Aluminum Clad Foil For Heat Transfer

Aluminum foil can be used for heat transfer material with clad aluminum alloy. CHAL can provide different series of aluminum foils for heat transfer including bare foil, hydrophilic foil, and clad foil.

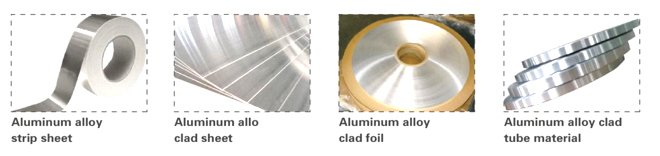

Product Series of Aluminum Clad Foil For Heat Transfer Application

- Bare aluminium alloy foil

- Clad aluminum foil

- Single Side clad foil

- Hydrophilic aluminum foil

- Aluminum clad foil for fin material

- Aluminium clad tube material

- Aluminum clad foil for radiator tube

- Aluminum composite material for heat exchanger

- Aluminum Fin material

- Clad Aluminium Foil for Weld Tube Material

Product Details of Aluminum Foil For Heat Transfer

1. High Strength Aluminum Clad Foil for Radiator Tube Stock Material

Aluminium alloy: 3003(4043/4045/7072)

Thickness: 0.15-0.4mm

Delivery temper: H24

Pre-brazed Tensile strength 190-220MPa

Pre-brazed Yield Strength Min150MPa

Pre-brazed Grain size (core material): Fiber

Post-brazed Tensile strength Min185MPa

Post-brazed Grain size (core material) Min70μm

Post-brazed Electric Potential (core material): -630+/-20mV

Post-brazed Electric Potential (waterside material): -780+/-20mV

Clad brazing material: 10.5+/-2.0%

Waterside material: 17+/-2.5%clad

Application: tube material for heat exchanger tube, radiator tube, intercooler tube

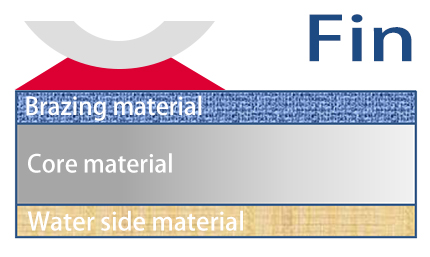

2. High Strength Aluminum Foil for Fin Material

Aluminum alloy: 4343+3003+4343

Thickness: 0.0475-0.08mm+/-0.0025mm

Delivery temper: H14

Pre-brazed Tensile strength: 190-215MPa

Pre-brazed Elongation: Min1.0%(targetMin1.5%)

Pre-brazed Electrical Conductivity Min45%IACS

Post brazed tensile strength>135Mpa

Post-brazed Electrical Conductivity Min41.5%IACS

Post-brazed Grain size Min200μm

Post-brazed Electric Potential -750+/-10mV

Application: air conditioner, condenser

3. High Corrosion Resistance Aluminium Foil for Clad Fin Stock Material

Aluminum alloy: 4343/AA3003/4343 (weight loss%)

Thickness: 0.06-1.2mm

Delivery temper: H16

Post brazing tensile strength>165Mpa

Post brazing yield strength>60Mpa

4. Single Layer Aluminium Foil

Thickness: 0.07/0.08mm

Delivery temper: H16

Post brazing tensile strength>150Mpa

Post brazing yield strength>50Mpa

SWAAT test 4 weeks, performance is 10% better than 4343/AA3003/4343 (weight loss%)

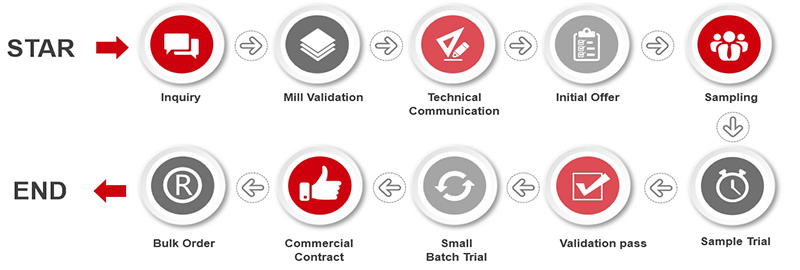

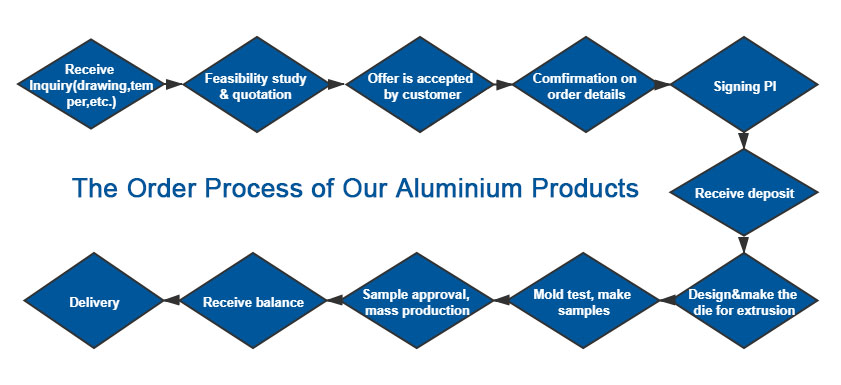

The Order Process of Aluminum Foil For Heat Transfer

Professional Manufacturer of Aluminium Clad Foil For Heat Transfer – CHAL

CHAL Aluminium is a fully integrated aluminium company that provides all kinds of aluminum products and technical solutions. We are committed to being the leading supplier of aluminum plate, aluminum sheet(clad or bare), aluminium foil(clad or bare), aluminum strip(slit coil, aluminium circle, and aluminum foil. Aluminum foil is our key products, we supply a variety of aluminum foil for multitudinous applications, such as aluminum foil for HAVC&R household foil, container foil, label foil, roofing material, and embossing material.

Development Route