Aluminum finned tubes are a kind of aluminum processing parts that are often seen in our lives, such as air conditioners and air conditioners.

So what exactly are finned tubes? What are the classifications of finned tubes? What is the appearance and shape of the product? What are the product structure and features? What material are they made of? With these questions, we understand finned tubes and finned tube radiators from 4 aspects.

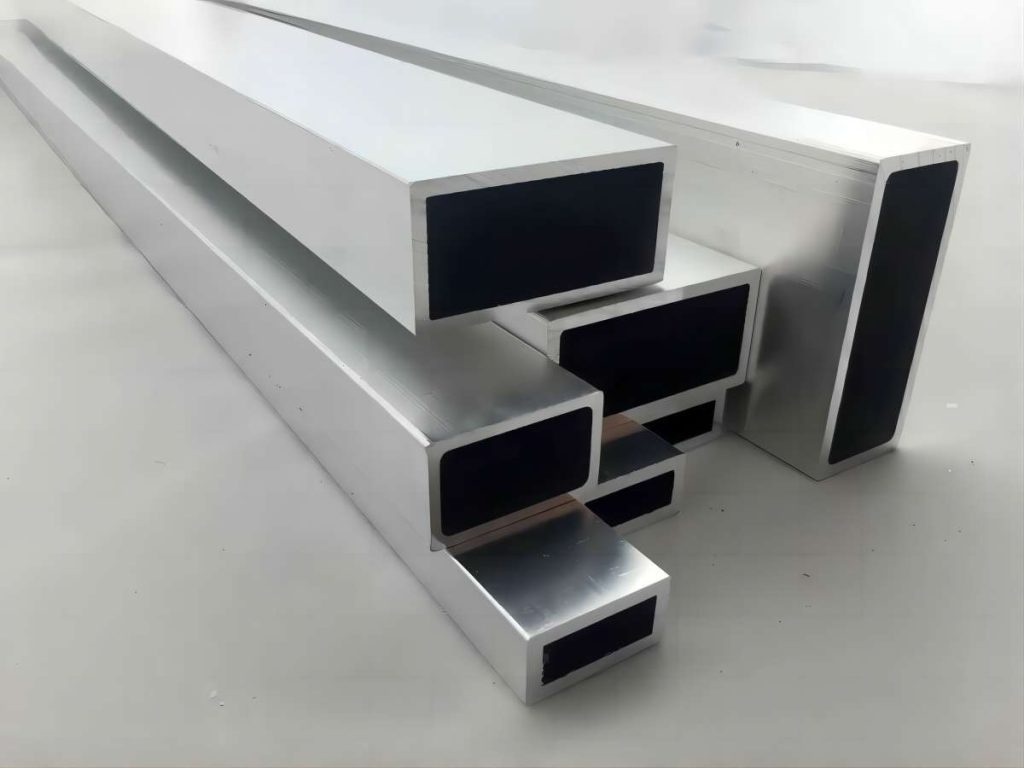

1. Definition of finned tubes

The finned tube is a heat exchange element, mainly to improve the heat exchange efficiency, usually by adding fins on the surface of the heat exchange tube to increase the outer surface area (or inner surface area) of the heat exchange tube, to improve the heat exchange efficiency.

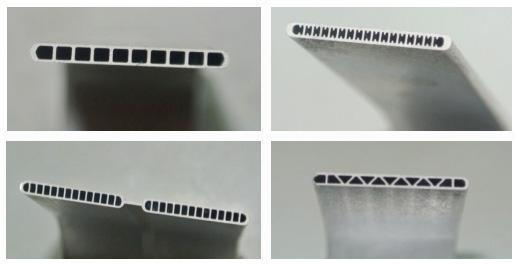

2. Types of aluminum finned tubes

At present, the most common and widely used finned tubes are divided into 3 categories: extruded aluminium finned tubes, winding finned tubes, and high-frequency welded finned tubes.

(1) Extruded aluminum finned tubes

Extruded aluminium fins are effectively in the form of a base tube sleeved with an aluminum tube. (The base tube can be extruded from carbon steel, stainless steel, and copper) to form fins. The coefficient is high and the heat transfer performance is excellent.

