72-M Type Alumina PCW Fiber

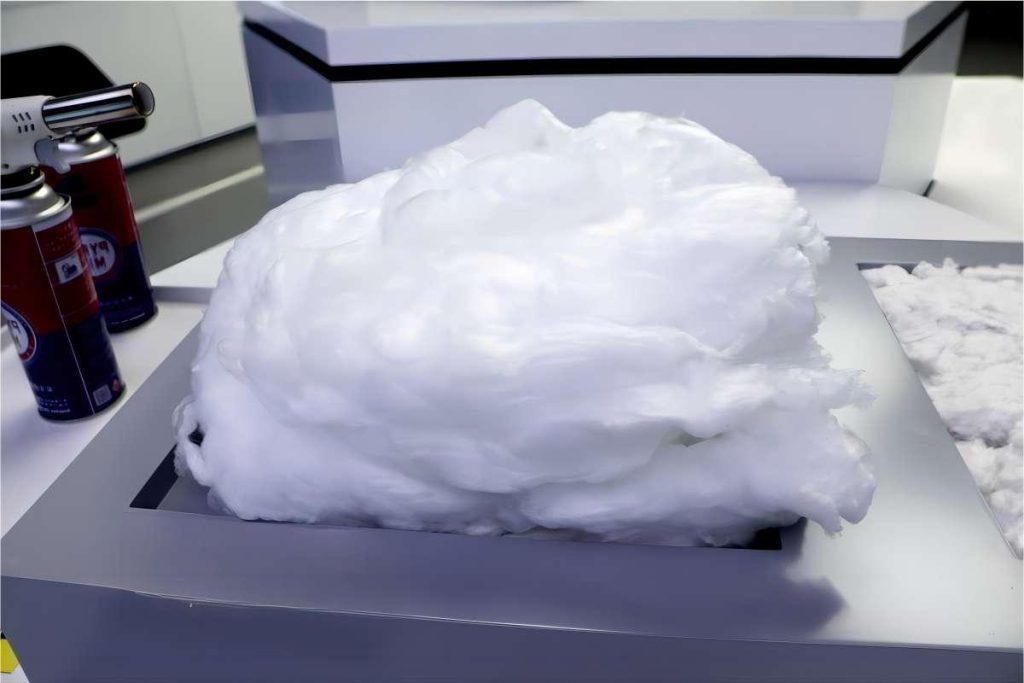

The 72-M type alumina PCW fiber demonstrates remarkable stability at high temperatures and in chemical environments. It finds extensive application in the manufacturing of high-temperature products, including high-temperature fiberboard, fiber profiled parts, fiber blanket, fiber felt, and fiber paper. Moreover, it is widely employed for high-temperature insulation across various industries such as steel, petrochemicals, ceramics, sealing, and heat insulation.

