As a derivative of aluminum foil, aluminum foil tape is often used in our daily life and the production of factories. As one of the most common adhesion tools, this article summarizes the three most important knowledge points about aluminum foil tape. These knowledge points about aluminum foil tape are things you should know before using it.

Scope of application of aluminum foil tape

Aluminum foil tape is made of high-quality pressure-sensitive adhesive, with good viscosity, strong adhesion, anti-aging, and other effects! The thermal insulation performance is greatly improved, and the specifications are (0.05mm-0.08mm) * various widths and lengths. Aluminum foil tape is used for all aluminum foil composite joints, sealing of insulation nail punctures, and repair of damage.

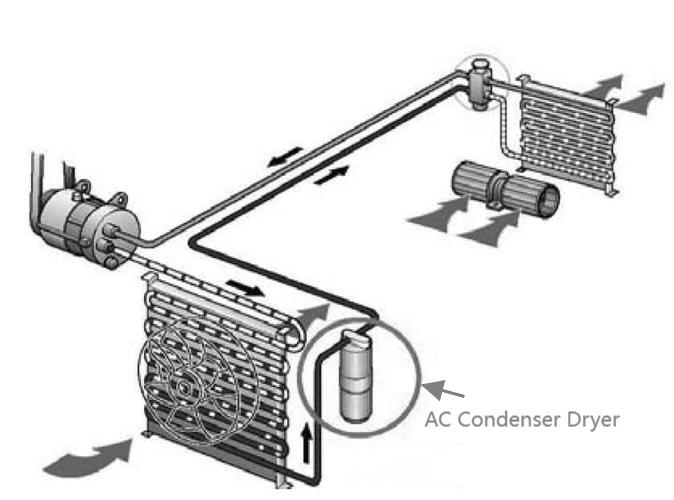

Aluminum foil tape is the main raw and auxiliary material for refrigerator and freezer manufacturers, and it is also a must-buy raw material for insulation material distribution departments. Aluminum foil tape is widely used in refrigerators, air, automobile, petrochemical, bridge, hotel, electronics, and other industries.

Aluminum foil tape can be used in places where electromagnetic shielding is required in various electronic products such as PDAs, PDPs, LCD monitors, notebook computers, and copiers. Aluminum foil tape is used to wrap the steam conduit to prevent the temperature from escaping outward.

One of the biggest features of aluminum foil tape is that it can isolate electromagnetic signals, and it is widely used in the field of electronic products.

For example, transformers, such as household notebook computers, and LCD monitors of desktop computers, are wrapped with aluminum foil tapes in these appliances to shield electromagnetic signals and accelerate the transmission of electronic signals.

Because of its isolation effect on electromagnetic waves, it also plays a role in preventing electromagnetic damage and protecting human health.

In the mobile phones, we play with all day, aluminum foil tape is also used to shield electromagnetic signals.

Aluminum foil tape also has a very powerful performance: anti-ultraviolet, and anti-corrosion.

With this resistance, aluminum foil tape is also useful in many extremely harsh and harsh environments, especially in oil and gas pipelines in urban construction and housing construction, as well as petrochemical transportation pipelines, aluminum foil tapes can be seen.

In addition to high strong and self-adhesive, aluminum foil tape is specially used to protect these pipes and tower structures, and it is a bright spot in the industrial industry.

It is still isolated as if the aluminum foil tape is a heartless master, electromagnetic signals can be shielded, and ultraviolet rays cannot pass through. It is unimaginable that, as a tape, the ordinary transparent tape is soft when it encounters fire, and it burns quickly. There is a kind of Aluminum foil tape that is fire-retardant and flame-retardant.

The production of this aluminum foil tape adopts a very innovative and cutting-edge technology. It is composed of aluminum foil, silicone release paper, glass fiber cloth, and a high-end material-coated with a strong flame-retardant acrylic adhesive. . Such aluminum foil tapes are generally used in the sealing and repair of fire insulation nail penetration and air conditioning duct systems.

Aluminum foil tape vs other tapes

The difference between aluminum foil tape and ordinary tape is mainly summarized in the following three aspects:

1. The base material of the aluminum foil tape is a soft polymer resin plate. Compared with gravure printing, it not only reduces the plate-making cost and shortens the plate-making cycle, and due to the improvement of the plate manufacturing level and plate-making technology, the screen plate can now be used. The level of 175 lines is enough to meet the needs of general packaging printing.

2. The aluminum foil tape uses an anilox roller to transfer ink. Since the anilox roller is both an ink transfer roller and an ink metering roller, it realizes the same short ink path as gravure printing, and can accurately supply ink according to the process requirements. At present, the laser is used. The engraved metal ceramic anilox roller can reach the level of 1600 lines, which provides a favorable means for accurately controlling the ink color and ink layer thickness.

3. The zero-pressure printing of aluminum foil tape not only reduces the vibration and wear of the machine, reduces the wear of the plate, but also expands the range of printing media, especially for the printing of flexible materials.

What to pay attention to when using aluminum foil tape

1. The purity of the aluminum foil tape is higher than 99.95%. Its function is to eliminate electromagnetic (EMI) interference, isolate the damage of electromagnetic waves to the human body and avoid the need for voltage and current to affect the function.

2. Aluminum foil tape has a good effect on electrostatic discharge after grounding.

3. The material of the aluminum foil tape is polyester fiber, which is not easy to crack and damage after repeated use or multiple bending.

4. The aluminum foil tape has strong adhesion and good electrical conductivity, and aluminum foil tape can be easily wound and attached to the wire.