Alumina Continuous Fiber

The emerging high-tech industry, aerospace, new defense weapons, and other advanced technology sectors are in dire need of a diverse range of materials.

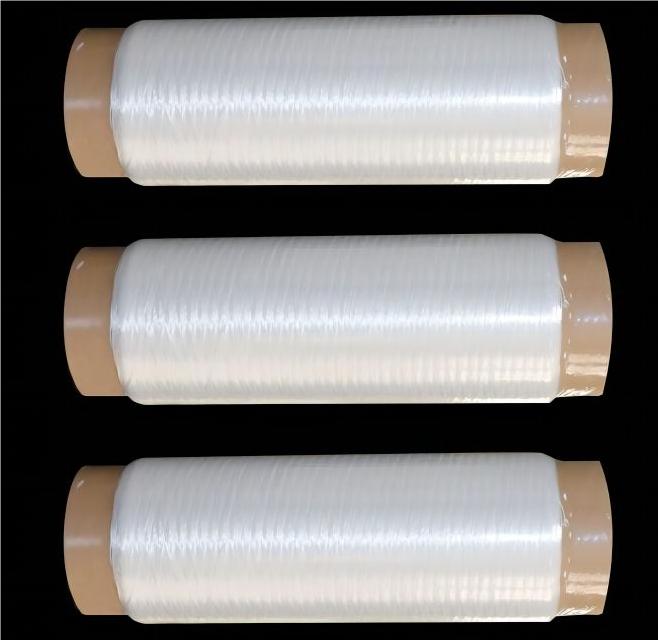

Product Introduction

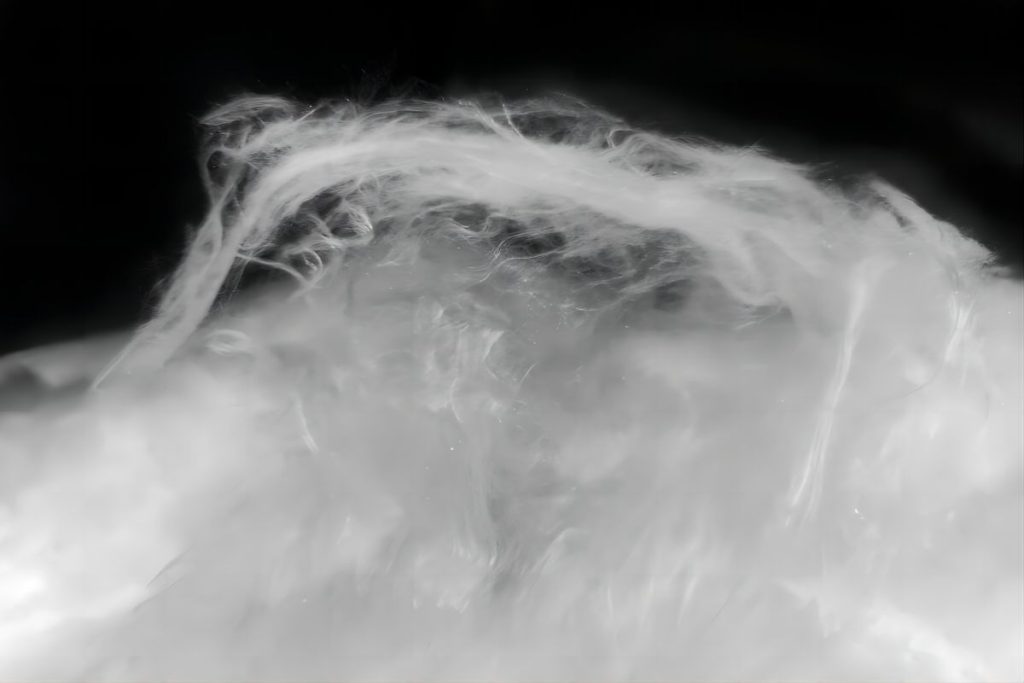

Alumina continuous fiber, formulated primarily with alumina and silica, is produced through the sol-gel process. This remarkable material exhibits exceptional heat resistance, enabling it to withstand prolonged exposure to temperatures exceeding 1000℃. It can be intricately woven into flexible fabrics resembling fiber ropes and cloths. Moreover, it serves as a valuable component for creating various composite materials due to its convenient and adaptable form. As a crucial component in emerging high-tech industries, including aviation, aerospace, and national defense weaponry, the demand for such materials is urgent. Our product range encompasses different models, namely AF17, AF18, and AF19, which vary based on alumina content.

