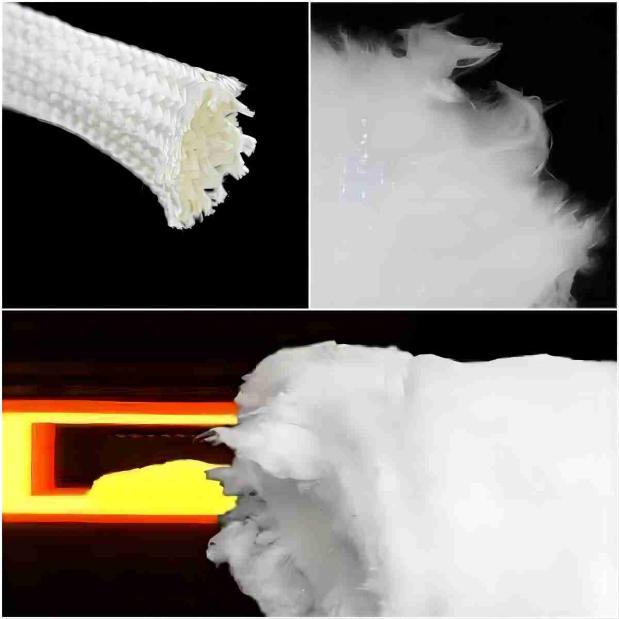

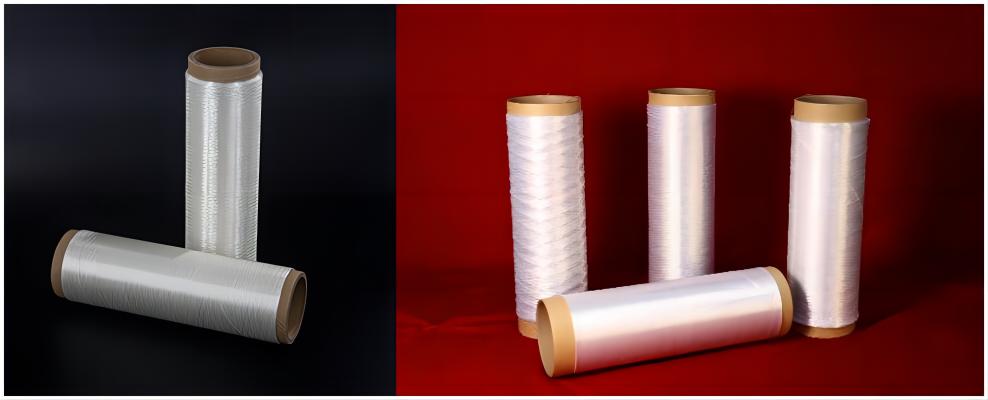

Alumina ceramic fiber textiles are high-performance textiles that can be used in a variety of high-temperature sealing and thermal shielding applications. They surpass the limitations of common high-temperature textiles and possess properties such as oxidation resistance, chemical inertness, lightweight, flexibility, fire resistance, and electrical insulation at high temperatures. This article will discuss the main application of aluminum oxide ceramic fiber textiles in different fields.

Properties of Alumina Ceramic Fiber Textiles

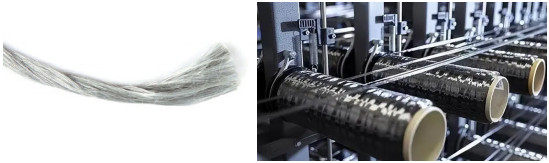

Aluminum ceramic fibers are made from aluminum oxide, which is a high-melting-point (2,040°C) and chemically inert material. This makes them ideal for use in high-temperature applications where other materials would degrade or fail. Alumina ceramic fibers are also lightweight and flexible, making them easy to work with and install. In addition, they are fire-resistant and provide excellent electrical insulation at high temperatures.

4 Main Applications of Alumina Ceramic Fiber Textiles

Alumina ceramic fiber textiles can be used in a variety of high-temperature sealing and thermal shielding applications, including:

- Door seals: Alumina ceramic fiber textiles are often used in door seals for industrial furnaces and ovens. These seals must be able to withstand high temperatures and thermal cycling, as well as the corrosive effects of gases and chemicals. Alumina ceramic fiber textiles are ideal for this application because they are lightweight, flexible, and fire-resistant. They are also resistant to chemicals and moisture, making them ideal for use in harsh environments.

- Rotary kiln seals: Rotary kilns are used in the cement and ceramic industries to heat and process materials. The seals that keep the kilns closed must be able to withstand high temperatures and abrasive wear. Alumina ceramic fiber textiles are an excellent choice for this application because they are lightweight, flexible, and fire-resistant. They are also resistant to chemicals and moisture, making them ideal for use in these harsh environments.

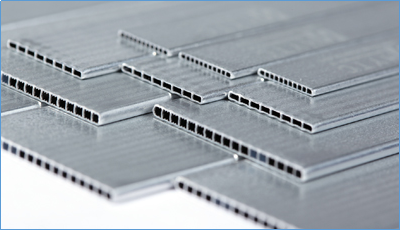

- Furnace linings: Furnace linings protect the furnace from the heat and corrosive effects of the materials being processed. Alumina ceramic fiber textiles are an excellent choice for this application because they are lightweight, flexible, and fire-resistant. They are also able to withstand thermal shock, which is a sudden change in temperature that can cause other materials to crack or shatter.

- Aerospace applications: Alumina ceramic fiber textiles are used in a variety of aerospace applications, such as aircraft wire insulation and engine firewalls. These applications require materials that can withstand high temperatures and flames. Alumina ceramic fiber textiles are ideal for these applications because they are lightweight, flexible, and fire-resistant. They are also able to withstand the harsh environments found in aircraft, such as the extreme heat and cold of high altitudes.

- Solid Oxide Fuel Cell (SOFC) generators: SOFC generators are used to convert fuel into electricity. They operate at temperatures up to 1,000°C. The components of these generators must be able to withstand these high temperatures and corrosive environments. Alumina ceramic fiber textiles are ideal for this application because they offer excellent thermal and electrical insulation, as well as good mechanical properties. They are also able to withstand the thermal shock that occurs when SOFC generators are started and stopped.

Conclusion

Alumina ceramic fiber textiles are high-performance materials that can be used in a variety of demanding applications. They offer a unique combination of properties that make them ideal for high-temperature sealing and thermal shielding. As the demand for high-temperature materials continues to grow, alumina ceramic fiber textiles are expected to play an increasingly important role in a variety of industries. If you are looking for an alumina fiber products manufacturer, CHAL is a good choice to you.