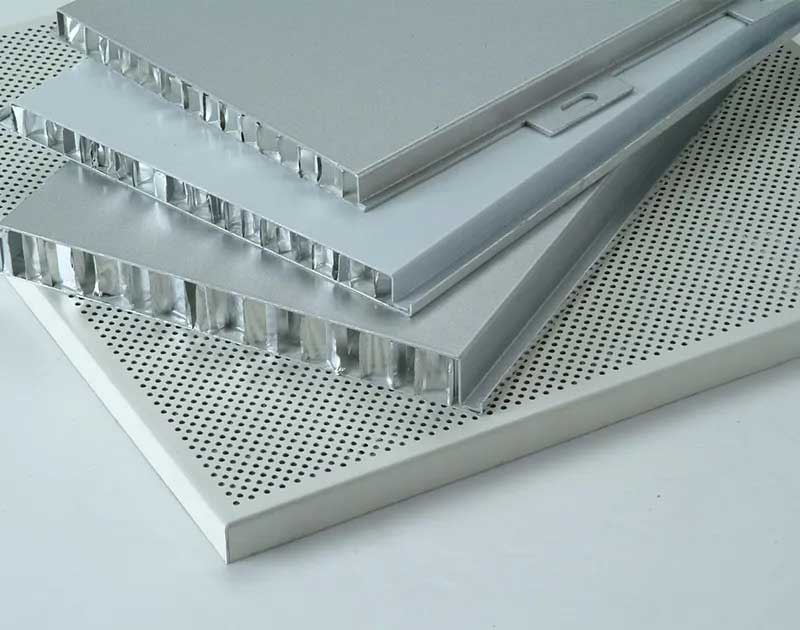

Various industries use aluminum alloys due to their high strength, lightweight and corrosion resistance. Among the most commonly used aluminum alloys are 2024 and 6061, which are widely used in the aerospace, automotive, and structural engineering industries. Today, we will compare and contrast the properties, applications, machining, and processing characteristics, and cost and availability of 2024 aluminum plate and 6061 aluminum alloy plate.

Properties of 2024 Aluminum Plate

2024 aluminum plate is a high-strength alloy that is commonly used in airplane structures due to its wonderful strength-to-weight ratio. The composition of 2024 aluminum plate is mostly aluminum with copper, manganese, magnesium, and zinc added to improve its strength and durability. The tensile strength of 2024 aluminum plate can range from 68,000 to 78,000 psi, making it one of the strongest aluminum alloys available. It has been become the first choice for outdoor and marine applications due to its corrosion resistance. Additionally, 2024 aluminum plate can be heat-treated to improve its strength and hardness.

Properties of 6061 Aluminum Alloy Plate

6061 aluminum alloy plate is another popular aluminum alloy that is commonly used in structural applications such as bridge construction, buildings, and heavy-duty machinery. The composition of 6061 aluminum plate is mostly aluminum with magnesium and silicon added to improve its strength and workability. The tensile strength of 6061 aluminum alloy plate can range from 40,000 to 45,000 psi, making it less strong than 2024 aluminum plate. However, 6061 aluminum plate has been become the first choice for outdoor and marine applications due to its corrosion resistance. It is also easy to be machined and cut into different kinds of shapes and sizes.

Comparison of Properties

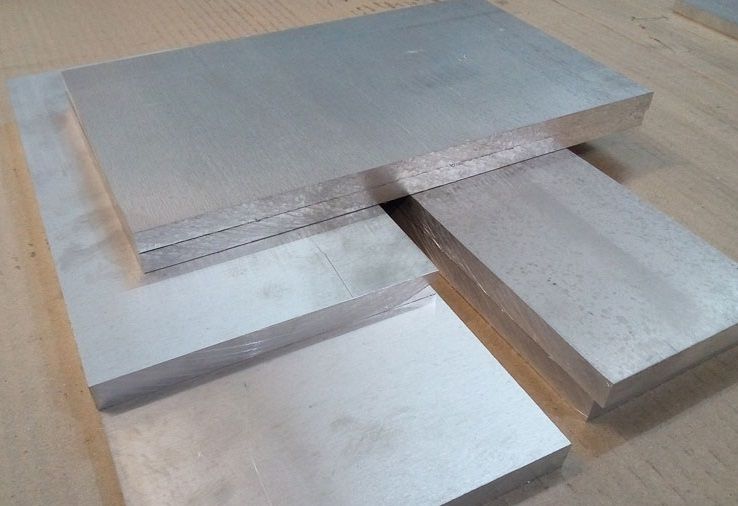

When comparing the properties of 2024 aluminum plate and 6061 aluminum alloy plate, the main differences are in strength and workability. 2024 aluminum plate is much stronger than 6061 aluminum alloy plate, with a tensile strength that can be up to 80% higher. This makes 2024 aluminum plate an ideal choice for applications where strength and durability are critical, such as aircraft structures. On the other hand, 6061 aluminum alloy plate is highly feasible and can be easily processed and formed into various shapes and sizes. This makes it an ideal choice for applications where versatility and flexibility are important, such as structural engineering.

Applications

2024 aluminum plate is commonly used in airplane and aerospace applications due to its high strength-to-weight ratio, excellent fatigue resistance, and good machinability. It is also used in other applications such as structural engineering, military vehicles, and sports equipment. 6061 aluminum alloy plate is commonly used in structural applications such as bridge construction, buildings, and heavy-duty machinery. It is also used in marine and outdoor applications due to its excellent corrosion resistance.

Machining and Processing

2024 aluminum plate and 6061 aluminum plate have different machining and processing characteristics. 2024 aluminum plate is less workable than 6061 aluminum alloy plate, and it can be difficult to form and shape without cracking. However, 2024 aluminum plate can be easily machined using conventional techniques such as milling, turning, and drilling. 6061 aluminum alloy plate, on the other hand, is highly workable and can be easily formed and shaped into various shapes and sizes using conventional techniques such as bending, punching, and stamping. It can also be easily machined using conventional techniques.

Welding and Joining

Both 2024 aluminum plate and 6061 aluminum alloy plate can be welded and joined using conventional welding techniques such as TIG and MIG welding. However, care must be taken during welding to avoid cracking due to the different properties of the two alloys. It is also important to use the correct filler metal for welding, as the wrong choice of filler metal can lead to cracking and other defects.

Cost and Availability

The cost of 2024 aluminum plate is generally higher than that of 6061 aluminum alloy plate, due to its higher strength and durability. Additionally, 2024 aluminum plate is less commonly available than 6061 aluminum alloy plate, which can make it more difficult to obtain in certain sizes and quantities.

Conclusion

In conclusion, the choice between 2024 aluminum plate and 6061 aluminum alloy plate depends on the specific application and requirements. If strength and durability are critical, 2024 aluminum plate is the best choice. However, if workability and versatility are important, 6061 aluminum alloy plate is the better choice. Both alloys have good corrosion resistance and can be easily welded and joined using conventional welding techniques. Additionally, the cost and availability of the two alloys should also be considered when making a decision.

In future research, it would be interesting to investigate the use of hybrid alloys that combine the properties of 2024 aluminum plate and 6061 aluminum alloy plate to create a new alloy with even better properties. This could lead to the development of new and improved aluminum alloys that are even more suitable for various applications in different industries.

In summary, 2024 aluminum plate and 6061 aluminum alloy plate are both widely used aluminum alloys with different properties and applications. By understanding the properties, applications, machining and processing characteristics, and cost and availability of each alloy, it is possible to make an informed decision on which alloy is best suited for a specific application.

Related Products

Related Articles