Aluminium paste, a unique material characterized by its high reflectivity and metallic luster, has found widespread applications across various industries. Composed mainly of aluminum particles and solvents, this versatile pigment is prized for its ability to enhance the aesthetic and functional properties of products. This article delves into the composition, uses, and environmental benefits of aluminium paste, with a particular focus on its application in paints and coatings.

Composition and Structure of Aluminium Paste

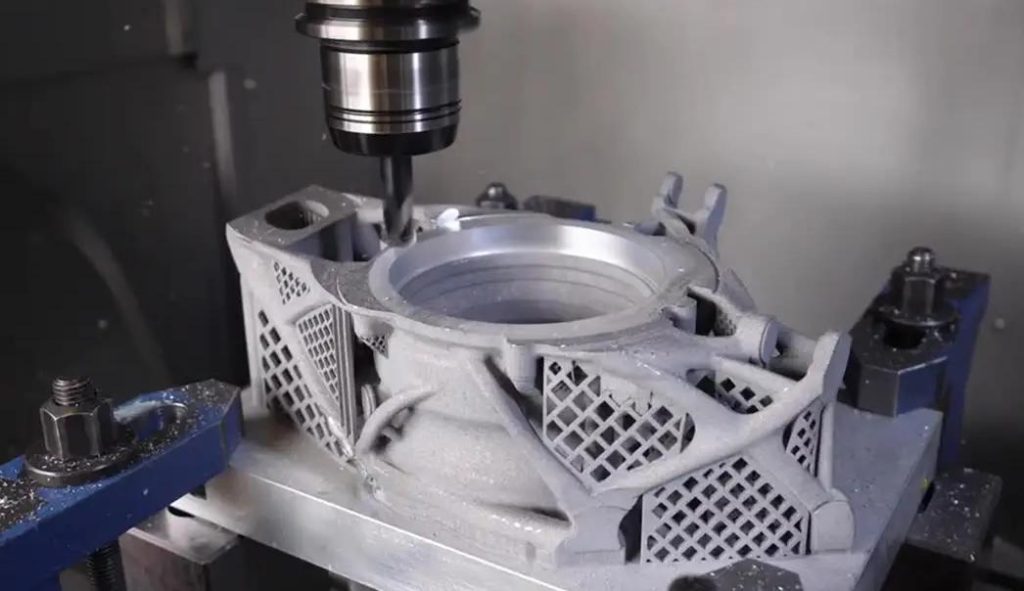

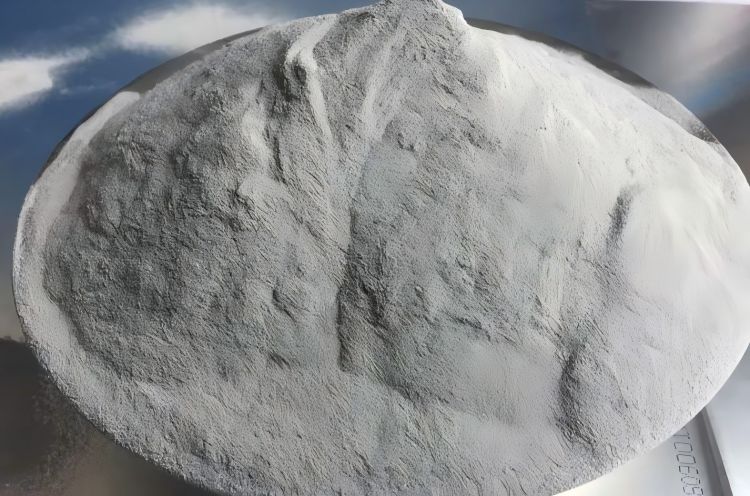

Aluminum paste consists of flake-like aluminum particles suspended in a solvent medium. The flakes are created through a process of milling and grinding aluminum powder until it achieves a desirable size and shape. These flakes can vary in size and thickness, affecting the paste’s final properties. Aluminum paste can be broadly categorized into two types: leafing and non-leafing.