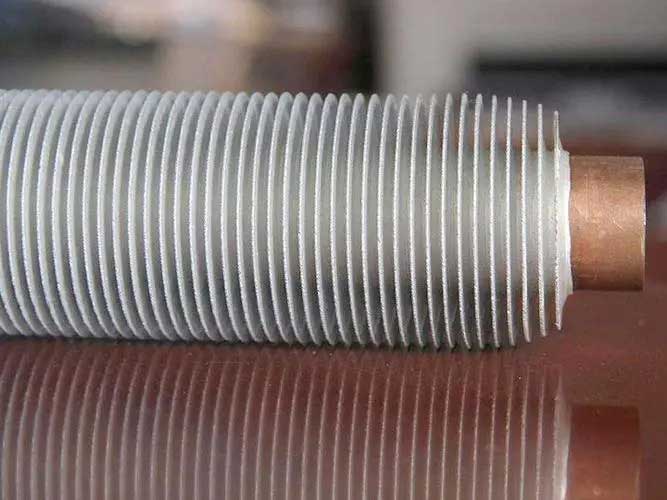

(2) Winding finned tubes

The tube-wound finned tube is in the form of a base tube wrapped around a steel strip, which can be (copper, aluminum, carbon steel, or stainless steel). This type of finned tube is suitable for various types, such as stainless steel coiled tubes, which can be suitable for occasions with high-quality requirements.

(3) High-frequency welded tubes

High-frequency welded pipes are mostly used for base pipes with a diameter of 10-219mm. The fins are welded on the surface of the base pipe using the principle of high-frequency welding. This type of finned tube has a high heat transfer coefficient and a high fin thickness, which is stronger than other finned tubes, and the fins are relatively difficult to damage. Long service life and good effect.

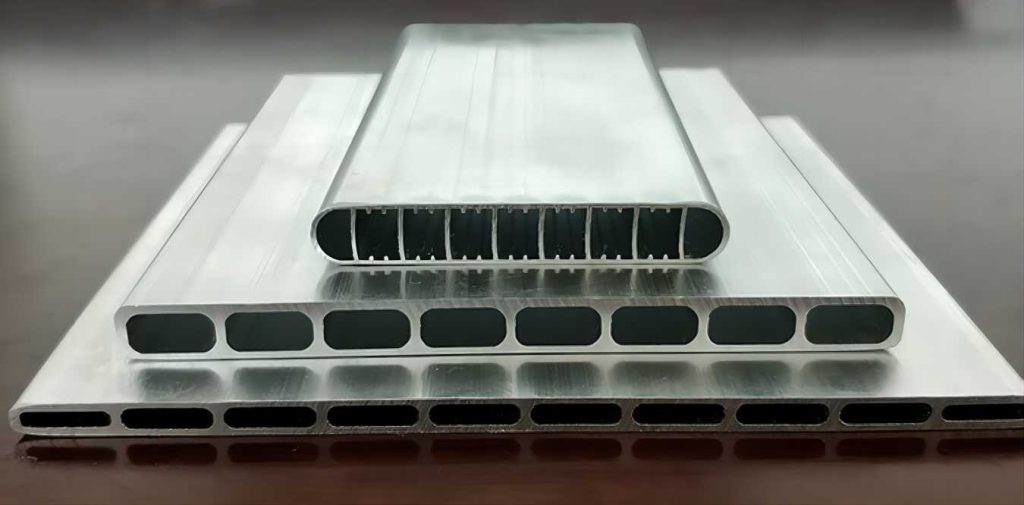

3. The structure and characteristics of the finned tube radiator

The finned tube is integrally rolled from aluminum tubes, with no contact thermal resistance, high strength, thermal shock, and mechanical shock, good thermal expansion performance, and a considerably extended heat exchange surface. The heat exchanger made of this kind of finned tube is better than the string or wound fin heat exchanger.

4. Advantages of hot-dip galvanized finned tube radiators

Hot-dip galvanized finned tube radiator refers to a high-quality seamless steel tube, through a special winding machine, the high-quality steel strip is tightly and evenly wound on the outer surface of the base tube by mechanical force, and the two ends are spot welded to fix; Then the whole steel finned tube is hot-dip galvanized.

The galvanized layer allows the finned tube to form a special metallurgical structure that can withstand mechanical damage during transportation and use.

Every part of the plated part can be galvanized for full protection even in depressions, sharp corners, and hidden places. Relatively speaking, it has stronger corrosion resistance and protection ability than ordinary finned radiators.

5. The price of aluminum finned tubes

Compared with steel finned tubes, aluminum finned tubes are cheaper and lighter in weight, which can effectively reduce the weight of products.

Compared with other aluminum finned tube manufacturers, CHAL’s aluminium finned tubes have lower prices, and they are completely affordable.