honeycomb aluminum foil

Honeycomb aluminum foil has the advantages of being lightweight, high strength, and high rigidity, and is widely used in the decoration of high-rise building exterior walls. The interlayer of honeycomb aluminum foil contains a lot of air, which can be sound-proof, heat-insulating, waterproof, moisture-proof, heat-preserving, and has no harmful gas release. The common thickness of honeycomb aluminum foil is 0.035-0.08mm.

Aluminum foil uses -electronic aluminum foil

After the aluminum material is processed into a foil, the electronic aluminum foil is subjected to surface corrosion treatment and re-oxidation treatment and then winding processing to make a capacitor. The aluminum foil before corrosion is called a light foil. The aluminum foil after corrosion is called the corroded foil, and the aluminum foil after re-oxidation treatment is called a foil. Aluminum foil used in electronics usually refers to light foil, the main component used to make aluminum electrolytic capacitors. The electrode aluminum foil consists of corrosion foil and produced foil. The types of electronic aluminum foil include negative electrode foil, high voltage anode foil, and low voltage anode foil. Among them, the high and low-voltage anode foil (forming foil) needs to use more than 99.99% high-purity aluminum. The thickness of the high-voltage anode foil is 0.0065-0.11mm, and the thickness of the low-voltage anode foil is 0.04-0.1mm.

Aluminum foil uses in flexible packaging

Flexible packaging aluminum foil is a bag-type container made of flexible composite packaging materials. According to different uses of flexible packaging, different processes such as dry lamination, hot-melt lamination, and extrusion lamination are used. Flexible packaging not only has the functions of moisture-proof and fresh-keeping but also can print various patterns and characters, so it is an ideal material for modern commercial packaging. Common specifications of flexible packaging aluminum foil are 0.0058-0.03mm. These are packaging uses for aluminum foil.

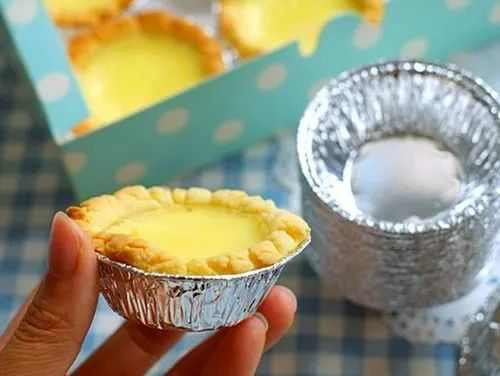

Aluminum foil uses – container aluminum foil

Food utensils such as quick food restaurants, takeaway fast-dating businesses, high-end hotels, airline tableware, and family kitchens use container aluminum foil. It offers features including a lovely aesthetic, ease of use, safety, and sanitation, as well as no odor pollution. Common specifications of container aluminum foil are 0.01-0.2mm.

Aluminum foil uses in cigarettes

Aluminum foil for cigarettes is mostly mixed with paper and used as the inner lining paper of cigarette boxes. The aluminum foil paper used as the inner lining paper of cigarettes mostly consists of calendered aluminum foil paper and aluminized paper. The surface of the tobacco foil is smooth and void of traces, the plate shape is flat, there are few pinholes, the price is reasonable, and the chemical qualities are steady. The aluminum foil within the cigarette box has two purposes: one is to keep the aroma, preventing the smell of cigarettes from spreading and corroding other goods, and the other is to prevent mildew. Aluminum foil can block moisture and effectively prevent moisture, thereby preventing cigarettes from mildewing in a humid environment. The thickness is 0.0063-0.0065mm. These are aluminum foil uses for cigarettes.

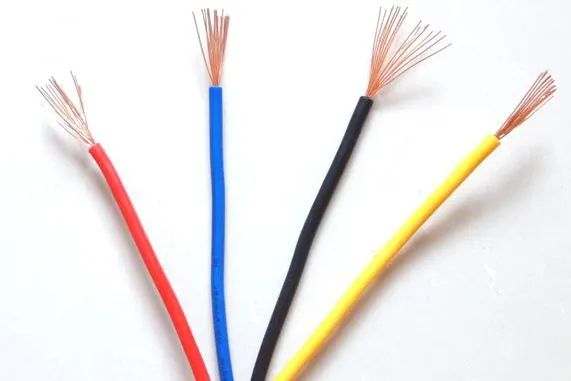

Aluminum uses in cable

Cable aluminum foil is an aluminum-plastic composite foil made of aluminum-plastic composite foil coated with plastic film on one or both sides by utilizing the airtightness and shielding properties of aluminum foil. Cable foil has to have minimal oil on the surface, no holes, good mechanical qualities, and low overall quality, but it has to be exceptionally long. The commonly used thickness of cable aluminum foil is 0.007-0.2mm. These are cables used for aluminum.

Aluminum foil uses in decorative

Decorative aluminum foil is a decorative material applied in the form of aluminum-plastic composite, which takes advantage of the characteristics of good coloring and high light and heat reflectivity of aluminum foil. It is mainly used for construction, furniture decoration, and some gift box packaging. It is generally used as a decorative material for the inner walls of buildings and indoor furniture and is also widely used in the facade and interior decoration of commercial institutions. Decorative aluminum foil has the advantages of heat insulation, moisture resistance, sound insulation, fire prevention, and easy cleaning. The thickness of the decorative aluminum foil is usually 0.01-0.2mm. These are decorative uses for aluminum foil.