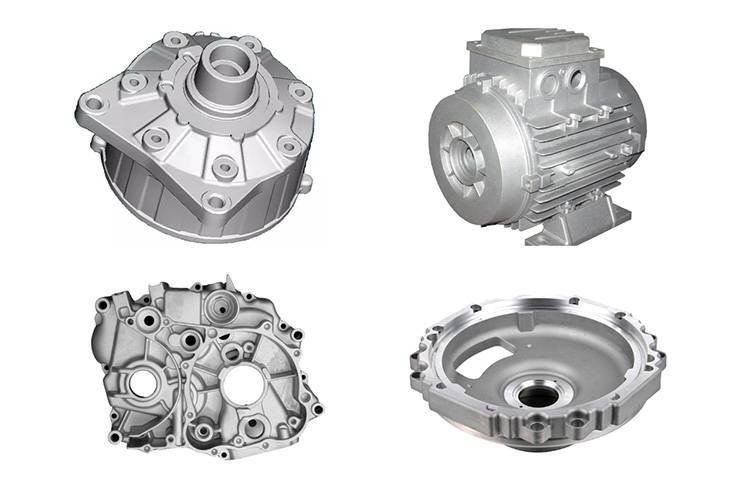

Innovation and technology have transformed the manufacturing industry, providing new solutions for complex problems. The aluminium die-casting industry is no exception, with advances in technology and new materials leading to the development of custom aluminium die-casting parts that offer a wide range of benefits. In this advertorial, we’ll explore the advantages of using custom aluminium die-casting parts and how they can help you achieve your goals.

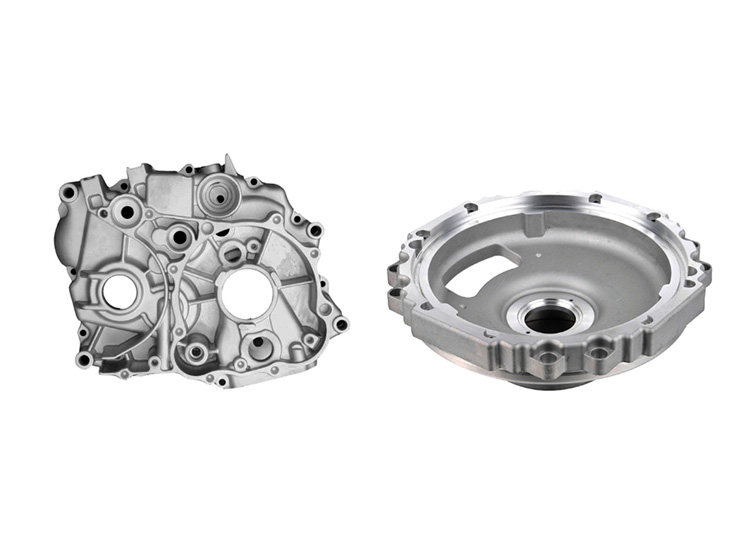

Strength and Durability

Aluminium die-casting parts are known for their strength and durability. They are able to withstand high temperatures, heavy loads, and extreme conditions, making them ideal for a wide range of applications. The high strength-to-weight ratio of aluminium die-casting parts also makes them a popular choice in industries where weight reduction is critical, such as aerospace and automotive. With the right design and material selection, custom aluminium die-casting parts can be optimized for specific applications to maximize their strength and durability.

