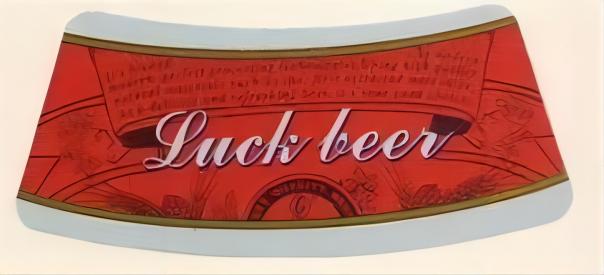

Aluminum Foil Used in Beer Cover Packing

Aluminum foil used in beer cover packing is a kind of foil used for the label on the bottle of beer. The surface of the foil shall be flat and clean, without corrosion, roll marks, abrasion, scratches, dark or bright spots, oil spots, and wrinkles. Serious ridges, drums, bright lines, stripes, bumps, and obvious color differences, and other defects affecting the usage are not allowed. The end surface of the foil shall be neat and smooth, with no obvious color difference, and no defects affecting the opening of the product. Minor burns, bumps, uneven ends, color differences, warping edges, and radial serrations in the range are acceptable.

Aluminum Foil Used in Beer Cover Packing Specification

|

Alloy-Temper |

8011-O |

|

Thickness (mm) |

0.009-0.011 |

|

Width (mm) |

425-750 |

|

Meter (m) |

25000-55000 |

|

Core I.D. (mm) |

150/152 |

|

Pinhole (PCs/㎡) |

0.009≤100PCs/㎡; 0.0091-0.011≤20PCs/㎡ |

|

Tensile strength (MPa) |

90-110 |

|

Elongation (%) |

≥3.0 |

|

Breaking strength (Kpa) |

0.009-0.0095mm:60±15 0.0105-0.011mm:75±15 |

|

Wettability |

Atomization 100% |

|

Appearance |

The surface of the foil should be flat and clean, without corrosion, roll marks, abrasion, scratches, dark or bright spots, oil spots, wrinkles, and obvious color differences. Serious ridges, drums, bright lines, stripes, scratches, holes, and other defects affecting the usage are not allowed. Slight burrs, scratches, color differences, warping edges, and serrated edges in the range are acceptable. |

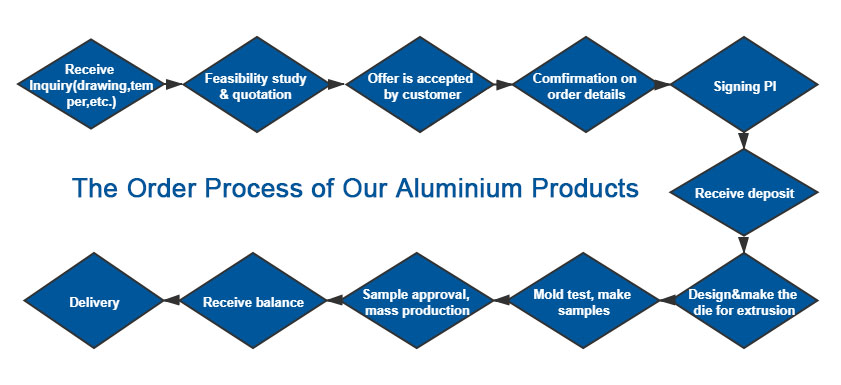

Aluminum Foil Used in Beer Cover Packing Order Process