With the gradual maturity of aluminum processing technology, some complex surface treatments of aluminum profiles have flourished. We often see the surface treatment processes of aluminum profiles include electrophoresis, anodizing, and fluorocarbon coating spraying.

- Electrophoresis

Electrophoresis is the coating of yin and yang to Dianlingdong. Under the action of voltage, the charged paint ions move to the cathode. The aluminum profile surface treatment manufacturer believes that insoluble substances are formed under the act of alkalinity generated on the surface of the cathode and deposited on the surface of the workpiece. Aluminum electrophoresis means placing extruded aluminum alloy products in an electrophoresis tank. Under the stimulation of direct current, a resin film with a dense appearance is formed on the surface of the aluminum profile product. Electrophoretic aluminum material is very bright, has a mirror effect, and has high corrosion resistance.

- Anodizing

Anodized aluminum material refers to the process in which aluminum and its alloys form an oxide film in an aluminum product (anode) under the action of an applied current under the corresponding electrolyte and specific process conditions. However, the oxide film formed by anodized aluminum differs from the ordinary oxide film. Anodized aluminum can be dyed with electrolytic coloring. To overcome the appearance, hardness, and wear resistance of aluminum alloys, expand the scope of application and prolong the service life, the surface treatment technology of aluminum profiles has become an indispensable part of the use of aluminum alloys. Anodizing technology is currently the most widespread and successful application.

Aluminum Profile Surface Treatment Process

Degreasing, chemical finishing, acid corrosion, shady, anodizing, dyeing, pretreatment, sealing, drying, the difference between anodizing and electrophoresis is first oxidized and then colored, and electrophoresis is directly colored.

- Electrostatic powder coating

The powder coating is sprayed onto the appearance of the workpiece by electrostatic sorting equipment. Under static electricity, the powder is evenly adsorbed on the appearance of the workpiece to form a powder coating. The spraying effect is far superior to the painting process in terms of mechanical strength, adhesion, corrosion resistance, and aging resistance.

- Fluorocarbon Spraying

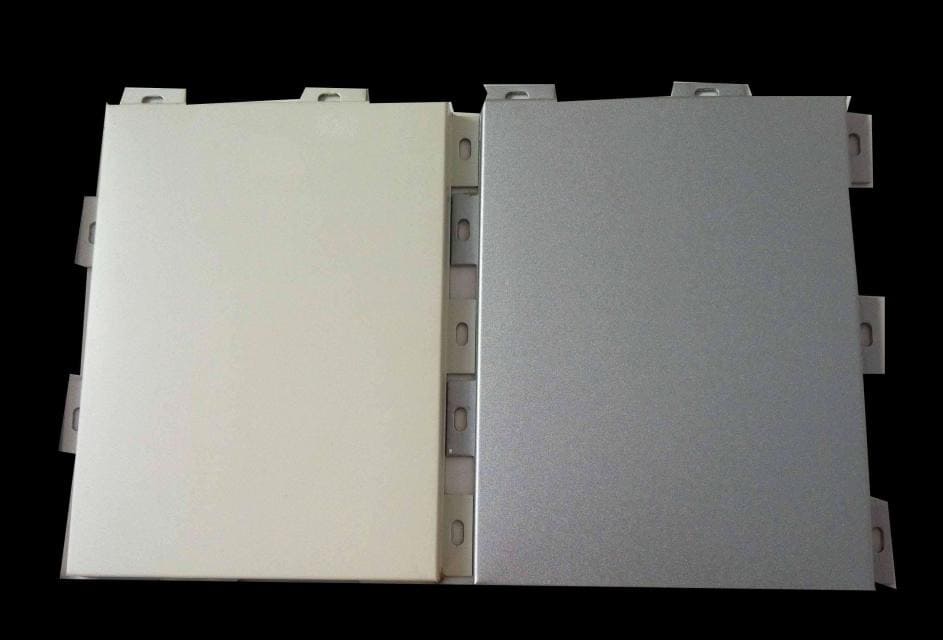

Fluorocarbon spraying is both an electrostatic spraying and a liquid spraying method. The fluorocarbon spray coating comprises polyvinylidene fluoride resin baked or metal aluminum powder. Suspended and semi-suspended, Suspension, i.e., the pretreatment and spraying of aluminum, suspends the aluminum during the curing process. The high-quality fluorocarbon coating has a metallic luster, bright color, and an apparent three-dimensional effect.

Pretreatment process: aluminum, degreasing, decontamination, washing, alkali washing (degreasing), water washing, chrome washing, pure water washing; spraying process: spraying primer topcoat baking (180 ~ 250) quality inspection.

The difference between electrostatic powder spraying and fluorocarbon spraying: The powder spraying process refers to using powder spraying equipment (electrostatic sprayer) to spray powder coating on the surface of the workpiece so that the powder is evenly adsorbed on the surface of the workpiece to form a powder coating. Fluorocarbon spray is an electrostatic spray, a liquid spray method known as fluorocarbon spray, and Hong Kong is called actinide oil.

- Wood Grain Transmission

Wood grain steel is based on powder spraying or electrophoretic coating, according to high-temperature sublimation and heat penetration principles. Through heating, pressurizing, and radiating the wood grain pattern on the paper or the whole human film, it can quickly die, penetrate spray, or electrophoresis well. The wood grain steel produced is precise, the three-dimensional effect is strong, and the wood grain is more prominent. The natural feeling is an ideal energy-saving and environmentally friendly material to replace traditional wood.

Conclusion

CHAL is the best material in both views from the cost material, as it improves efficiency and causes aluminum profiles to function at a higher level. If you’re looking for a reputable manufacturer of aluminum profiles, get in touch with us. Our team is qualified and has years of expertise in making aluminum tubes, aluminum plates, and aluminum foils. We can provide you with the best aluminum alloy products from China.