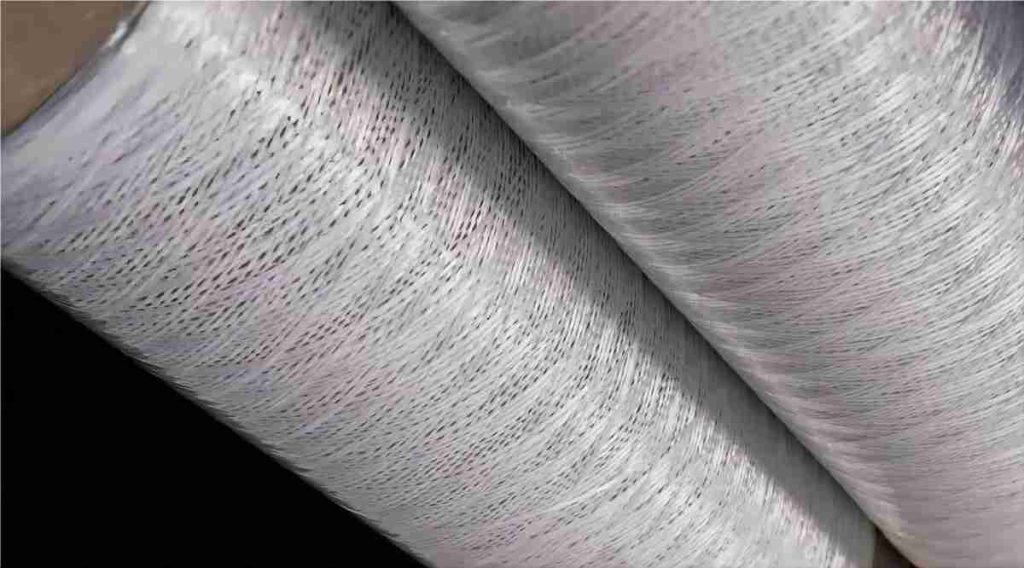

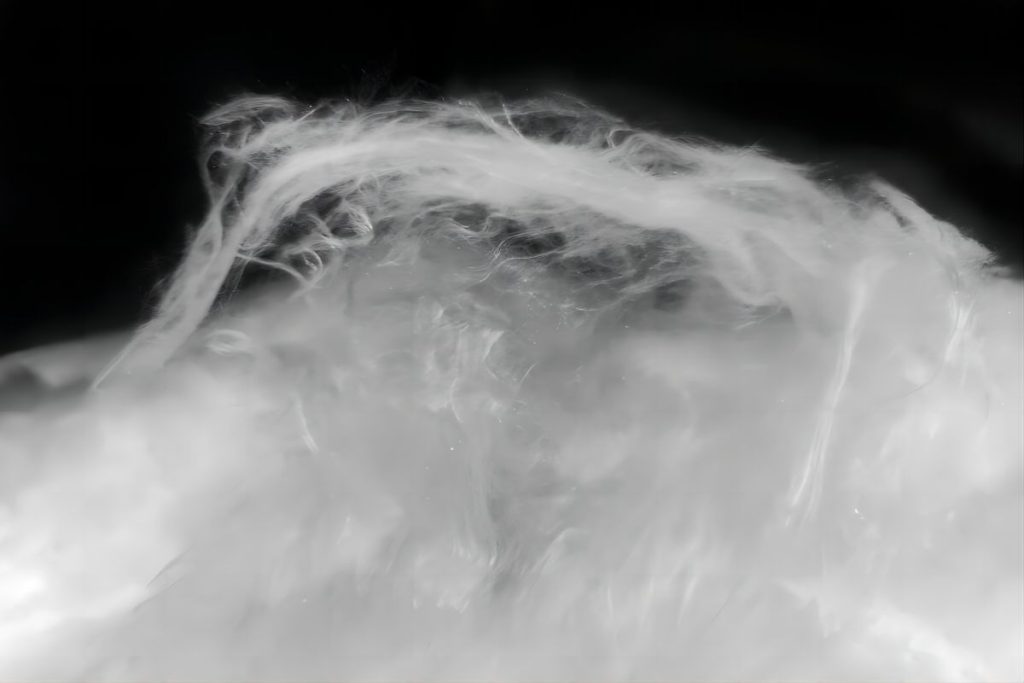

Alumina fiber, also known as aluminum oxide fiber, is a high-performance inorganic fiber with exceptional properties that make it suitable for a wide range of applications. Its main component is aluminum oxide (Al2O3), with trace amounts of other oxides such as SiO2 and MgO. Alumina fiber is known for its remarkable heat resistance, low thermal conductivity, excellent chemical stability, and high electrical insulation. In this comprehensive guide, we will delve into the world of alumina fiber, exploring its melting point, diverse applications, suppliers, pricing, and safety considerations.