Product Performance

Excellent High and Low Temperature Resistance

The AlO3 fiber exhibits an impressive service temperature capability of up to 1600℃, while the mullite fiber can withstand temperatures up to 1400℃. Additionally, even after being subjected to a 24-hour treatment with liquid nitrogen (-196℃), both fibers retained their strength without any decrease.

Acid and Alkali Resistance

After immersing in a 10% alkali solution for 24 hours, the fiber strength retention rates are as follows: NaOH—40%, KOH—65%, and NH4OH—95%. Similarly, the fiber strength retention rates after soaking in a 10% acid solution for 24 hours are as follows: HCl—96%, H2SO4—95%, HNO3—96%, and H3PO4—95%.

Good Thermal Insulation Performance

The device constructed using alumina continuous fiber exhibits a high surface temperature of 800℃ on the hot side and a lower surface temperature of 278℃ on the cold side. Furthermore, when the hot surface temperature increases to 1000℃, the corresponding cold surface temperature rises to 388℃.

Excellent Electrical Properties and Electrical Insulation

As the temperature rises, the resistance of alumina fibers decreases. Once it surpasses 600℃, the resistance tends to stabilize at a relatively constant level. Moreover, the dielectric constant and dielectric loss of alumina fiber exhibit remarkable stability at high temperatures, making it an ideal choice for high-temperature wave transmission materials.

Excellent Flexibility

Alumina fiber demonstrates excellent flexibility at room temperature, capable of enduring bending up to 1400 times. Even after undergoing high-temperature treatment at 1000°C, it maintains its flexibility, allowing for bending up to 60 times.

Strong Design

Through the manipulation of chemical composition and heat treatment processes, it becomes possible to achieve products with diverse properties that cater to various application requirements.

Technical Parameter

| Performance | AF17 | AF18 | AF19 |

| Chemical composition (wt.%) | 72 Al2O3+28 SiO2 | 85 Al2O3+15 SiO2 | ≥99 Al2O3 |

| Crystalline phase | γ-Al2O3 | α-Al2O3+Mullite | α-Al2O3 |

| Monofilament diameter(μm) | 9-12 | 11-14 | 11-14 |

| Tex (g/km) | 200±20 | 167±10 | 167±10 |

| Moofilamentstrength (MPa) | ≥1600 | ≥1900 | ≥2800 |

| Monofilament tensile modulus (GPa) | ≥160 | ≥240 | ≥330 |

Product Performance Test

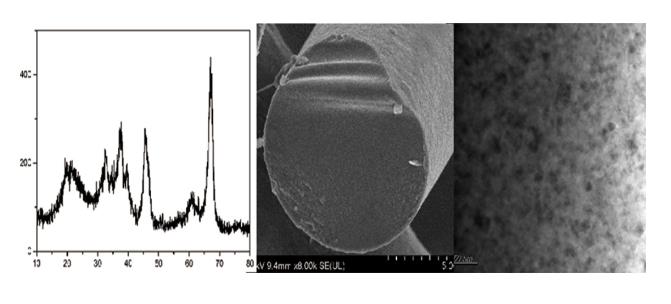

AF17 Fiber

The fiber is composed of microcrystalline polycrystalline (γ-Al2O3) with a diameter ranging from 9 to 12 micrometers. It boasts an impressive tensile strength of over 2.0 GPa at room temperature and can endure service temperatures exceeding 1200℃. Additionally, it exhibits excellent resistance to high temperatures and demonstrates remarkable creep resistance.