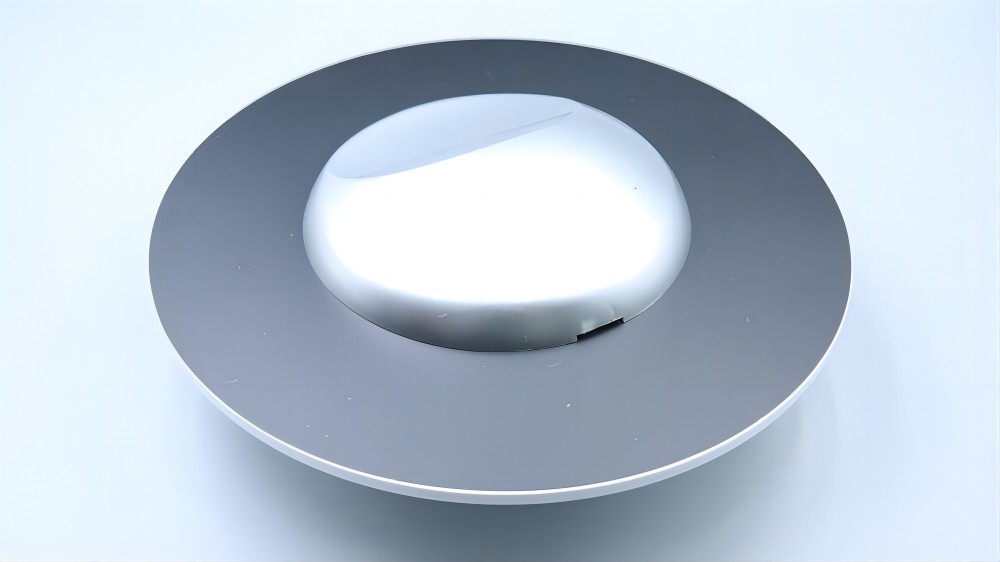

Leafing aluminium paste tends to rise to the surface of the paint film, creating a highly reflective, mirror-like finish. This type is ideal for applications where a strong metallic effect is desired. Non-leafing aluminium paste, on the other hand, is evenly distributed throughout the paint film, providing a uniform metallic sheen. This type is better suited for applications requiring consistent appearance and durability.

Properties of Aluminium Paste

Aluminium paste is known for its high reflectivity, which makes it an excellent choice for applications where a bright, metallic finish is required. Its compatibility with transparent colored pigments allows for the creation of vibrant, shimmering coatings. Additionally, aluminum paste offers good heat and corrosion resistance, enhancing the longevity of the products it is applied to.

Aluminium Paste Uses

- Automotive Industry: The automotive sector is a major consumer of aluminium paste. It is employed to create stunning interior and exterior finishes, lending vehicles a premium and luxurious look. Aluminium paste for paint is particularly sought after for wheel coatings, where it imparts a dazzling metallic shine that enhances the overall aesthetic appeal of the vehicle. Beyond aesthetics, aluminium paste can also be incorporated into performance coatings to provide heat resistance and corrosion protection.

- Building Materials: In the construction industry, aluminium paste is used in coatings for steel structures. Its ability to enhance the appearance and durability of buildings makes it a popular choice for architects and builders. Aluminium paste coatings can provide buildings with a modern, metallic look while also protecting them from corrosion and weathering. This dual function of aesthetics and protection is particularly valuable in urban environments where both visual appeal and longevity are important.

- 3C Consumer Products: Aluminium paste is also widely used in the manufacture of 3C (computer, communication, and consumer electronics) products. The metallic effect provided by aluminium paste makes electronic devices such as smartphones and tablets more attractive to consumers. Moreover, the aluminium paste is compatible with environmental standards, ensuring that it can be safely used in products that meet modern sustainability requirements.

- Paint Industry: The paint industry is one of the largest consumers of aluminium paste. It is used in a variety of coatings, including architectural, automotive, and furniture paints. Aluminium paste for paint is valued for its ability to provide unique metallic sheen and decorative effects. Architectural paints can be used to create eye-catching finishes for buildings, while furniture paints, add a luxurious touch to home decor. The versatility of aluminium paste pigment allows it to be used in both high-gloss and matte finishes, depending on the desired effect.

- Electronics Industry: In the electronics industry, aluminium paste is used for conductive coatings and electromagnetic shielding. The conductive properties of aluminium flakes make them suitable for applications where electrical conductivity is required. Aluminium paste can be applied to electronic components to protect them from electromagnetic interference, ensuring the reliable performance of electronic devices.

