Aluminum Magnesium Manganese Metal Roof Series

What is Aluminum Magnesium Manganese Plate?

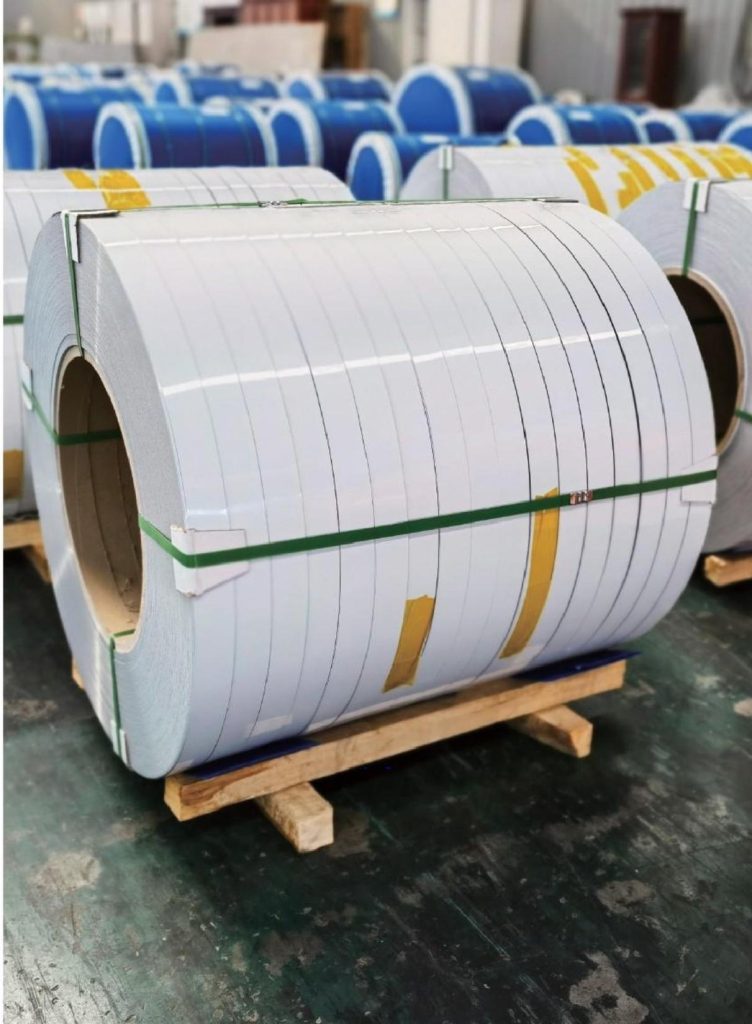

The main component of the aluminum-magnesium-manganese plate is aluminum, and a small amount of magnesium, manganese, and other alloy components are added. According to the different proportions of various metal roofs in the aluminum alloy, 9 series of aluminum alloy plates are formed. The density of aluminum is 2.73g/cm, which is about 1/3 of steel. Therefore, compared with color steel,aluminum-magnesium-manganese alloy plates are lighter in weight. The thickness 0.7MM-1.2MM, is widely used on aluminum magnesium manganese plate.

Applications of Aluminum Magnesium Manganese Plates

Aluminum-magnesium-manganese plates are easy to produce, process, and form, durable and recyclable, and are often used in different building types:

- Small roofs such as villas, residential areas, and sales departments use short-standing side-locking aluminum-magnesium-manganese versions, which are fresh, beautiful, and delicate.

- The flat lock system, named for its interlocking metal plates, is usually used on walls and roofs with a slope exceeding 60 degrees, including rectangular plates, rhombus plates, hexagonal plates, etc.

- Automobile 4S shops often use aluminum-magnesium-manganese horizontal wave boards,etc.,to express different aesthetics.

What is an Aluminum Magnesium Manganese Metal Roof?

Multifunctional aluminum-magnesium-manganese roof panel structure layer: standing lock seam aluminum-magnesium-manganese roof plate, insulation cotton moisture-proof membrane structure, bottom plate punched sound-absorbing plate. The upper layer of the roof is also capable of installing various multi-functional layers, such as windproof fixtures, snow shields, aluminum veneers, photovoltaic power generation, etc., to meet the needs of different climates and environments, and has rich application potential.

Advantages of Metal Roofing System

- Lightweight, the density of aluminum is 2.73g/cm3, only 1/3 of steel;

- High strength and corrosion resistance;

- Various surface treatments, beautiful appearance, good plasticity, and easy processing;

- Good electrical conductivity and easy installation;

- Environmental protection,100%recyclable.

Products Category of Aluminum Magnesium Manganese Metal Roof Series

1. Standing Seam Metal Roof Series

The most commonly used aluminum-magnesium-manganese standing seam for large roofs is made of T-shaped aluminum alloy. This fixing method belongs to the floating design concept, that is, the roof panel can slide freely on the fixed support, completely eliminating the influence of metal thermal expansion and cold contraction. At the same time, this fixing method makes the whole system not have a single screw to penetrate the roof, making the roof waterproof,wind-resistant, and corrosion-resistant.No need for chemical caulking, free from pollution and aging problems. Three-dimensional arc-specific modeling is easy to do. The lightning protection characteristics are also excellent. The construction is safe, fast, and accurate.

Performance Parameters:

- System style: thick lines, flexible detail design, diverse architectural styles

- Commonly used materials: aluminum magnesium manganese plate

- Applicable shape: convex arc, concave arc, taper, and other irregular shapes

- Applicable buildings: airports, stations, swimming pools, theaters, museums, libraries, gymnasium buildings and other public buildings

- Height: 65MM

- Common width:330MM, 400MM, 430MM, 460MM, 470MM, 500MM

- Common thickness: 0.7MM, 0.8MM, 0.9MM, 1.0MM, 1.2MM

- Applicable slope: 10°(increase the slope in heavy snow laden land)

- Advantages: flexible laying method, good forming ability, good three-dimensional vertical edge effect.

2. Metal Roof Vertical Edge Double Bite Series

Performance Parameters:

- System style: beautiful lines, flexible detail design, diverse architectural styles

- Commonly used material: aluminum magnesium manganese plate

- Applicable modeling: convex arc, concave arc, cone, and other irregular shapes

- Applicable buildings: Public architecture such as villas, clubs, libraries, museums, hotels and landscape architecture.

- Height: 25MM, 28MM, 30MM, 32MM, 35MM, 38MM

- Commonly width: 330MM, 400MM, 430MM

- Common thickness: 0.7MM, 0.8MM, 0.9MM, 1.0MM

- Applicable slope gradient: 10°(increased slope in heavy snow)

- Advantages: good waterproof resistance, good molding ability, easy installation.

The Order Process of Aluminum Magnesium Manganese Metal Roof Series