As for the 6063 aluminum tube, what exactly does it refer to? Today, this article will introduce you to everything about the 6063 aluminum tube.

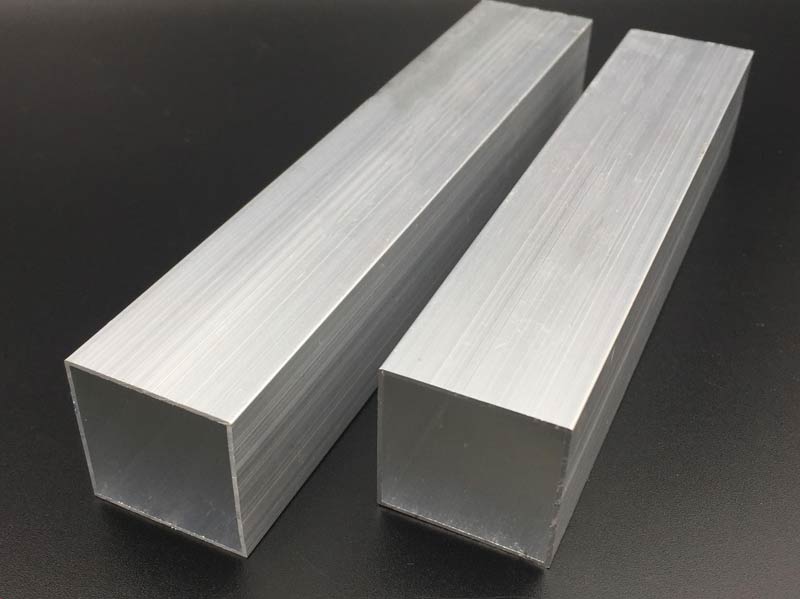

What is the 6063 aluminum tube?

The 6063 aluminum tube is a representative aluminum alloy for extrusion. The strength of the 6063 aluminum tube is lower than that of the 6061 aluminum tube but the extrudability of the 6063 aluminum tube is good. It can be used as a profile with complex cross-sectional shapes. Besides, this aluminum tube has good corrosion resistance and surface treatment. Thus, the 6063 aluminum tube is suitable for the construction of road guardrails, vehicles, furniture, and home appliances decorations.

What are the features of the 6063 aluminum tube?

1. Strengthened by heat treatment, high impact toughness, insensitive to defects.

2. It has excellent thermoplasticity and can be extruded at high speed into complex, thin-walled, and hollow profiles or forged into forgings with complex structures. The quenching temperature range is wide, and the quenching sensitivity is low. After extrusion, forging, and demolding, as long as the temperature is higher than the quenching temperature. That is, it can be quenched by spraying water or piercing water. Thin-walled parts (6<3mm) can also be air quenched.

3. Excellent welding performance and corrosion resistance, with no tendency of stress corrosion cracking. Among heat-treatable aluminum alloys, Al-Mg-Si alloys are the only alloys without stress corrosion cracking.

4. After processing, the surface is very smooth and easy to anodize and color. The disadvantage is that if it is parked at room temperature for some time after quenching and then aged, it will harm the strength (parking effect).

What is the relationship between 6063 aluminum tube T5 and T6?

The 6063 aluminum tube is a hollow metal tubular material that is extruded from an aluminum alloy along its entire longitudinal length. The 6063 aluminum tubes T5 and T6 are both heat treatment methods. The 6063 aluminum tube T5 is that after the aluminum profile is extruded from the extruder, the aluminum profile is cooled rapidly by air cooling to meet the hardness requirement of the aluminum tube.

The 6063 aluminum tube T6 is the aluminum profile that is extruded from the extruder and cooled by water to instantly cool the aluminum profile so that the aluminum profile can meet higher hardness requirements.

The 6063 aluminum tube T5 is generally air-cooled when quenched in the profile factory, and the 6063 aluminum tube T6 is generally water-cooled when quenched in the profile factory. Both have the same modulus of elasticity. Under normal circumstances, the T5 state is used. If the deflection of the rod passes but the tensile strength is slightly worse, the T6 state can be used. The strength of T6 is better than T5, but T6 is generally more expensive than T5.

What needs to know about Cutting 6063 Aluminum Tube?

Sawing is the general method to cut 6063 aluminum tubes. When cutting 6063 aluminum tubes by sawing, to get a neat saw seam, it should be sawed in one direction from the beginning to the end. If the requirements for the section are not high, the sawing direction can be gradually changed to reduce the resistance and facilitate cutting.

When the grinding wheel is cutting the 6063 aluminum tube, if there is vibration, shaking, or instability, you need to stop the operation immediately. Next, you should check whether the grinding wheel is notched or damaged. If so, it must be replaced in time to ensure safe and regular use. The operator must not stand on the side with the grinding wheel when the machine is running to avoid accidents. If there are burrs on the surface of the cut 6063 aluminum tube, it can be processed and smoothed with a grinding wheel or a file.

What factors cause the quality of 6063 aluminum tubes?

1. The raw material quality of 6063 aluminum tubes: high-quality pig iron, low phosphorus, and low sulfur.

2. Modularization rate standard: Improve the modularization rate standard. After the 6063 aluminum tube meets the standard, the aluminum tube can enter the next process.

3. Quality defects of the aluminum tube in the casting process: sand inclusions, sand holes, and pinholes are caused by the mold, and the mold needs to be repaired in time.

4. Anneal the 6063 aluminum tube to eliminate stress. Annealing is maintained at an appropriate temperature. Only when the annealing is good, the 6063 aluminum tube will have good physical properties.

5. Finished product defect repair: When a defective aluminum tube is found, the aluminum tube will be handled by the situation. If the aluminum tube can be repaired, it will enter the repair program. If it is not repairable, it will be treated as a waste aluminum tube.