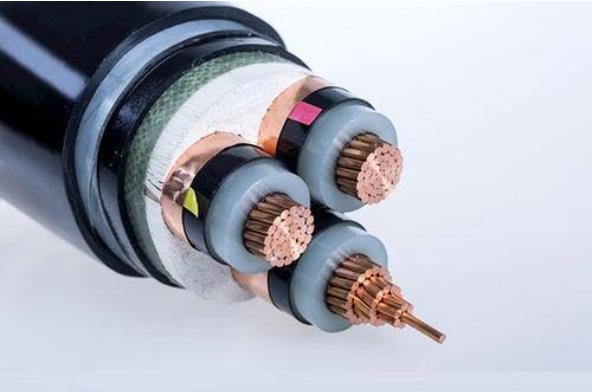

At present, the weight of copper wires in automotive wiring harnesses accounts for 75%. As the future development trend of the automotive wiring harness is lighter and thinner, less and less copper wire will be used. At present, the main method of replacing copper wire is aluminum wire instead of copper wire.

Advantages of applying aluminum conductors in automobiles

Aluminum (Al) wire is about two-thirds lighter than copper (Cu) wire, and this lightweight material reduces the overall weight of the cable harness. Even accounting for the relationship between conductivity and density, an aluminum wire with the same electrical resistance is still about 50% lighter than an equivalent copper wire.

In addition to being lighter, aluminum wire is a plentiful and readily available base material for conducting electricity. In comparison, copper wire has limited resources and is an “investment” metal. This means that the price of aluminum wire will be relatively stable and much lower than the price of copper wire, and the cost will be better controlled.

From the perspective of installation cost, because the aluminum wire is relatively light, it does not require bridges and pipes during the installation process, which can save a lot of installation materials, saving 20%-50% of the installation cost compared to copper wires.

Technical difficulties in applying aluminum wires to automobiles

Although aluminum wire has the advantages of being lightweight and low priced, it is rarely used in automobiles, and aluminum wire with small diameters is hardly involved. The reason is mainly that copper wires of 0.35mm² and 0.5mm² are used in the largest amount in automobile wiring harnesses, and the existing technology cannot completely solve the mechanical and electrical performance problems of small-diameter aluminum wires, so it is limited. The specific technical difficulties in the application of aluminum wire are as follows:

The conductivity of aluminum wire is about 60% of that of copper wires, so the relative ampacity is relatively low.

The mechanical strength of aluminum wire is only one-third of that of copper wire, which will affect the terminal crimping pull-off force.

An oxide film is easily formed on the surface of the aluminum wire, and the oxide layer has insulating properties, which will cause an increase in crimping resistance.

The electrode potential difference between copper and aluminum is about 2V. If the copper terminal is crimped with an aluminum wire, when the connection between copper and aluminum is in a humid environment, and a chemical medium dissolves in water vapor to form an electrolyte, aluminum is formed as the negative electrode. Copper is the positive electrode of the primary battery so the aluminum with a negative potential is corroded and dissolved, that is, electrochemical corrosion occurs.

The connection method of aluminum wire used in automobiles

There are three ways to connect the aluminum wire. The following three ways are suitable for copper and aluminum wire connections.

- Ultrasonic metal welding

The principle of ultrasonic metal welding is to use the vibration energy of ultrasonic frequency (20-40kHz) to transmit vibration waves to the surfaces of two metal objects to be welded, and under static pressure, the two metal surfaces rub against each other to form a molecular layer fusion between.

- Friction welding

As the name suggests, friction welding mainly uses friction. Although the metal surface looks very smooth, it is very uneven at the microscopic level. When two metal blocks rub against each other, the rough surface will generate a lot of heat energy due to the relative motion, and if the relative motion speed is accelerated and a huge pressure is applied at the same time, the heat generated at this time can melt the metal and wait until it cools down. The two pieces of metal are joined together.

- Plasma welding

Plasma welding is a welding method that uses a plasma arc as a heat source to melt the junction of two metals.

If you want to know more about aluminum wire applications, CHAL, a reliable professional aluminum manufacturer, will provide high-quality service and production to every customer. If there are any questions, please contact us.