Product Introduction

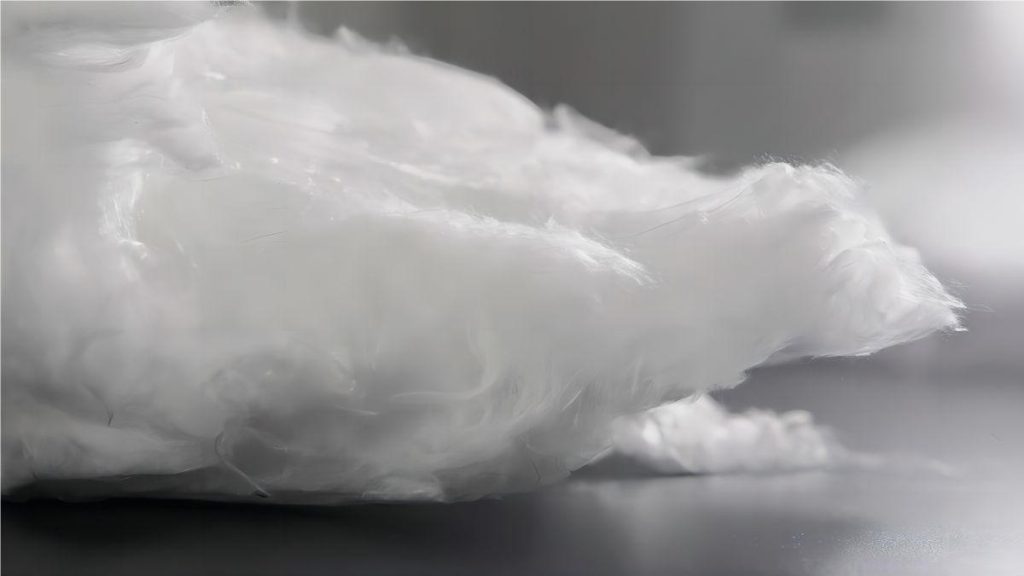

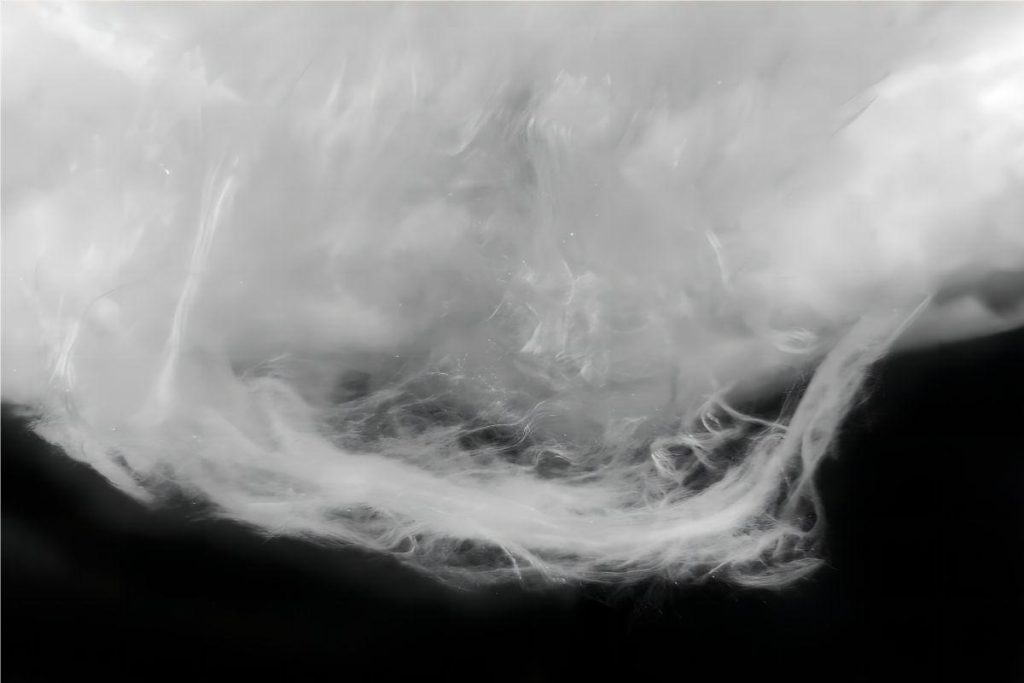

The 73-M type alumina short fiber is primarily comprised of 72% Al2O3 and 28% SiO2, prepared using the advanced “sol-gel” method recognized globally. This fiber exhibits performance indicators that rank among the highest internationally. Notably, it possesses exceptional flexibility, fire resistance, and thermal insulation properties.

Product Performance

Excellent High and Low Temperature Resistance

Al2O3 Fibre can withstand service temperatures ranging from 1400℃ to 1800℃. Remarkably, even after being exposed to liquid nitrogen (-196℃) for 24 hours, the fiber’s strength remained unaffected.

Acid and Alkali Resistance

After immersing in a 10% alkali solution for 24 hours, the fiber strength retention rates are as follows: NaOH—40%, KOH—65%, and NH4OH—95%. Similarly, the fiber strength retention rates after soaking in a 10% acid solution for 24 hours are as follows: HCl—96%, H2SO4—95%, HNO3—96%, and H3PO4—95%.

Slag Free Ball

Our fiber is free from shot particles(≥45 μm). This absence of shot particles has contributed to an improvement in fiber strength. Additionally, the thermal insulation and fire resistance of the fiber are inversely proportional to the shot content. In other words, the lower the shot content, the higher the thermal insulation and fire resistance properties of the fiber.

Excellent Electrical Insulation

The electrical resistance of alumina fiber shows a decline as the temperature rises. Once the temperature surpasses 600℃, the resistance tends to remain relatively stable. Moreover, the dielectric constant and dielectric loss of alumina fiber exhibit consistent values at high temperatures, making it a suitable material for high-temperature wave transmission applications.