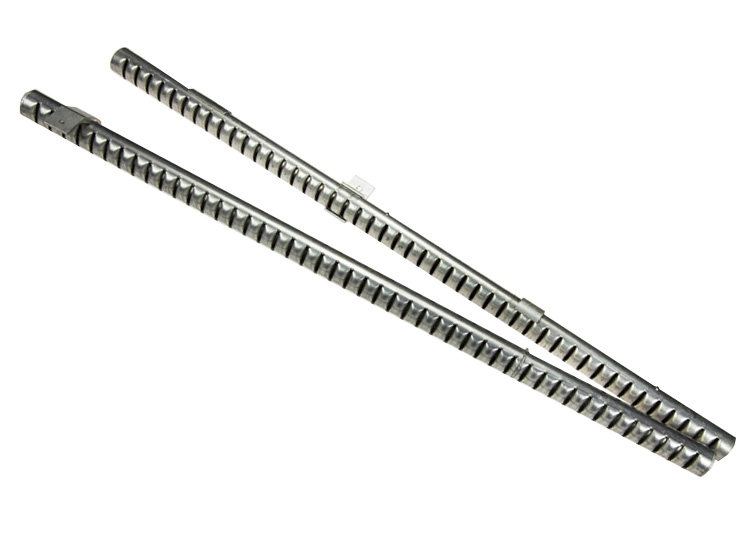

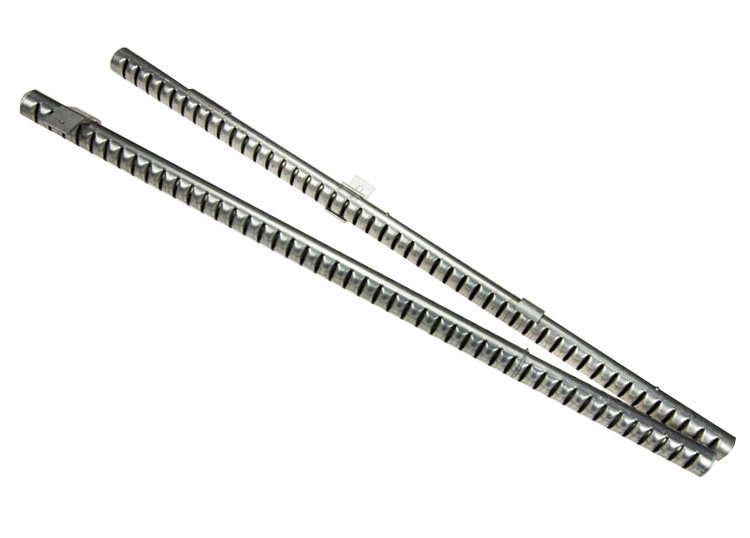

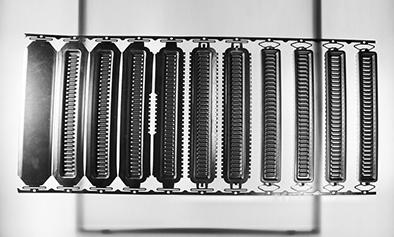

Design Flexibility

One of the key benefits of using custom aluminium die-casting parts is their design flexibility. The die-casting process allows for the creation of complex shapes and sizes, which can be optimized for specific applications. This allows for greater design flexibility and the ability to create parts that are tailored to specific needs. In addition, aluminium die-casting parts can be finished with a wide range of surface treatments, including powder coating and anodizing, to provide additional protection against wear and corrosion.

Cost-Effective

Aluminium die-casting parts are a cost-effective solution for many applications. They can be produced in high volumes with consistent quality, which reduces the cost per part. The speed and efficiency of the manufacturing process also help to reduce lead times and overall production costs. With the right design and material selection, aluminium die-casting parts can provide a cost-effective solution without compromising on quality or performance.

Environmental Benefits

Aluminium die-casting parts also offer environmental benefits. Aluminium is a highly recyclable material, and the die-casting process itself generates very little waste. In addition, using aluminium die-casting parts can help reduce fuel consumption and emissions due to their lightweight nature. This makes them an ideal choice for applications where sustainability is a concern.

Customization and Expertise

Finally, customisation and expertise are key advantages of using custom aluminium die-casting parts. At our company, we work closely with our customers to develop parts that are optimized for their specific applications. Our team of experts has the design expertise necessary to help you develop parts that are optimized for your unique needs. Whether you need parts that are lightweight, durable, or have a specific shape or size, we can help you find the solution that works best for you.

Conclusion

Innovation and technology have transformed the aluminium die-casting industry, making custom parts stronger, more durable, and more cost-effective than ever before. Whether you’re looking to reduce weight, improve performance, optimize design flexibility, or reduce environmental impact, custom aluminium die-casting parts are a great solution. With their strength, durability, design flexibility, cost-effectiveness, and environmental benefits, they’re a popular choice in a wide range of industries. Contact us today to learn more about how we can help you achieve your goals with custom aluminium die-casting parts.