5052 Aluminum Coil

- The 5052 aluminium coil is an alloy made up of 2.5 percent magnesium and 0.25 percent chromium. It’s considered to have great workability and weldability. It has medium static and high fatigue strength. The corrosion resistance of this aluminum is very good, especially in marine environments. This metal has excellent thermal conductivity and low density, like with other aluminium alloys. To harden aluminum 5052, cold working can be used. Heat treatment cannot be used to obtain higher alloy strength.

- The fatigue properties of this aluminum are excellent, with a limit of 115 MPa while in the H32 temper and 123 MPa while in H34 temper. Compared to the other aluminum alloys, the 5052 grade of aluminum has midway alloying content and strength. In slightly alkaline environments, 5052 alloys show a resistance level. Its resistance to marine environments is better than that of 5005 alloys, making it a more popular choice for marine applications.

Chemical Composition of 5052 Aluminum Coil

| Elements | Si | Cu | Mg | Zn | Mn | Cr | Fe | Other | Al |

| Contents | 0.25 | 0.1 | 2.2-2.8 | 0.10 | 0.10 | 0.15-0.35 | 0.4 | 0.15 | rests |

Specifications of 5052 Aluminum Coil

| Temper | F, O, H14, H16, H18, H19, H22, H24, H26, H28 |

| Thickness (mm) | 0.014-8 |

| Width (mm) | 40-2600 |

| Length (mm) | Customized |

| Typical applications | Silo, flange material, GIS shellAutomobileBus trunk board marine, petrochemical equipment, and components |

Application of 5052 Aluminum Coil

Aluminum sheet plate 5052 is used in many types of industrial applications, including:

- Refrigerator liners

- Fuel tanks

- Storm shutters

- Panels

- And more

The 5052 aluminum coil is widely used in automobiles. It is commonly used in covers and parts, truck shock absorbers, etc., for example, the side panels of semi-trailers produced in the United States and the 5052 aluminum alloy with inner thicknesses of 4-5 mm.

The 5052 aluminum coil is also widely used in ships. The construction and working environment of the ship require that the material should have good corrosion resistance, weldability, plasticity, and certain tensile strength, yield strength, elongation, impact resistance, and other properties. 5052 aluminum alloy can meet these properties, and it can be used in ship construction, such as a deck, ship side, bottom plate, wheelhouse, porthole, mast, and so on.

5052 is also an aluminum alloy for can lids, beer with internal pressure, carbonated beverage cans, and juice cans without internal pressure, respectively, with 5082 aluminum alloy and 5052 aluminum plate, the materials are first oxidized to improve the adhesion and corrosion resistance of the coating. After the two sides are painted and dried, the can lid is processed.

Performance Advantages of 5052 Aluminum Coil

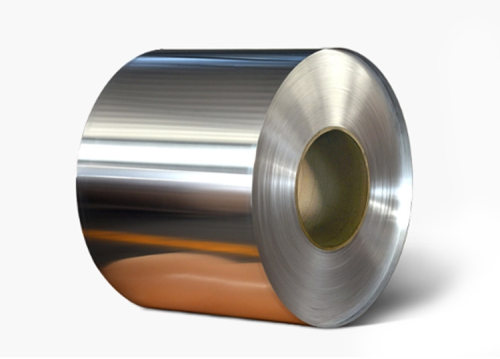

- The surface is smooth, with no cracks, corrosion spots, and traces of nitrate;

- High fatigue resistance, good plasticity, and corrosion resistance;

- Good weldability, poor machinability, polishing;

- 5052 aluminum coil elongation can reach 12-20%, then the 1060 aluminium plate elongation increased by 200%.

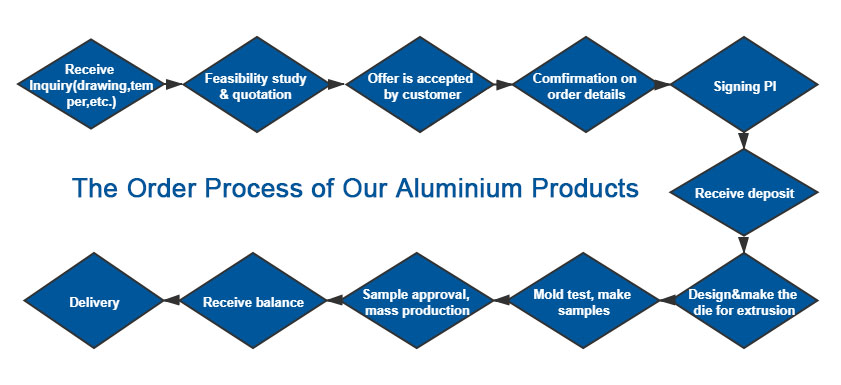

The Order Process of 5052 Aluminium Coil

Packing of 5052 Aluminum Coil