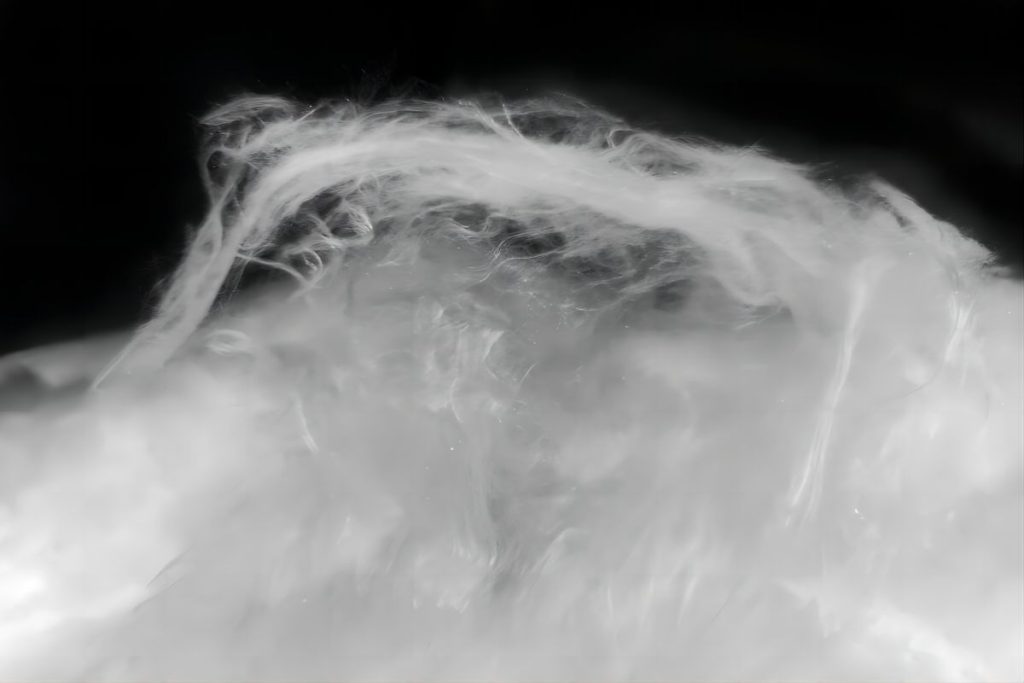

Excellent Flexibility

Excellent flexibility: The fiber demonstrates remarkable flexibility, making it highly resistant to breakage during the acupuncture process. It is an exceptionally well-suited product for acupuncture procedures.

Strong Design

Through the adjustment of chemical composition and heat treatment processes, it is possible to obtain products with diverse properties that can cater to various application requirements.

