CHAL is a professional aluminum finned tube supplier, we often encounter some questions from customers about finned tubes. This article will answer the three most important questions and hopefully help you when shopping for finned tubes.

What are the characteristics of finned tubes?

- Heat transfer characteristics

The heat transfer characteristics of finned tubes are related to the contact thermal resistance between the fin and the tube, and the key to the contact thermal resistance is the contact pressure between the two. The heat transfer characteristics of the welded sheet type and the sleeve type are better, followed by the bimetal rolled sheet type, and the insert type and the wound sheet type are relatively poor.

After the KLM type finned tube is rolled again, the contact area is increased by about 50%, and it will not be disturbed by the tolerance of the outer diameter of the tube. Thermal characteristics are high.

The slotted finned tube can enhance the overall heat transfer coefficient by about 20% because of the improved airflow disturbance.

- Atmospheric corrosion resistance

The finned tube can resist atmospheric corrosion. Different types of finned tubes have different resistance to atmospheric corrosion because of the different scopes of protection. Among them, the finned tube processed by hot-dip galvanizing on the surface has the strongest atmospheric corrosion resistance.

In chemical plants or coastal areas with some corrosive gases in the atmosphere, special attention should be paid to the selection of raw materials and types of finned tubes, and aluminium finned tubes are prone to corrosion.

- Temperature resistance

Different types of aluminium finned tubes or steel finned tubes have different temperature resistance properties. The fin tension of the wound finned tube decreases rapidly as the temperature increases, so the contact thermal resistance increases rapidly. The bimetal rolled sheet type can be relatively stable in a relatively large temperature range.

Where can finned tubes be used?

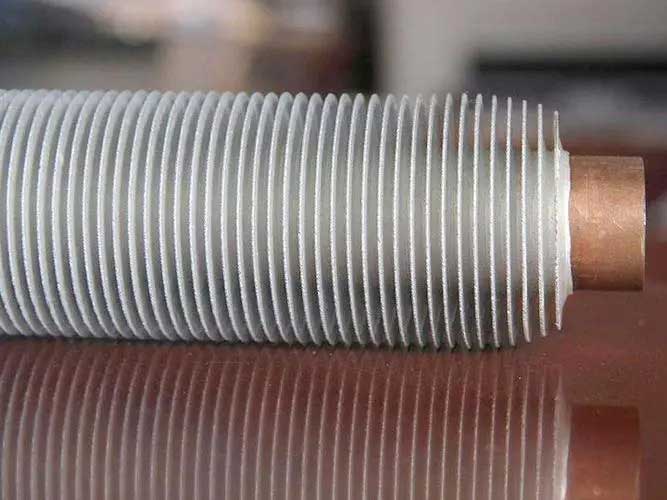

Aluminum finned tube is a new type of wear-resistant and efficient heat exchange material. It is an energy-efficient heat exchange element. It uses high-frequency welding production technology and a high-frequency power supply as a heat source to heat aluminium strips and aluminium tubes at the same time, and then weld them together.

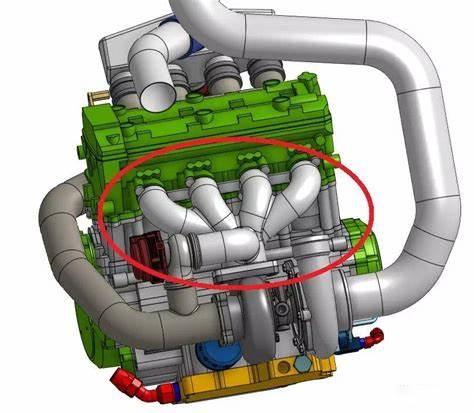

The finned tube it is a practical purpose to better improve the heat exchange efficiency. Therefore, fins are installed on the surface layer of the heat exchange tube, and then the total surface area of the heat exchange tube is increased, or the internal surface area is increased. The finned tube can be regarded as a heat exchange component, and it is one of the most widely used and widely used.

The finned tube is the most important part of the finned tube radiator. Among all types of finned tube radiators, the best heat transfer radiator is the spiral fin radiator.

What material can the finned tube be made of?

The material of the heat exchanger finned tube should be selected according to the application field and actual working conditions of the heat exchanger. The more commonly used materials at this stage are aluminum, aluminum alloy, copper, brass, nickel, titanium, steel, Inconel, etc. Among them, aluminum and aluminium alloys are used more.

The material selection principle of a fin-and-tube heat exchanger is to have good brazing and formability, high tensile strength, good corrosion resistance, and thermal conductivity.

Aluminum and aluminum alloys not only meet these requirements but also have the characteristics of increased ductility and tensile strength with decreasing temperature, so aluminum finned tubes are used worldwide in compact heat exchangers, especially low-temperature compacts type heat exchangers.