Aluminum floor sheets have become a popular choice for truck cargo boxes due to their lightweight, durability, and corrosion resistance. Whether you’re in the logistics business or manufacturing trucks, understanding the key points about aluminum floor sheets is crucial for choosing the right material. In this article, we’ll explore what aluminum floor sheets for truck cargo boxes are, why they’re used, and how to maintain them.

1. What is an Aluminum Floor Sheet for Truck Cargo Boxes?

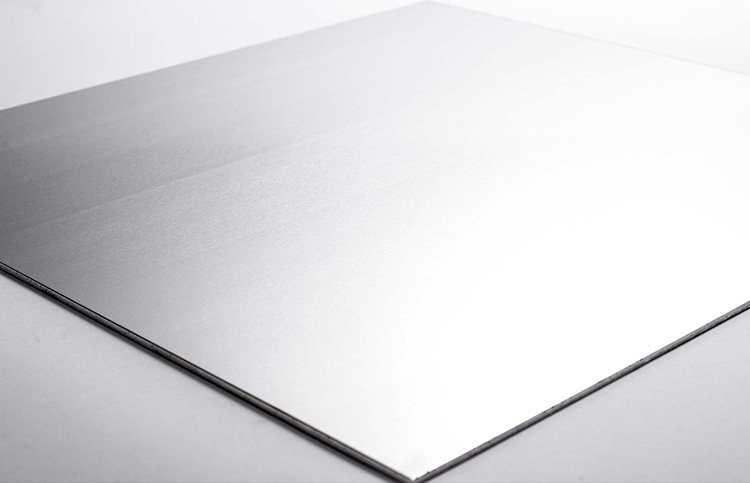

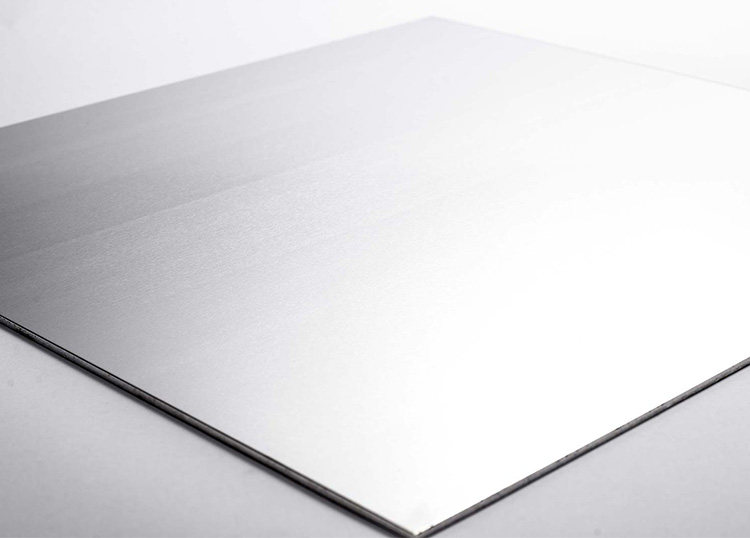

An aluminum floor sheet is a specialized metal panel designed to replace the original steel floor in truck cargo boxes. These sheets are typically made from high-strength aluminum alloys, providing a strong and durable surface capable of withstanding heavy loads and harsh working conditions.

Commonly Used Aluminum Sheet Alloys:

Aluminum sheets used in truck cargo boxes are often made from specific alloys like 3003, 5052, and 6061.

- 3003 Aluminum Sheet: Known for its good corrosion resistance, moderate strength, and excellent workability, this alloy is often chosen for light-duty trucks.

- 5052 Aluminum Sheet: This alloy offers greater strength and better corrosion resistance, making it suitable for more demanding environments like coastal or industrial areas.

- 6061 Aluminum Sheet: Often used in heavy-duty trucks, this alloy provides the highest strength and excellent machinability but is slightly more expensive.

Manufacturing Process

Aluminum floor sheets are typically manufactured using a combination of rolling and extrusion processes. The alloy is first rolled into sheets of the desired thickness, then further shaped and formed using extrusion techniques to create the desired contours and dimensions.

Finishing or Pattern Types

To improve grip and safety, aluminum floor sheets often come with different surface patterns such as diamond tread or checkered plates. These patterns also enhance the aesthetics and add extra durability. In some cases, anodizing is applied to improve corrosion resistance further. Some hot choices are:

- Smooth Finish: This finish provides a clean and polished appearance, making it suitable for applications where aesthetics are important.

- Aluminum Diamond Plate: A popular choice for truck cargo boxes, diamond plate patterns offer excellent traction and slip resistance, even in wet or icy conditions.