- Aerospace Sector: The aerospace industry utilizes aluminium paste for thermal protection coatings and conductive coatings on aircraft and rockets. The reflective properties of aluminium paste help protect these vehicles from extreme temperatures encountered during flight. Additionally, aluminium paste can be used to create conductive pathways on the surfaces of aerospace components, improving their overall performance and safety.

- Packaging Industry: In the packaging industry, aluminium paste is used to create metallic finishes on packaging materials. High-end packaging such as luxury boxes and labels benefit from the eye-catching appearance of aluminium paste. This not only enhances the visual appeal of the packaging but also adds a layer of protection against wear and tear.

- Plastics Industry: Aluminium paste is also employed as a filler and colourant in the plastics industry. It can be added to plastic products to provide them with a unique metallic sheen and texture. This is particularly useful in applications where aesthetic appeal is important, such as in consumer goods and automotive parts.

Role of Aluminium Paste in Paint

1. Functions in Paints

Aluminium paste plays a crucial role in paints, providing both functional and aesthetic benefits. One of its primary functions is to impart a metallic luster to the paint, giving surfaces a shiny, reflective finish. This metallic effect can vary from subtle to dramatic, depending on the concentration and type of aluminium paste used.

In addition to its decorative properties, aluminium paste enhances the durability and abrasion resistance of paints. This makes it particularly useful in applications where surfaces are subjected to heavy wear and tear, such as in automotive and industrial settings. Aluminum paste helps create a tough, resilient coating that can withstand scratches, impacts, and other forms of mechanical damage.

2. Types and Characteristics of Aluminium Paste Pigment

There are two main types of aluminum paste pigment used in paints: leafing and non-leafing.

- Leafing Aluminium Paste: This type of aluminium paste pigment tends to rise to the surface of the paint film, creating a highly reflective, mirror-like finish. The low surface tension of the aluminium flakes allows them to float to the top, forming a bright, metallic layer. Leafing aluminum paste pigment is often used in applications where a strong reflective effect is desired, such as in roof coatings and decorative finishes.

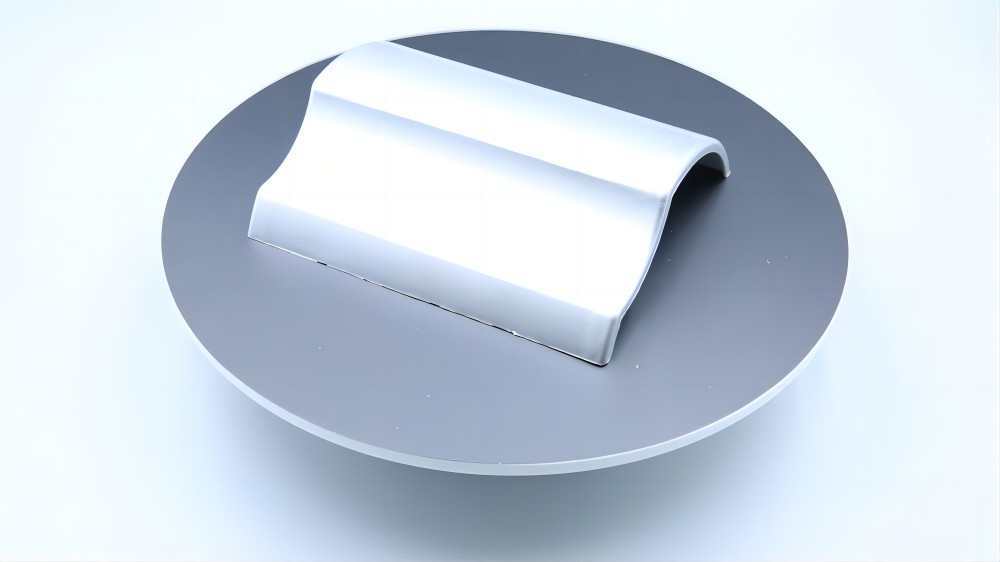

- Non-leafing Aluminium Paste: Non-leafing aluminium paste pigment is designed to remain evenly distributed throughout the paint film. The aluminum flakes are fully wetted by the paint medium, resulting in a uniform metallic sheen. This type of aluminum paste pigment is suitable for applications where a consistent appearance and durable coating are required, such as in automotive and furniture paints.

