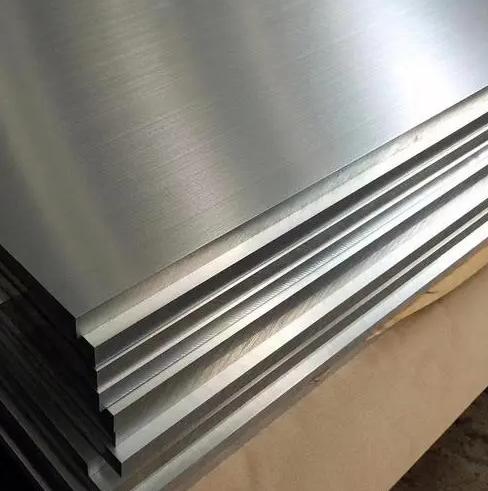

The parts materials we are familiar with include aluminum plate, aluminum tube, steel, stainless steel, etc. But you know what? The fatigue strength of materials is extremely sensitive to various external and internal factors. In the processing of aluminum and other parts materials, many factors affect the fatigue strength of materials.

External factors include the shape and size of the part, surface finish, and conditions of use. Intrinsic factors include the composition of the material itself, tissue state, purity, and residual stress.

Subtle changes in these factors can cause fluctuations or even large changes in the fatigue properties of materials.

The influence of various factors on fatigue strength is an important aspect of fatigue research. This research will provide the basis for the reasonable structural design of parts, as well as the correct selection of materials and the rational formulation of various cold and hot processing processes to ensure that the parts have high fatigue performance.

1. The Effect Of Stress Concentration On Materials

The conventional fatigue strength is measured with carefully machined smooth specimens. However, actual mechanical parts inevitably have different forms of notches, such as steps, keyways, threads, and oil holes. The existence of these gaps causes stress concentration so that the maximum actual stress at the root of the gap is much larger than the nominal stress of the part, and the fatigue failure of the part often starts from here.

Theoretical stress concentration factor Kt: the ratio of the maximum actual stress to the nominal stress at the root of the notch, obtained from the elastic theory under ideal elastic conditions.

Effective stress concentration factor (or fatigue stress concentration factor) Kf: the ratio of the fatigue limit σ-1 of the smooth sample to the fatigue limit σ-1n of the notched sample.

The effective stress concentration factor is not only affected by the size and shape of the component, but also by the physical properties of the material, processing, heat treatment, and other factors.

The effective stress concentration factor increases with the sharpness of the notch but is usually smaller than the theoretical stress concentration factor.

Fatigue notch sensitivity coefficient q: The fatigue notch sensitivity coefficient indicates the sensitivity of the material to the fatigue notch, and is calculated by the following formula.

The data range of q is 0-1, and the smaller the q value, the less sensitive the material is to notches. Experiments show that q is not purely a material constant, it is still related to the size of the notch. Only when the radius of the notch is greater than a certain value, the value of q is independent of the notch, and the value of this radius is also different for different materials or processing states.

2. Influence Of Part Size Factors

Due to the inhomogeneity of the material itself and the existence of internal defects, the increase in size leads to an increase in the probability of material failure, thereby reducing the fatigue limit of the material.

The existence of the side effect is an important problem in applying the fatigue data measured by small samples in the laboratory to the large-size actual parts. reproduced on small samples, resulting in a disconnect between the laboratory results and the fatigue failure of some specific parts.

3. Influence of Surface Machining State of Parts on Fatigue Strength of Aluminum

There are always uneven machining marks on the machined surface. These marks are equivalent to tiny gaps, causing stress concentration on the surface of the material, thereby reducing the fatigue strength of the material. Tests have shown that for steel and aluminum alloys, rough machining (rough turning) reduces the fatigue limit by 10%-20% or more compared to longitudinal finishing. The stronger the material, the more sensitive it is to the surface finish.

4. Influence Of Material Loading Experience On Fatigue Strength

No part works under the condition of absolutely constant stress amplitude. The overload and secondary load in the actual work of the material will affect the fatigue limit of the material. The test shows that the material generally has overload damage and secondary load exercise phenomenon.

The so-called overload damage refers to the decrease of the fatigue limit of the material after the material has been operated under a load higher than the fatigue limit for a certain number of cycles. The higher the overload, the shorter the number of cycles required to cause damage, as shown in the diagram below.

In fact, under certain conditions, a small number of overloads will not only cause no damage to the material, but also strengthen the material due to deformation strengthening, crack tip passivation and residual compressive stress, thereby increasing the fatigue limit of the material. Therefore, some supplements and modifications should be made to the concept of overload damage.

The so-called sub-load exercise refers to the phenomenon that the fatigue limit of the material increases after a certain cycle of operation at a stress level lower than the fatigue limit but higher than a certain limit. The effect of the second load exercise is related to the performance of the material itself. Generally speaking, the material with good plasticity needs a longer exercise cycle and higher exercise stress to be effective.

5. Effect of Chemical Composition on Fatigue Strength of Metal Materials

Under certain conditions, the fatigue strength of the material is closely related to the tensile strength. Therefore, under certain conditions, any alloying element that can improve the tensile strength can improve the fatigue strength of the material. In contrast, carbon is the most important factor affecting the strength of the material. However, some impurity elements that form inclusions in steel have a detrimental effect on fatigue strength.