- Aluminum Checker Plate: Similar to diamond plate, checker plate patterns provide good traction and durability, but with a slightly different pattern.

Applicable Truck Types

Aluminum floor sheets are used in a wide variety of trucks, and the specific alloy, thickness, and finish of the sheets should be chosen based on the truck’s function and cargo requirements. Below is a table showing the suitable types of aluminum floor sheets for different truck types:

| Truck Type | Recommended Aluminum Alloy | Sheet Thickness | Pattern/Finish Type | Key Benefits |

| Pickup Trucks | 3003 Aluminum | 1.5-2 mm | Diamond Plate | Lightweight, corrosion-resistant, easy to install, and ideal for light-duty cargo. |

| Light Delivery Trucks | 5052 Aluminum | 2-2.5 mm | Checker Plate, Smooth Finish | Durable for regular use, good corrosion resistance, offers grip for packages or goods. |

| Heavy-Duty Freight Trucks | 6061 Aluminum | 3-4 mm | Checker Plate, Diamond Plate | High strength, suitable for heavy loads, resistant to wear, and offers excellent traction. |

| Refrigerated Trucks | 5052 Aluminum | 2-3 mm | Smooth or Embossed Finish | Corrosion-resistant, easy to clean, ideal for hygiene-sensitive environments like food transportation. |

| Dump Trucks | 6061 Aluminum | 4-5 mm | Diamond Plate or Smooth Finish | Superior strength to withstand heavy impacts from unloading, good wear resistance. |

| Flatbed Trucks | 6061 Aluminum | 3-4 mm | Checker Plate, Smooth Finish | Strong enough to support heavy cargo, anti-slip patterns for secure loading/unloading. |

| Tanker Trucks | 5052 or 5083 Aluminum | 2.5-3 mm | Smooth, Anti-Corrosion Coated Finish | Exceptional corrosion resistance for handling liquid or chemical cargo. |

2. Why Use Aluminum Floor Sheets for Truck Cargo Boxes?

Aluminum floor sheets are preferred in truck cargo boxes for several compelling reasons:

Lightweight but Strong

Aluminum is significantly lighter than steel, yet it offers comparable strength for many applications. This allows trucks to carry heavier loads without increasing the overall vehicle weight, improving fuel efficiency and reducing wear on the truck.

Corrosion-Resistant

Unlike steel, aluminum does not rust when exposed to moisture. This makes aluminum floor sheets ideal for trucks that operate in harsh weather conditions or humid environments. The corrosion resistance also ensures a longer lifespan for the cargo box, reducing the need for frequent repairs.

Easy to Maintain and Replace

Aluminum floor sheets are relatively easy to clean and maintain, reducing operational downtime. Should a section of the floor be damaged, replacing it is easier compared to steel or other materials, thanks to aluminum’s workability.

Eco-Friendly and Recyclable

Aluminum is 100% recyclable, making it an environmentally friendly option for manufacturers. Using recycled aluminum also requires less energy compared to producing new metal, contributing to a more sustainable supply chain.

3. How to Maintain Aluminum Floor Sheets for Truck Cargo Boxes?

Proper maintenance of aluminum floor sheets ensures that they last as long as possible and continue to provide high performance over time. Here are some key steps in maintaining them:

- Regular Cleaning: Dirt, debris, and corrosive substances such as salt or chemicals can accumulate on the floor sheets. Regular cleaning with mild detergent and water can prevent buildup, which could affect performance or lead to surface staining. Pressure washing is also a useful method to clean off stubborn dirt.

- Inspect for Damage: Although aluminum is durable, heavy impacts from loading and unloading can cause dents or scratches. Regular inspections help detect these damages early, allowing for timely repairs to prevent further deterioration.

- Prevent Oxidation: While aluminum naturally forms a protective oxide layer, exposure to harsh chemicals can sometimes cause pitting or surface oxidation. Using appropriate coatings, such as anodizing, can enhance the sheet’s protection against these elements.

- Avoid Harsh Chemicals: Harsh cleaners or solvents can damage the protective oxide layer or anodized finish on the aluminum floor sheets. Stick to mild detergents and avoid acidic or alkaline cleaners that can cause pitting.

- Monitor Fasteners and Joints: The fasteners used to secure the aluminum floor sheets to the truck frame can loosen over time due to vibrations. Regularly checking and tightening these fasteners ensures the sheets remain securely in place.

Aluminum floor sheets are an excellent choice for truck cargo boxes due to their lightweight yet strong nature, resistance to corrosion, and ease of maintenance. By choosing the right alloy, pattern, and maintenance practices, you can significantly extend the lifespan of your truck’s cargo box while improving its efficiency. Understanding these three key points will help you make informed decisions, ensuring your truck performs at its best for years to come.