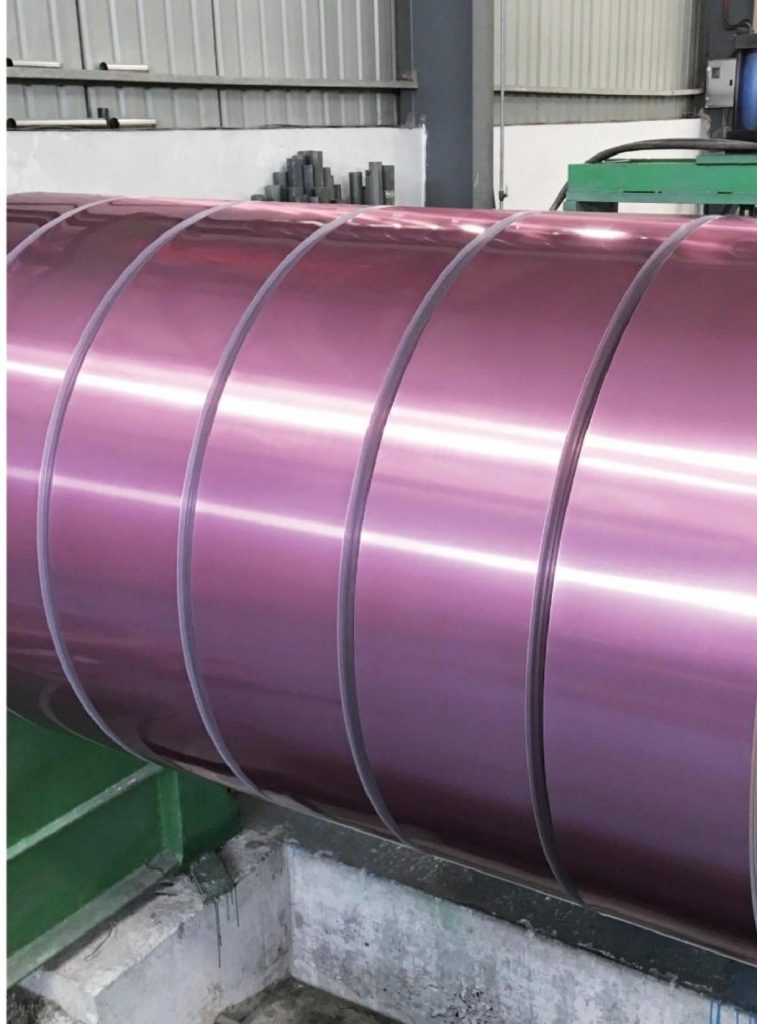

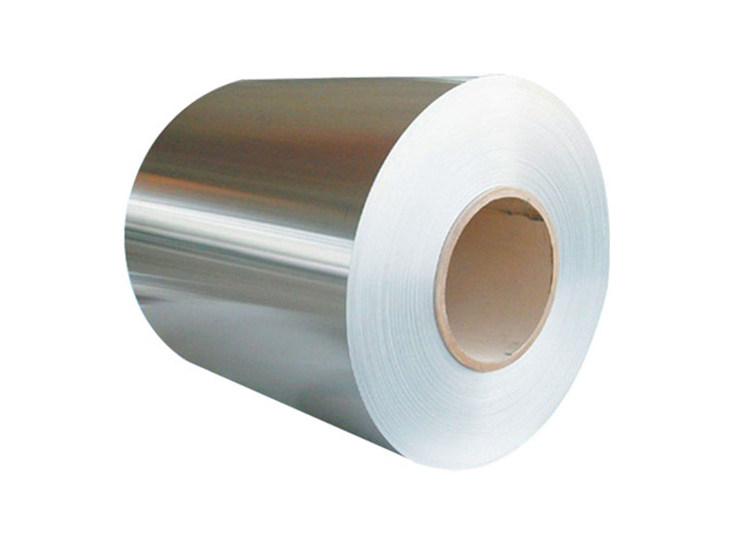

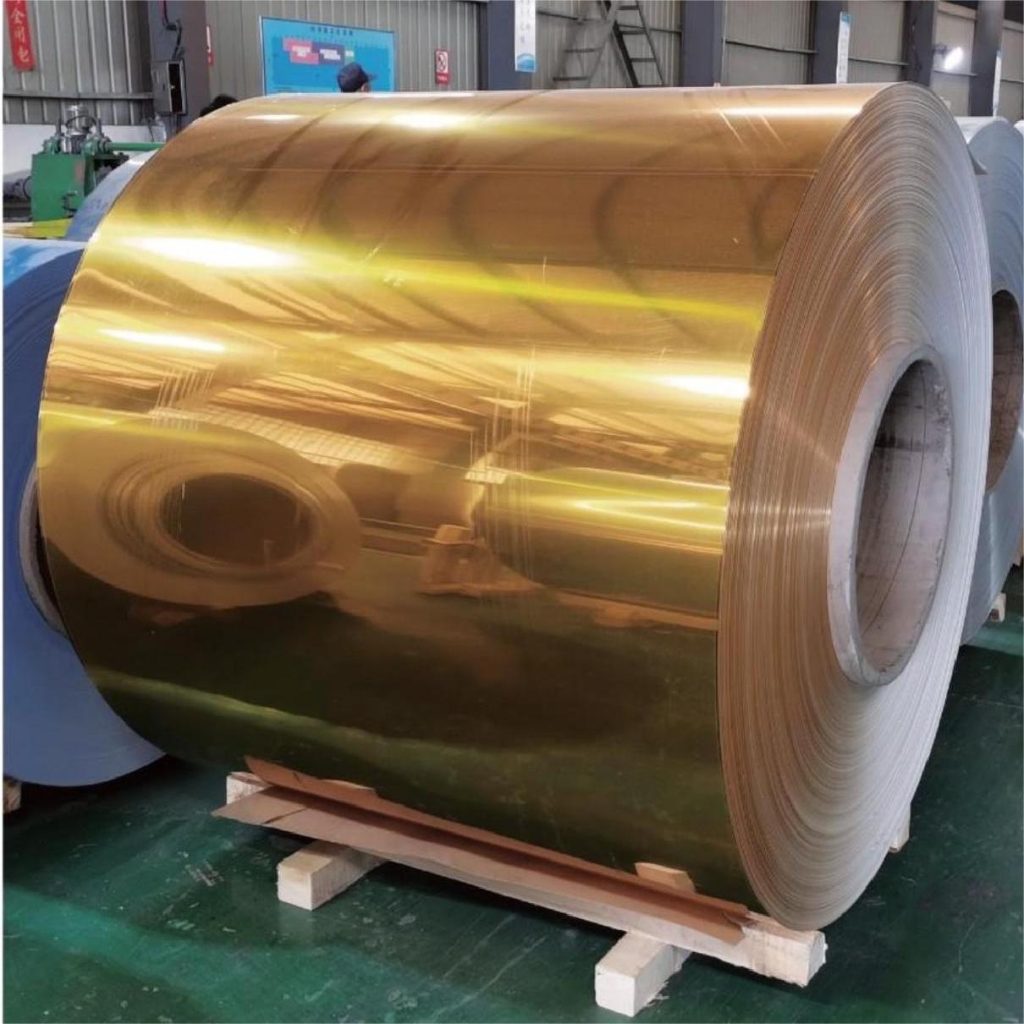

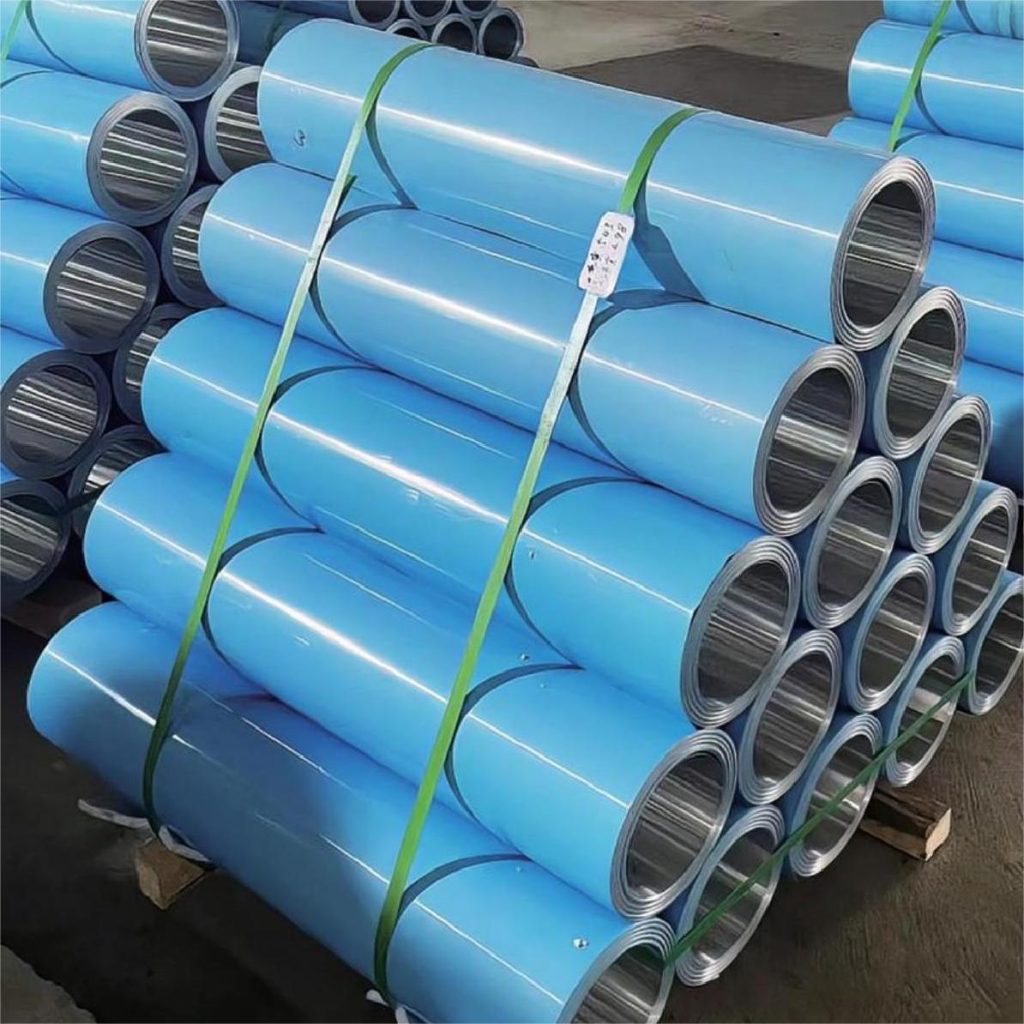

High Durable Color Coated Aluminum Coil

- Dry film thickness front requirements: primer 5 microns, top paint 20-22 microns.

- Recommended on the back: primer 5 microns, back paint 5 microns

- Color: Colors can be customized as customer’s demands. But in order to improve the weather resistance, some colors need to be replaced by similar colors

- Gloss: 35+/- gloss can be provided. We also can provide other gloss according to customer requirements.

Performance Parameters of High Durable Color Coated Aluminum Coil