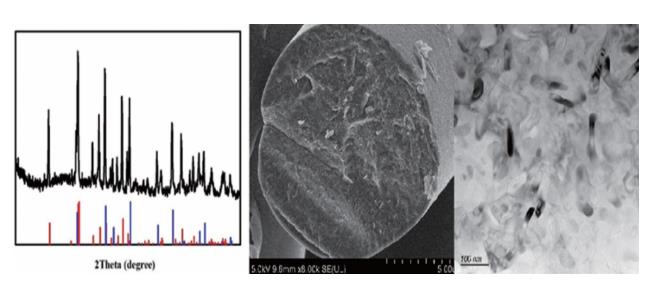

AF18 Fiber

The fiber exists in a microcrystalline state (α-Al203 + mullite), with a diameter ranging from 11 to 14 μm. It demonstrates an exceptional tensile strength exceeding 2.0 GPa at room temperature while being able to withstand service temperatures surpassing 1300°C. Alumina fiber currently exhibits the highest level of resistance against creep deformation. Up to 1100°C, the strength remains relatively unchanged. Even at 1200°C, it retains over 90% of its room temperature strength, and at 1300°C, it retains more than 80% of its room temperature strength.

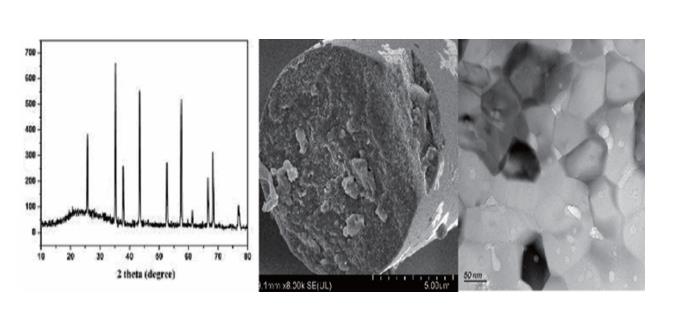

AF19 Fiber

The fiber is characterized by a microcrystalline state (α-Al203) with a diameter ranging from 11 to 14 μm. It exhibits an impressive tensile strength exceeding 3.0 GPa at room temperature and is capable of withstanding service temperatures exceeding 1000℃. With its high strength and favorable mechanical properties, it serves as an excellent reinforcement material for composites. However, it should be noted that the fiber’s creep resistance at high temperatures is relatively poor.

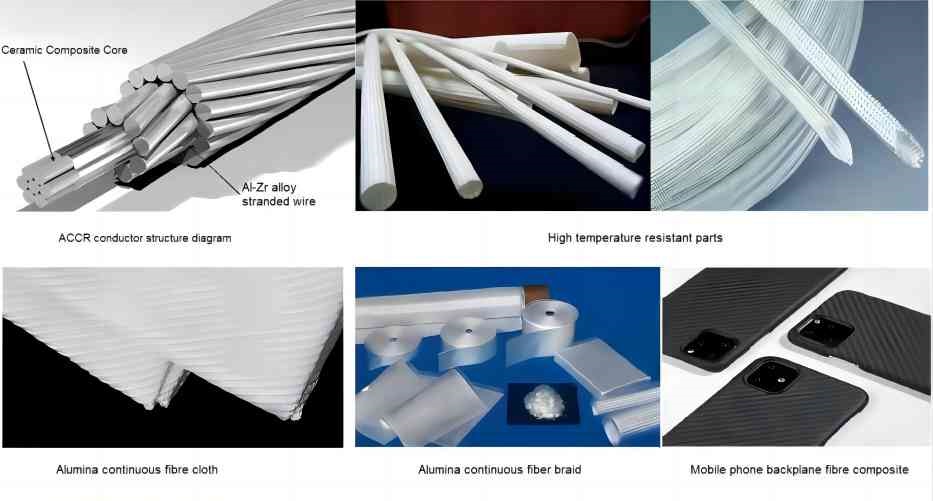

Typical Applications

Aerospace

- Alumina continuous fiber finds its applications in hypersonic aircraft, radomes, and radar radomes. It has emerged as a promising material for fulfilling the elevated temperature demands of next-generation technologies. European and American countries have already incorporated this material into space shuttles, starships, and various weapons and equipment, where it excels in temperature resistance and heat insulation properties.