Unveiling the Melting Point of Alumina Fiber

Alumina fiber boasts an exceptionally high melting point of 2,024°C (3,673°F), far exceeding the melting points of many commonly used materials. This exceptional characteristic makes alumina fiber an ideal choice for applications that demand high-temperature resistance. It can withstand continuous temperatures of up to 1,300°C (2,372°F) without compromising its structural integrity or performance. This remarkable heat resistance makes alumina fiber suitable for applications in furnaces, kilns, and other high-temperature environments.

Unveiling the Diverse Applications of Alumina Fiber

Alumina fiber’s high melting point and other desirable properties have led to its widespread adoption across various industries. Here’s a glimpse into the diverse applications of alumina fiber:

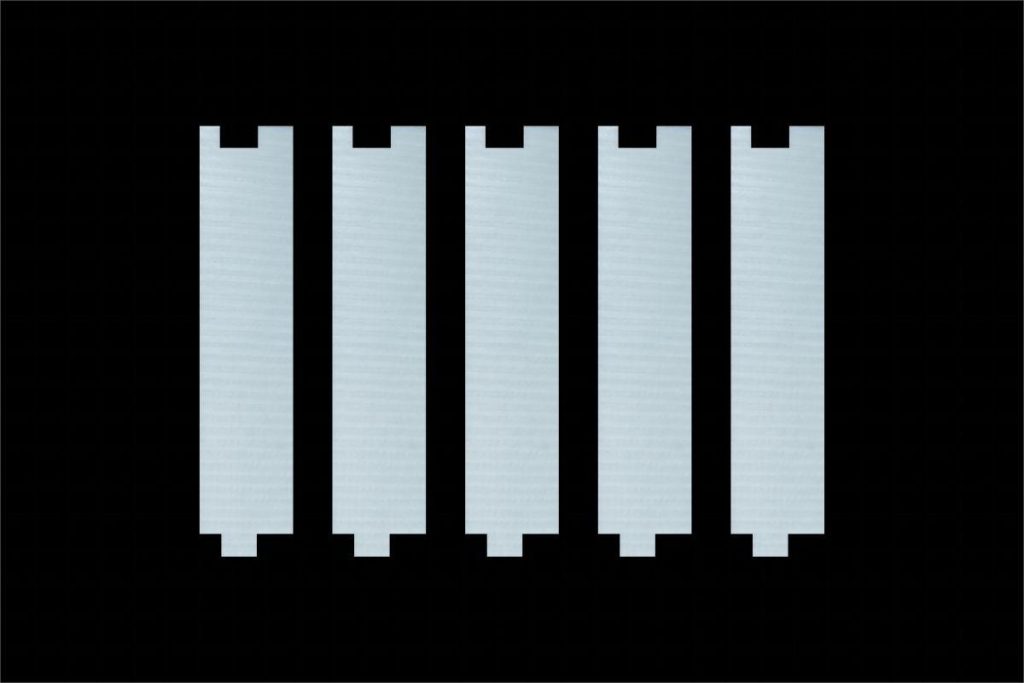

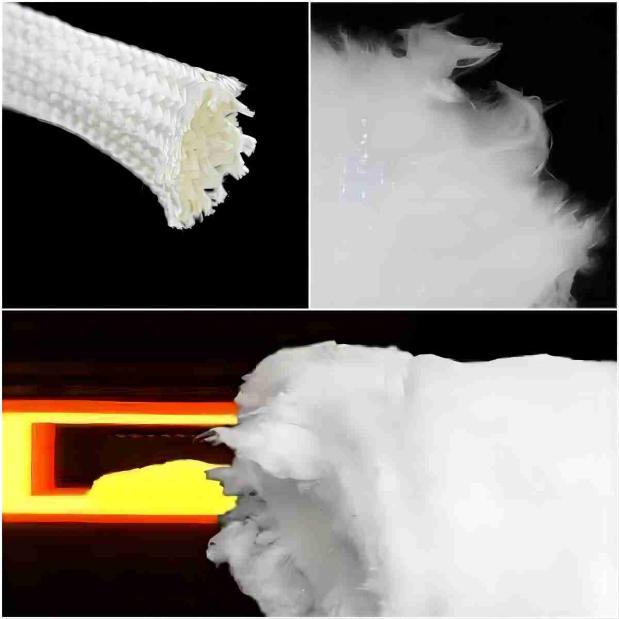

- Thermal Insulation: Alumina fiber’s exceptional thermal insulation properties make it a preferred material for insulating furnaces, kilns, and other high-temperature equipment. Its low thermal conductivity effectively prevents heat loss, contributing to energy efficiency and cost savings.

- Filtration: Alumina fiber’s high porosity and chemical resistance make it an excellent filtration medium for various applications. It effectively removes contaminants from gases and liquids, particularly in industries like chemical processing, pharmaceuticals, and aerospace.