3. Benefits in Coatings

Aluminium paste for coatings due to its several benefits. Its high reflectivity enhances the visual appeal of painted surfaces, making them more attractive to consumers. The metallic sheen provided by aluminium paste can be customized to achieve various effects, from subtle highlights to bold, high-gloss finishes.

In addition to its aesthetic benefits, aluminium paste improves the performance of coatings. It enhances the durability and abrasion resistance of the paint, protecting surfaces from damage and extending the life of the coating. This makes aluminum paste an ideal choice for applications where long-lasting, high-performance coatings are required.

Differences Between Aluminum Paste and Ordinary Aluminum Powder

To better understand the key distinctions between aluminum paste and ordinary aluminum powder, consider the following table:

| Aspect | Aluminum Paste | Ordinary Aluminum Powder |

| Appearance and Form | Composed of flake-like aluminum particles suspended in a solvent medium. Flakes vary in size and thickness, generally have a bright, metallic sheen. Creates reflective, glossy finishes in paints and coatings. | Consists of fine, particulate aluminum particles. Typically dull and gray in color, lacking metallic luster. |

| Applications | Primarily used in paints, coatings, and inks to provide a metallic effect and enhance appearance. Widely used in automotive, construction, electronics, and packaging industries. | Used in industrial applications for high conductivity and reactivity. Common in metallurgy, chemical manufacturing, rocket fuel, and fireworks. |

| Performance Characteristics | Known for high reflectivity, heat resistance, and corrosion resistance. | Characterized by high reactivity and conductivity. |

Environmental Advantages of Aluminium Paste

The advantages of aluminium paste in environmental protection are mainly reflected in the following aspects:

- Low VOC Emissions: One of the key environmental advantages of aluminium paste is its low VOC (volatile organic compound) emissions. Traditional solvent-based paints can release significant amounts of VOCs into the atmosphere, contributing to air pollution and health problems. Aluminium paste, especially when used in water-based formulations, emits very low levels of VOCs, making it a more environmentally friendly choice.

- Non-Toxic and Safe: Aluminium paste is also non-toxic and safe to use. Water-based aluminium paste formulations do not contain harmful solvents, reducing the risk of health hazards for workers and end-users. This makes aluminium paste suitable for use in consumer products, where safety is a top priority.

- Non-Flammability: Water-based aluminium paste formulations are non-flammable, reducing the risk of fire during application and storage. This enhances the safety of using aluminium paste in various settings, from industrial facilities to home workshops.

- Compliance with Environmental Standards: Aluminium paste products can meet stringent environmental standards such as ROHS (Restriction of Hazardous Substances), PAHS (Polycyclic Aromatic Hydrocarbons), and EN71 (Safety of Toys). These standards limit the use of hazardous substances, ensuring that aluminium paste is safe for both the environment and human health.

- Reduced Environmental Impact: The use of aluminium paste helps reduce the environmental impact of coatings and paints. Its low VOC emissions and non-toxic properties contribute to cleaner air and safer workplaces. Additionally, the durability and performance of aluminium paste coatings can extend the life of products, reducing the need for frequent repainting and lowering overall material consumption.

- Economic and Environmental Benefits: Aluminium paste offers both economic and environmental benefits. Its high-quality coatings can improve the appearance and performance of products, adding value for manufacturers and consumers. At the same time, the environmental advantages of aluminium paste, such as reduced VOC emissions and compliance with environmental standards, support sustainable development and responsible manufacturing practices.

Conclusion

Aluminium paste stands as a testament to human ingenuity, transforming ordinary materials into extraordinary creations. Its ability to impart metallic brilliance, durability, and functionality has solidified its position as an indispensable ingredient in various industries. As technology continues to evolve, the potential applications of aluminium paste are boundless, promising to shape the future of design and innovation.

For high-quality aluminum paste that offers exceptional reflectivity, durability, and performance, consider CHAL aluminum paste. Its superior properties make it ideal for automotive, construction, electronics, and packaging applications. Choose CHAL for reliable, top-tier aluminum paste solutions.