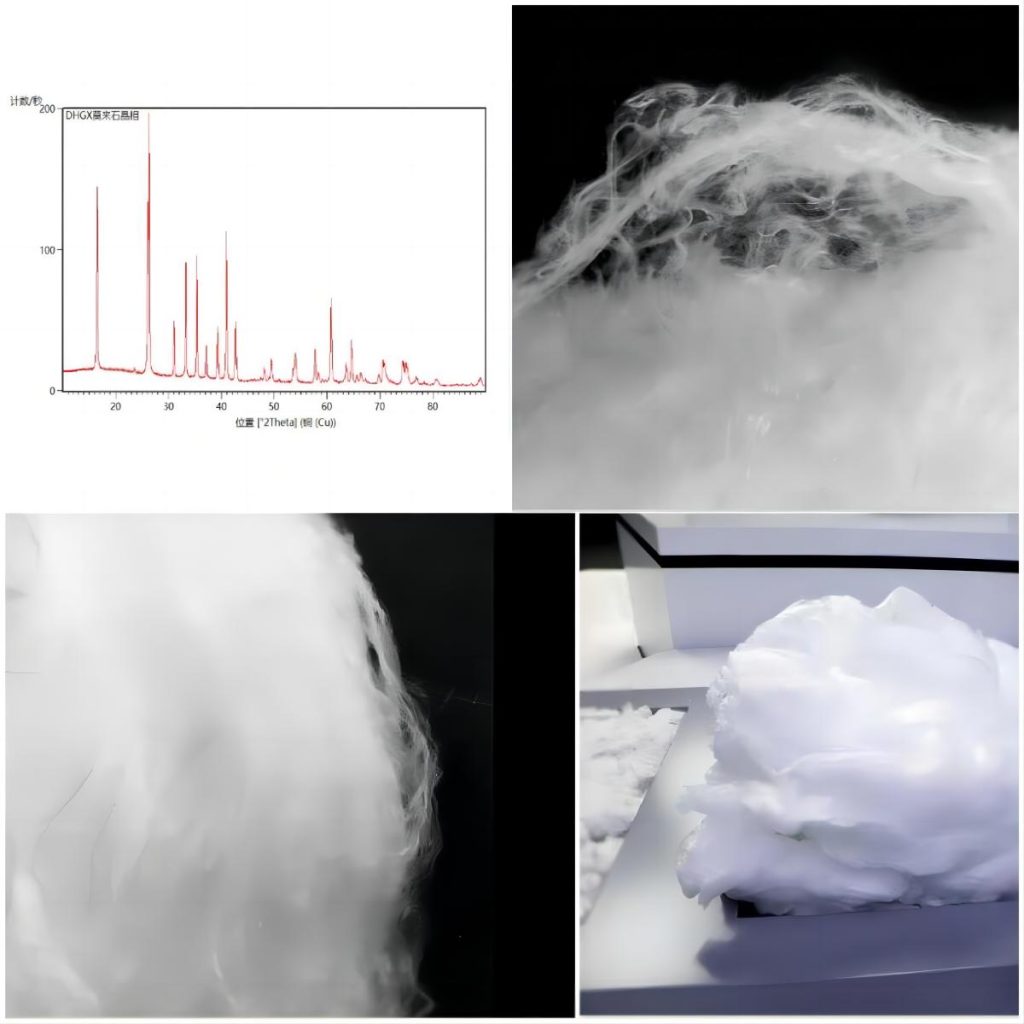

Technical Parameter

|

Product Type |

Type 72-M |

|

|

Chemical Composition Al2O3:SiO2 (%) |

72-75:25-28 |

|

|

Mineral Structure |

Mullite |

|

|

Classification Temperature (℃) |

1600 |

|

|

Molten Point (℃) |

>1800 |

|

|

Density (g/cm3) |

3.1 |

|

|

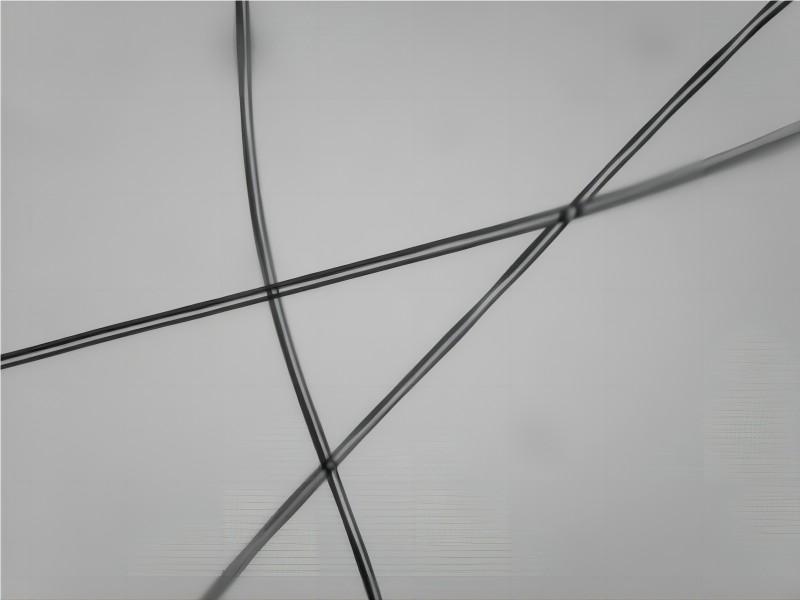

Average Fibre Diameter (μm) |

5.5-7.5 |

|

|

Length (cm) |

3-10 |

|

|

Shot Content (%) |

≥45μm |

0-2 |

|

Impurity (%) |

<0.5 |

|

|

Tensile Strength (MPa) |

≥1200 |

|

|

Modulus of Elasticity (GPa) |

≥100 |

|

|

Slip casting during 1h (%) |

1600℃下≤1 |

|

Typical Applications

The 72-M type alumina PCW fiber exhibits exceptional stability at high temperatures and in chemical environments. It is extensively employed in the production and manufacturing of various high-temperature products, including high-temperature fiberboard, high-temperature fiber profiled parts, fiber blanket, fiber felt, and fiber paper. Moreover, it finds wide application in high-temperature insulation across industries such as steel, petrochemicals, ceramics, sealing, and heat insulation.

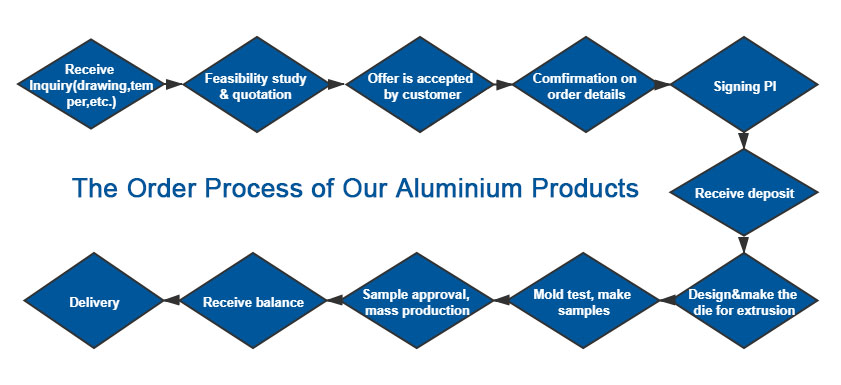

Order Process of 72-M Type Alumina PCW Fiber