Pharmaceutical Aluminum Foil

- Pharmaceutical aluminum foil is widely used for medicines in the pharmaceutical industry. It consists of a push-through blister, a molded plastic with cavities for the individual tablets, and a push-through closure made of aluminum foil, which is called blister film or lid film.

- The blister pack is formed by placing the medicine in a blister or blister of a plastic molded plastic sheet, and then thermally bonding the plastic sheet to the aluminum foil which is printed and coated with a protective agent and a binder. So aluminum foil for blister packaging is also the main aluminum foil in the field of pharmaceuticals.

- We provide various types of pharmaceutical aluminum foil of different standards for the global market.

Specifications of Pharmaceutical Aluminum Foil

Specifications of bag package of powder particles

| Alloy-Temper | 8079/8079DC/8111-O |

| Thickness (mm) | 0.0065/0.007/0.009/0.012 |

| Width (mm) | 425-1260 |

| Meter (m) | 3000-12000 |

| Core I.D. (mm) | 76 |

| Pinhole (PCs/㎡) | 0.0065≤150 PCs/㎡;0.007≤100 PCs/㎡;0.009≤50 PCs/㎡;0.012≤10 PCs/㎡ |

| Tensile strength (MPa) | 8079DC/8079:0.0065/0.007/0.009/0.012mm:≥80 ; 8111:0.0065/0.007/0.009/0.012mm:≥70 |

| Elongation (%) | 8079DC: 0.0065/0.007mm: ≥2.0; 0.009/0.012mm≥3.0; 8079: 0.0065/0.007/0.009mm≥1.5; 0.012mm≥2.0; 8111: 0.006/0.007/0.009mm≥2.0 |

| Wettability | Atomization A+ |

| Price terms | LC/TT/DA/DP |

| Packaging | Standard seaworthy export packaging. Wooden pallets with plastic protection for the coil and sheet. |

| Appearance | The surface of the foil should be flat and clean, without corrosion, roll marks, abrasion, scratches, dark or bright spots, oil spots, wrinkles, and obvious color differences. Serious ridges, drums, bright lines, stripes, scratches, holes, and other defects affecting the usage are not allowed. |

Benefits of Using Pharmaceutical Aluminum Foil For Pharmaceutical Packaging

The unrivaled barrier properties of aluminum foil make it impenetrable to moisture, aromas, oxygen, and other gases, as well as micro-organisms and light.

Hygienic

Aluminum foil is non-toxic and non-hazardous. It does not harbor or promote bacteria. It can be supplied in a sterile condition. Aluminium foil is also suitable for the application of tamper-evident seals and anti-counterfeiting security, such as holograms.

Sustainable and environmentally friendly

Aluminium foil in pharmaceutical packaging has a very positive environmental profile – it saves weight, reduces transport and handling costs and affords complete protection to sensitive pack contents. Advanced separation techniques allow the aluminum foil in domestic waste to be recovered and recycled at a fraction of the original energy cost.

Versatility

In the medical and personal care markets, aluminum foil is mainly used in push-through blisters as a high-barrier performance, sealable and breakable membrane. In cold-formed blisters or strip packs (e.g. for suppositories), aluminum’s excellent formability allows us to form the material into highly complex shapes without impairing its barrier integrity.

Application of Pharmaceutical Aluminum Foil

- As the shield of PVC hard films for blister packaging, it doesn’t directly contact foods or drugs, suitable for high-density drugs.

- High barrier performance against moisture, oxygen, light, and UV rays.

- Used as special packaging materials for the drugs under extreme (high or low temperature) environments.

- Commonly dominated by gold and silver color, the surface can be beautifully printed for advertising.

- Supporting the use of packaging materials are PTP and PVC.

- The machinery used is a tropical blister packing machine.

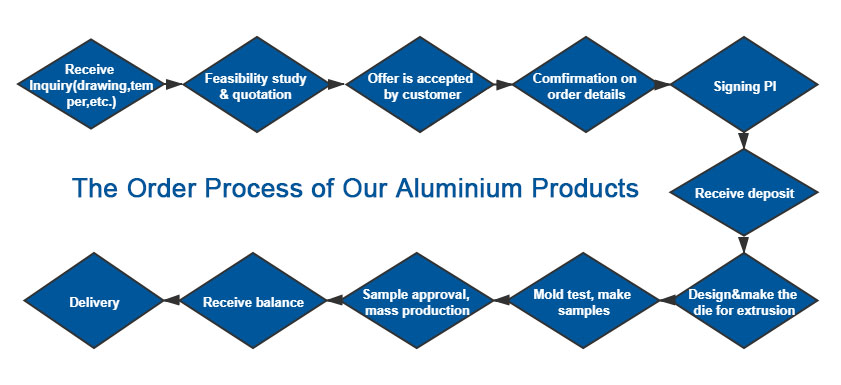

The Order Process of Pharmaceutical Aluminum Foil