- Ablation: Alumina fiber’s ability to withstand high temperatures and dissipate heat makes it crucial in ablation applications. Ablation refers to the controlled removal of material to protect surfaces from intense heat, such as in spacecraft reentry systems and rocket nozzles.

- Electrical Insulation: Alumina fiber possesses excellent electrical insulation properties, making it suitable for applications involving high voltages and extreme temperatures. It is used in electrical cables, transformers, and other electrical components.

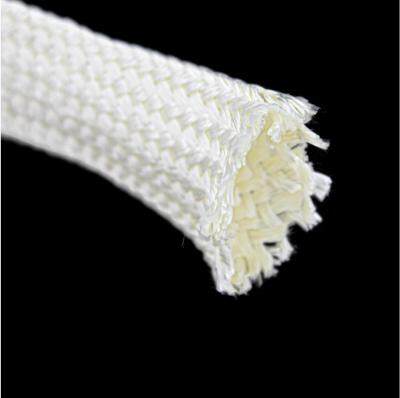

- Reinforcement: Alumina fiber’s high strength and resilience make it an effective reinforcement material for composites. It is used in various applications, including aerospace components, refractory linings, and high-performance textiles.

Where to Buy Alumina Fiber?

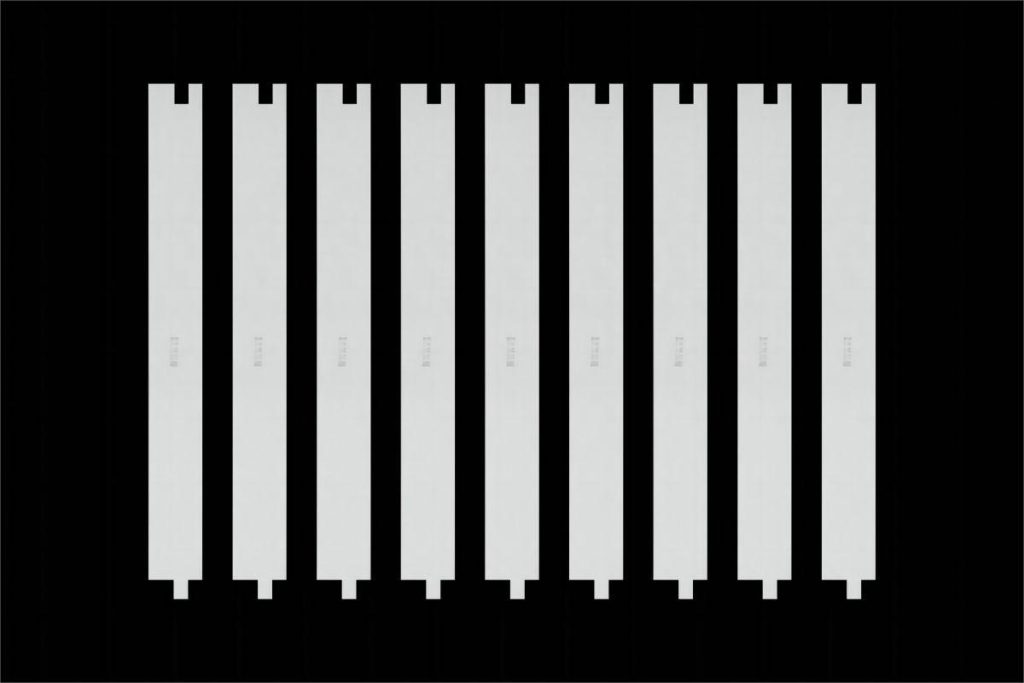

Alumina fiber is widely available from a diverse range of suppliers and manufacturers across the globe. CHAL Aluminium Corporation, a renowned supplier of high-quality alumina fiber products, offers a comprehensive selection of alumina fiber in various forms, including blankets, papers, ropes, tapes, and specialized products tailored for specific applications. CHAL’s commitment to quality and customer satisfaction ensures that users receive the highest-grade alumina fiber products to meet their specific needs.

Apart from CHAL, numerous online retailers and distributors offer alumina fiber in various quantities, catering to both small-scale requirements and bulk orders. These platforms often provide detailed product specifications, pricing information, and convenient shipping options.

Navigating the Cost of Alumina Fiber

The cost of alumina fiber varies depending on several factors, including purity, grade, quantity, and desired form. However, as a general range, alumina fiber can be expected to cost between $10 and $50 per pound.

Factors that influence the price of alumina fiber include:

- Purity: Higher purity alumina fiber commands a higher price due to the additional processing steps involved.

- Grade: Alumina fiber is available in various grades, with higher grades offering enhanced properties, such as improved thermal resistance or chemical resistance, resulting in a higher price.