6. Effects of Heat Treatment and Microstructure on Fatigue Strength of Materials

Different heat treatment states will obtain different microstructures. Therefore, the effect of heat treatment on fatigue strength is essentially the effect of microstructure. Materials of the same composition, due to different heat treatments, can obtain the same static strength, but due to different structures, the fatigue strength can vary within a considerable range.

At the same strength level, the fatigue strength of flaky pearlite is significantly lower than that of granular pearlite. The same is granular pearlite, the finer the cementite particles, the higher the fatigue strength.

The influence of microstructure on the fatigue properties of materials is not only related to the mechanical properties of various structures but also to the grain size and the distribution characteristics of the structures in the composite structure. Grain refinement increases the fatigue strength of the material.

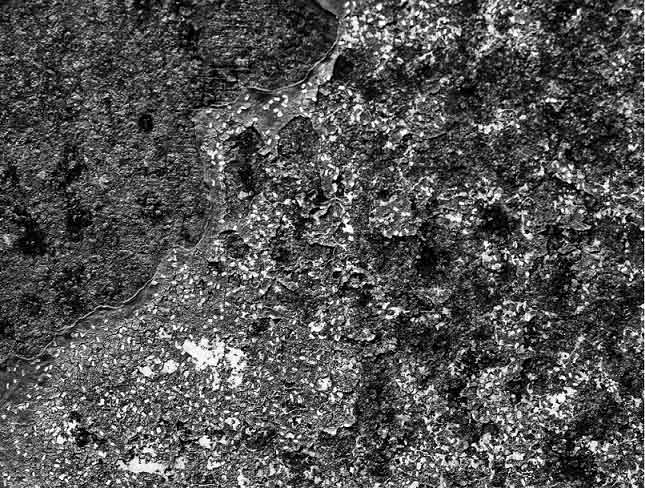

7. Influence of Inclusions on Material Fatigue Strength

The inclusions themselves or the holes generated by them are equivalent to tiny gaps, and under the action of alternating loads, stress concentration and strain concentration will occur, which will become the crack source of fatigue fracture, which will adversely affect the fatigue performance of the material.

The influence of inclusions on fatigue strength depends not only on the type, nature, shape, size, quantity, and distribution of the inclusions but also on the strength level of the material and the level and state of the applied stress.

Different types of inclusions have different mechanical and physical properties and have different effects on fatigue properties. Generally speaking, easily deformable plastic inclusions (such as sulfides) have little effect on the fatigue properties of steel, while brittle inclusions (such as oxides, silicates, etc.) are more harmful.

Inclusions with a larger expansion coefficient than the matrix (such as sulfide) have little influence due to the compressive stress in the matrix, while inclusions with a smaller expansion coefficient than the matrix (such as alumina, etc.) have a greater influence due to the tensile stress in the matrix.

How tightly the inclusions bond to the base metal also affects the fatigue strength. Sulfide is easy to deform and is closely combined with the base metal, while oxide is easy to detach from the base metal, resulting in stress concentration. It can be seen that from the type of inclusions, the influence of sulfides is small, while oxides, nitrides, and silicates are more harmful.

Under different loading conditions, the effects of inclusions on the fatigue properties of materials are also different. Under high load conditions, with or without the presence of inclusions, the applied load is sufficient to induce plastic rheology of the material, and the influence of inclusions is small.

In the material’s fatigue limit stress range, the presence of inclusions causes local strain concentration to become the controlling factor for plastic deformation, which strongly affects the material’s fatigue strength. That is to say, the existence of inclusions mainly affects the fatigue limit of the material, and has little effect on the fatigue strength under high-stress conditions.

The purity of the material is determined by the smelting process. Therefore, the use of purification smelting methods (such as vacuum melting, vacuum degassing and electro slag remelting, etc.) can effectively reduce the impurity content in the steel and improve the fatigue performance of the material.

8. The Effect Of Surface Property Change And Residual Stress On Material Fatigue Strength

In addition to the surface finish mentioned above, the influence of the surface state also includes changes in the mechanical properties of the surface layer and the influence of residual stress on the fatigue strength. The change in the mechanical properties of the surface layer can be caused by the difference in the chemical composition and structure of the surface layer, or it can be caused by the deformation and strengthening of the surface layer.

In addition to increasing the wear resistance of parts, surface heat treatment such as carburizing, nitriding, and carbonitriding are also an effective means to improve the fatigue strength of parts, especially corrosion fatigue and galling.

Contrary to chemical heat treatment such as carburizing, nitriding, carbonitriding, etc., if the carbon element is excluded during the heat treatment process, the surface strength of the part will be reduced, and the fatigue strength of the material will also be greatly reduced.

If induction quenching, surface flame quenching, and thin-shell quenching of low hardenability steel are used, a certain depth of surface hardness layer can be obtained, and favorable residual compressive stress is formed on the surface layer, so it is also an effective method to improve the fatigue strength of parts.

CHAL always insists on producing high-quality aluminum materials, aluminum sheets, and aluminum foils. In order to meet the needs of each customer, we provide customized services for aluminum processing materials to provide the best guarantee for your product production. If you need high-quality and low-cost aluminum sheets, aluminum foils, aluminum tubes, etc., you may try to contact us, we will be your most trusted partner.