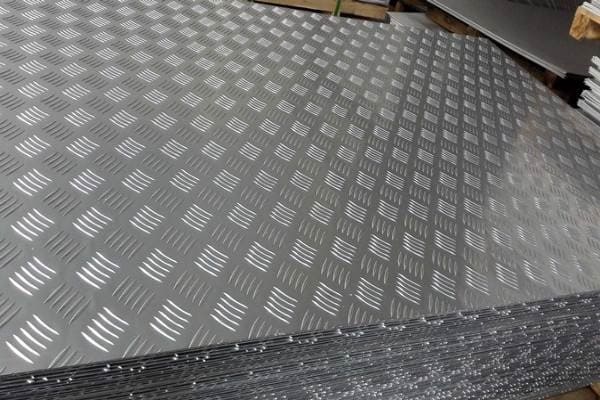

A tread plate is a form of metal stock with a regular pattern or lines on one side for slip resistance. It is also referred to as a checker plate and diamond plate. The most popular alloy for making aluminum tread plates is 6061, however other options include 5086-H34 and 3003-H231. Aluminum checker plates are perfect for a variety of uses in a variety of industries, from food processing to the production of cars and maritime equipment.

What is an aluminum tread plate?

An aluminum tread plate sometimes called an aluminum checker plate or occasionally spelled “aluminum chequer plate,” is a form of metal tread plate with characteristic raised bars that provide users with a non-slip surface. This makes it incredibly flexible for various sectors. Aluminum chequer plates are not only corrosion-resistant, lightweight, and easy to produce, but also non-slip.

Application areas for aluminum tread plates

Although very light, the aluminum corrugated sheet is a remarkably durable material. Permanent wetness, wind, and dirt are not problematic stresses. This makes our aluminum chequer plate perfect for outdoor use because tripping is impossible, even on steps or ramps. The sheet is suitable for numerous additional applications due to its high level of slip resistance and the associated safety that the diagonally ribbed structure offers. These, for instance, include:

- Various coverings

- Lining of rooms

- Flooring for trailers, ships, etc.

- Floor covering e.g. in vehicles such as trucks

- Ramps or steps

- Industry / metal construction / trade fair construction

Classification of aluminum tread plates

The patterned aluminum plate can be made of 1060 aluminum plate, 3030 aluminum plate, 5052 aluminum plate, 5083 aluminum plate, and other alloy grades of the aluminum plate as the substrate. According to the different substrates, the use and performance of the patterned aluminum plate are also different. You will introduce in detail the separation of patterned aluminum plates according to the different aluminum plate alloys:

The first type, an ordinary aluminum alloy pattern aluminum plate: aluminum alloy pattern plate processed with 1060 aluminum plate as the base plate, can adapt to the ordinary environment, and the price is low. Usually cold storage, floors, and outer packaging use this patterned aluminum sheet.

The second type, aluminum alloy pattern aluminum plate: is processed with 3003 as the main raw material, this kind of aluminum plate is also called an anti-rust aluminum plate, the strength is slightly higher than that of ordinary aluminum alloy pattern plate, and it has certain anti-rust performance, but the hardness and The corrosion resistance cannot reach the 5000 series of patterned sheets, so this product is used in rust prevention with less stringent requirements, such as truck models and cold storage floors.

The third type, aluminum-magnesium alloy pattern aluminum plate: is processed from 5000 series aluminum plates such as 5052 or 5083, with good corrosion resistance, hardness, and rust resistance. Usually used in special places, such as ships, carriage lights, and humid environments, this kind of aluminum plate has high hardness and a certain load-bearing capacity.

Why do aluminum tread plates have patterns?

1. Anti-skid: The anti-skid function is the main essential difference between the patterned aluminum plate and the aluminum plate or the alloy aluminum plate. I believe that everyone uses the patterned aluminum plate in the bus compartment, and the biggest effect of using it in the bus compartment is mainly anti-slip;

2. Wider scope of application: Don’t think that this can make the aluminum plate look better. In fact, in addition to this beautification effect, compared with ordinary aluminum plates, its anti-corrosion ability is stronger, the hardness is higher, and the elasticity is better, so more This kind of aluminum plate will be used in industries and fields;

3. There are many places where patterned aluminum plates are used in the aerospace industry. The general material is an aluminum-magnesium-gold plate, which has good elasticity, high hardness, strong pressure resistance, and anti-corrosion. effect.

How to install an aluminum tread plate?

The screw head is not exposed to the connection method, that is, one end of a patterned aluminum slat is fixed with a screw, and one end of the other patterned aluminum plate goes deep into a part, just to cover the screw. In terms of the effect of the façade, because there is a 6mm gap between the patterned aluminum slats There are gaps in the section, it forms a vertical concave line angle, which enriches the facade of the building and breaks the monotonous feeling.

If the patterned aluminum plate is a steel skeleton, you can first use an electric drill to drill a hole in the direction where the screw is screwed. The hole diameter should be determined according to the standard of the screw, and then tighten the patterned aluminum plate with self-tapping screws. If it is a wooden skeleton, the patterned aluminum plate should be screwed directly into the skeleton with wood screws.

The gap between the patterned aluminum plate and the patterned aluminum plate is usually 5~10mm, which is treated with elastic materials such as rubber strips or sealants.