Aluminum Condenser Drier

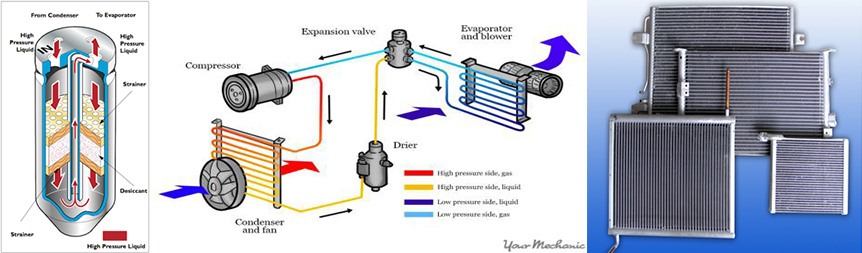

The aluminum condenser drier (also referred to as aluminum receiver drier) looks like small sealed metal cans with an inlet and outlet. They are only used on systems that contain expansion valves.

Aluminum Condenser Drier Introduction

They are comparable to accumulators, although they serve a slightly different function. An aluminum condenser drier differs from an accumulator in these two ways:

- It is considerably smaller than an accumulator, usually around half the volume.

- They are always located on the high-pressure side of the system, usually between the condenser outlet and the expansion valve inlet.

We provide two types of drier: an add-on type aluminum condenser drier (no need for brazing) and an integrated aluminum condenser drier (brazing with condenser core). We have more than 200 specifications in stock, including aluminum condenser driers for Volkswagen, General Motors, Toyota, Audi, Honda, Hyundai, Ford, Citroen, etc. For more details and catalog, please contact us.

| Aluminium Condenser Drier | |

| Material | Aluminum alloy |

| Specification | As per OEM number or drawing |

| Thickness | Customized |

| Forming process | Impact extrusion, Machining |

| Surface treatment | Cleaned, can be customized |

| Type | Add-on type condenser drier (no need for brazing) and integrated condenser drier |

| Certificate | ISO/IATF 16949; ISO14001:2004 |

| Origin | China |

Application of Aluminum Condenser Drier

They have a wide range of applications for:

- HVAC/ Vehicle/ Air conditioning Condenser

- Condenser drier Volkswagen, General Motors, Toyota, Audi, Honda, Hyundai, Ford, Citroen, etc.

CHAL auto parts are manufactured with stringent factory standards to provide new-car performance and efficiency. Aluminium receiver drier is used with a parallel flow car condenser, and it is an important component of the air-conditioning system. We introduced new technology from Japan and Germany, which uses advanced expanding technology on the port, sealed with aluminum nut and snap rings.

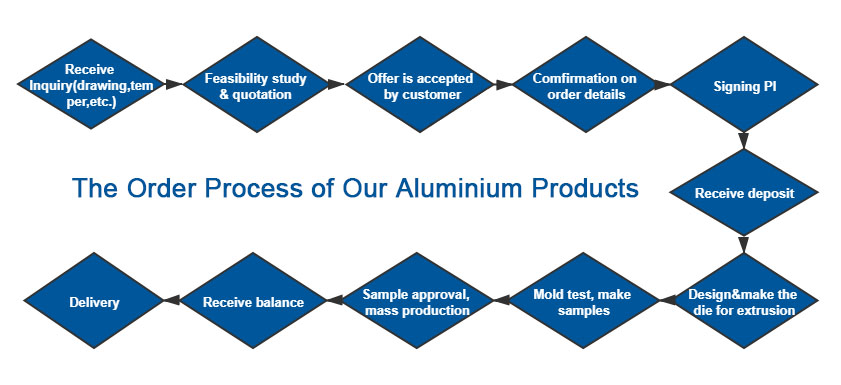

Order Process of Aluminum Condenser Drier

Why Choose Us For Aluminum Condenser Drier?

CHAL Aluminium Group is committed to providing innovative aluminum solutions with higher performance, quality, and value fabrication services. CHAL has its own auto parts division, which specializes in manufacturing a new model of aluminum condenser drier, also called aluminum drying bottle, super-cooled liquid storage tank. CHAL auto parts are manufactured with stringent factory standards to provide new-car performance and efficiency. Aluminum receiver drier is used with a parallel flow car condenser, and it is an important component of the air-conditioning system. We introduced new technology from Japan and Germany, which uses advanced expanding technology on the port, sealed with aluminum nut and snap rings. Our company researches and develops high technology of the bottom seal. It is cost-effective, environment-friendly, easy to fitting and it has a good appearance. Meanwhile, it gets good quality, has no risk of leaking, and burst pressure is above 10.5Mpa. The quality has been highly recognized by OEM customers and aftermarket.

We provide aluminum condenser drier with excellent service

- Provide OEM and customized service.

- Professional engineers team.

- Prompt reply (reply and offer the price in 24 hours)

- High quality & Competitive price

- Timely delivery & Best service

International shipping around the world

All the aluminum condenser driers can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

What are aluminum condenser driers?

The aluminum condenser drier’s primary function is to receive and store some liquid refrigerant from the condenser. The liquid refrigerant enters at the top of the receiver and falls to the bottom. A pickup tube with a filter screen extends to the bottom of the receiver-drier. This pickup tube draws the liquid refrigerant from the bottom of the aluminum condenser drier. The liquid refrigerant then passes on to the inlet of the thermostatic expansion valve.

Also, like an accumulator, an aluminum condenser drier serves as a temporary storage container for oil and refrigerant when not needed for system operation, such as during periods of low cooling demand. The aluminum condenser drier also contains the system desiccant. This is the “drier” function of the aluminum condenser drier.

When having your mobile A/C system professionally serviced, insist on proper repair procedures and quality replacement parts. Insist on recovery and recycling so that refrigerant can be reused and not released into the atmosphere.

How does the aluminum condenser drier work?

The aluminum condenser drier contains a material called a desiccant. The desiccant is used to absorb moisture (water) that may have gotten inside the A/C system during manufacture, assembly, or service. Moisture can get into the A/C components from humidity in the air. This is their “drier” function of them.

What are the functions of an aluminum condenser drier?

Aluminum condenser driers are always located on the high-pressure side of the system, usually between the condenser outlet and the expansion valve inlet. The primary function of the aluminum condenser drier is to receive and store some liquid refrigerant from the condenser.

The main functions including such as liquid storage, filtration, drying

- Storage: aluminum condenser drier acts as a temporary storage container for oil and refrigerant. This is the “condenser” function of the receiver/drier.

- Filtration: most of them contain a filter that can trap debris that may be inside the A/C system.

- Drying: aluminium condenser drier has a material called a desiccant. The desiccant is used to absorb moisture (water) that may have gotten inside the A/C system during manufacture, assembly, or service. Moisture can get into the A/C components from humidity in the air. This is the “drier” function of the receiver/drier.

- Assures cold A/C temperatures on even the hottest days.

- Promotes smoother, quieter A/C system operation.

- Limits internal corrosion, extending A/C system’s service life.

3 important functions of the aluminum condenser drier in your car’s A/C system

They act as temporary storage containers for oil and refrigerant when neither is needed for system operation (such as during periods of low cooling demand). This is the “condenser” function of them.

Most of them contain a filter that can trap debris that may be inside the A/C system.

They contain a material called a desiccant. The desiccant is used to absorb moisture (water) that may have gotten inside the A/C system during manufacture, assembly or service. Moisture can get into the A/C components from humidity in the air. This is the “drier” function of the aluminum condenser drier.