- Alumina continuous fiber ceramic matrix composites possess exceptional high-temperature strength, making them suitable for various critical applications. They can be employed in insulation layers, nozzle outlet cones, and other related components of rocket motor combustion chambers. Furthermore, they serve as an ideal material for thermal structure insulation connections between nozzles and combustion chambers in solid motors. Additionally, these composites find utility in the hot end components of aviation turbojet engines.

- Aluminum oxide continuous fiber reinforced metal matrix composites are employed in mechanical parts that bear high loads and operate under high temperatures, as well as in high-speed rotating components like transmission devices in helicopters. Furthermore, these composites find application in solid rocket motor nozzles.

- Alumina continuous fiber reinforced light alloy finds valuable applications in the military industry. It serves as an ideal material for pistons in armored vehicles and tank engines, providing enhanced strength and performance. The U.S. Army utilizes continuous alumina fiber reinforced composites to manufacture tank track shoes, resulting in a significant weight reduction from 544 kg of cast steel to 272-363 kg. Moreover, these composites can be utilized for the fabrication of solid motor shells for air-launched missiles. They possess comparable bursting pressure to steel while being 11% lighter than aluminum alloy, offering a favorable balance between strength and weight.

Industrial Sector

- ACCR (Aluminum Conductor Composite Reinforced) composite core wire incorporates aluminum oxide continuous fiber (AF19) embedded within an aluminum alloy wire. This unique combination yields mechanical and electrical properties that surpass those of steel cores. The ACCR composite core wire achieves a breaking strength eight times greater than that of conventional aluminum wire, while its weight is merely half that of an equivalent volume of steel core. Moreover, its electrical conductivity significantly exceeds that of steel cores, and its linear expansion rate is less than half that of steel cores.

Consumer Electronics

- In the field of 5G communication, AF19 alumina continuous fiber possesses exceptional attributes such as heat conduction, insulation, and wave transmission. These qualities make it an excellent choice for manufacturing mobile phone backplane materials. It holds significant value in meeting the future demand for ultra-low latency in 5G smartphones, effectively addressing challenges related to temperature rise in wireless areas and signal issues.

Environmental Protection

- The high-temperature thermal insulation material composed of this fiber exhibits excellent braidability, making it suitable for thermal insulation components and three-dimensional braided parts that require connections. It can also be employed as lining insulation material in various high-temperature furnaces, including metallurgical and ceramic sintering furnaces. With its low density, exceptional insulation properties, and minimal heat capacity, this material not only reduces the weight of the furnace body but also enhances temperature control accuracy. As a result, it offers significant energy-saving benefits.

- Alumina continuous fiber serves as an exceptional chemical corrosion resistant material, possessing outstanding resistance against various corrosive agents. It is particularly well-suited for applications requiring high-temperature filtration in pressurized fluidized bed combustion combined cycle (PFBCC) and integrated coal gasification combined cycle (IGCC) power generation technologies.

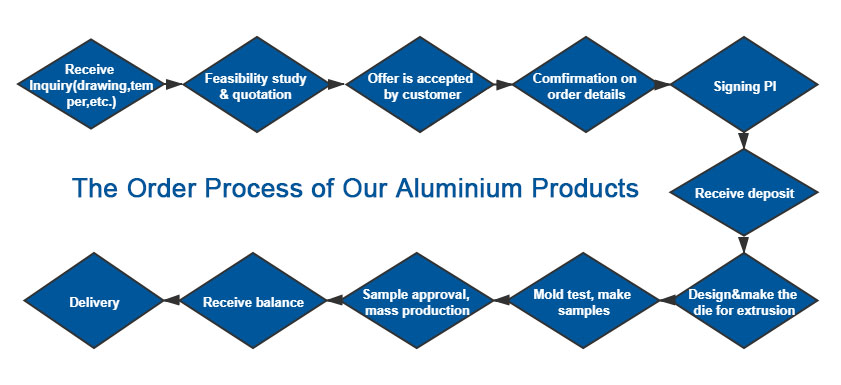

Order Process of Alumina Continuous Fiber