- Grid adhesion: Paint film does not fall off

- T-bend: 3T paint film without shedding

- Reverse impact: 9J paint film does not fall off

- Pencil hardness: ≥2H (Zhonghua brand 505 roll steel coating hardness test pencil)

- Organic solvent resistance: butanone MEK wipe 100 times, no damage to the film.

- Scratch resistance: The weight of the probe scratch tester is 1800 grams, and the paint film is not broken.

- Humidity and heat resistance: non-condensing humidity and heat test chamber is placed for 1000 hours, no bubbles, cracks, paint film peeling, no color, luster and hardness changes.

- Acid and alkali resistance: 5%hydrochloric acid soaking for 24 hours, no significant changes in appearance. After soaking in 5%sodium oxyoxide for 24 hours, there was no obvious change in appearance

- Boiling water resistance: 100°boiling water bath for 2 hours, no loss of light, discoloration, cracking, foaming, falling off, and other phenomena.

- Acid and alkali resistance: neutral salt spray test 1000 hours, foaming grade <2S3, no other obvious defects

- UV lamp acceleration: OUVA-340 UV lamp test chamber 2000 light hours, powder≤1 level, no blistering, cracking and other defects. (lf assessed according to ASTM D4214 method, pulverization is not less than grade 8)

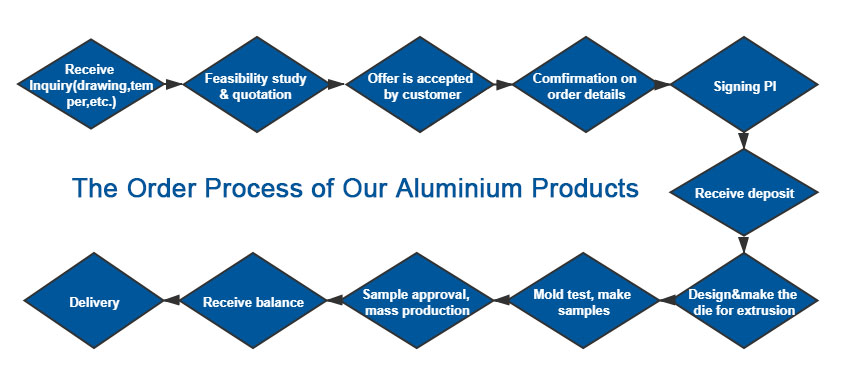

The Order Process of High Durable Color Coated Aluminum Coil