- Quantity: Larger volume purchases often qualify for discounted pricing due to economies of scale.

- Desired Form: Alumina fiber is available in various forms, such as blankets, papers, ropes, and tapes. Each form has unique processing requirements, influencing the overall cost.

Ensuring Safety in Handling Alumina Fiber

While alumina fiber is generally considered safe when handled properly, it is essential to follow appropriate safety precautions to minimize any potential risks. Here are some key safety considerations:

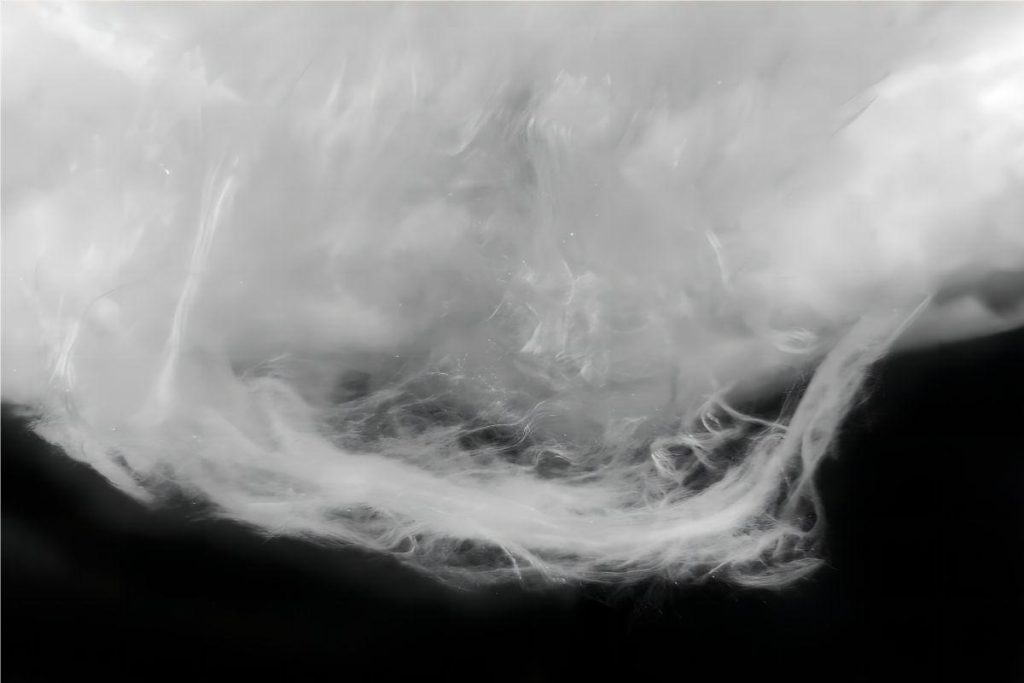

- Inhalation Hazards: Alumina fiber is an inhalable substance, and exposure to excessive amounts can cause respiratory irritation. Wear appropriate respiratory protection, such as a NIOSH-approved dust mask, when handling alumina fiber or working in areas with airborne alumina fiber particles.

- Skin Irritation: Alumina fiber can cause skin irritation in some individuals. Wear protective gloves and clothing to minimize skin contact with alumina fiber.

- Eye Irritation: Alumina fiber particles can cause eye irritation if they come into contact with the eyes. Wear protective goggles or safety glasses when handling alumina fiber.

- Proper Handling Techniques: Handle alumina fiber with care to minimize the generation of airborne particles. Use appropriate tools and techniques, such as wet methods or enclosed systems, to reduce dust exposure.

- Workplace Ventilation: Ensure adequate ventilation in the workplace to minimize the accumulation of airborne alumina fiber particles. Proper ventilation can be achieved through natural airflow or mechanical ventilation systems.

- Cleaning and Disposal: Proper cleaning and disposal of alumina fiber waste is crucial to prevent environmental contamination. Follow the manufacturer’s instructions for cleaning and disposing of alumina fiber waste.

- Personal Protective Equipment (PPE): Always wear appropriate PPE when handling alumina fiber, including respiratory protection, gloves, goggles, and protective clothing.

- Training and Awareness: Provide adequate training and awareness to workers handling alumina fiber about the potential hazards and proper handling procedures.

- Regular Monitoring: Regularly monitor workplace conditions and employee health to ensure compliance with safety regulations and identify potential issues early on.

By adhering to these safety considerations, users can effectively mitigate the risks associated with handling alumina fiber and ensure a safe and productive work environment.

Conclusion

Alumina fiber emerges as a remarkable material with exceptional properties that make it a valuable asset in various industries. Its high melting point, chemical stability, and electrical insulation capabilities have led to its widespread adoption in applications ranging from thermal insulation to filtration systems. With careful handling practices and proper disposal methods, alumina fiber can be safely utilized to enhance performance and efficiency in a wide range of applications.