Scaffolding has long been an essential component of construction, enabling workers to safely access elevated areas, transport materials, and carry out various tasks. Among the many types of scaffolding materials available today, aluminium scaffold tubes have emerged as a popular choice due to their unique combination of strength, lightweight properties, and durability. This article delves into the basic specifications of aluminium scaffold tubes and the key advantages they offer, making them a preferred choice in modern construction projects.

Basic Information About Aluminium Scaffold Tubes

Understanding the basic specifications of aluminium scaffold tubes is crucial to selecting the right materials for specific projects. This section discusses the tube diameter, wall thickness, and common materials used in their construction.

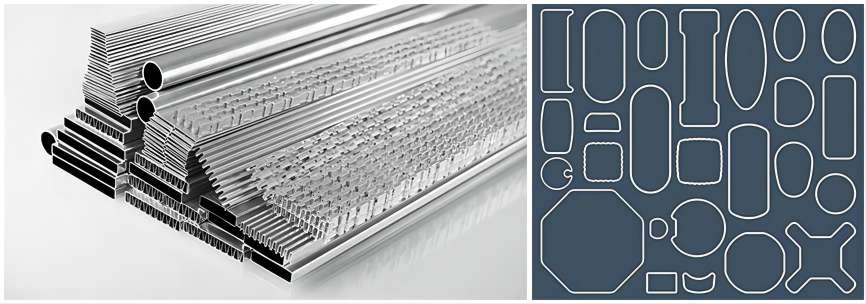

1. Tube Diameter

The diameter of aluminium scaffold tubes is a crucial factor that affects their functionality and suitability for different applications.

- Standard Diameter: Most aluminium scaffold tubes have a diameter of 48.3 mm, a widely accepted size in the construction industry.

- Load-Bearing Capacity: Larger diameters enhance strength and are suited for heavy-duty applications, while smaller diameters are used for lightweight or decorative structures.

- Compatibility: A 48.3 mm diameter ensures seamless integration with standard scaffolding components such as couplers, clamps, and fittings.

2. Wall Thickness

Wall thickness is another important specification that impacts the structural strength and usability of aluminium scaffold tubes.

- Typical Range: Common wall thicknesses range from 3.2 mm to 4.5 mm, depending on the project’s load and environmental conditions.

- Strength vs. Weight:

- Thicker Walls: Provide greater strength and durability, making them ideal for heavy-duty scaffolding systems.

- Thinner Walls: Reduce the overall weight of the scaffold, enhancing portability and ease of handling while maintaining adequate support for lighter tasks.

- Project Suitability: The selection of wall thickness should balance the need for durability and ease of use.

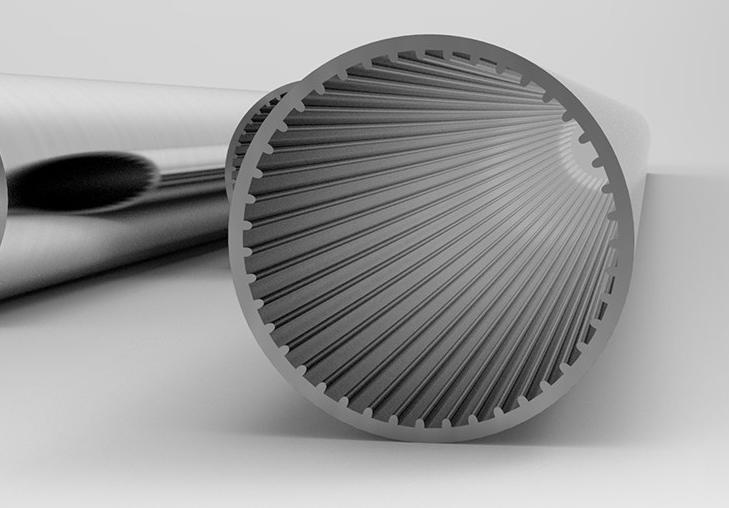

3. Common Materials

Aluminium scaffold tubes are typically made from high-grade aluminium alloys, such as 6061 and 6082, known for their excellent strength-to-weight ratios and corrosion resistance. These alloys combine aluminium with elements like magnesium and silicon to enhance their mechanical properties.

- 6061 Aluminium Alloy: Offers excellent corrosion resistance and medium-to-high strength, making it suitable for general scaffolding applications.

- 6082 Aluminium Alloy: Known for its high strength, this alloy is often used in load-bearing structures and high-stress environments.

The use of aluminium alloys ensures that scaffold tubes are lightweight yet strong enough to withstand the demands of construction work.

Advantages of Aluminium Scaffold Tubes

Aluminium scaffold tubes stand out for their numerous benefits, which make them a preferred material in various scaffolding applications. Below, we explore these advantages in detail.

1. Lightweight

One of the standout features of aluminium scaffold tubes is their lightweight nature. Aluminium is approximately two-thirds lighter than steel, which significantly reduces the physical effort required during transportation and assembly. This makes them ideal for large-scale projects where frequent relocation of scaffolding is necessary.

The reduced weight also lowers transportation costs, especially when scaffolding needs to be moved over long distances. Furthermore, workers can handle aluminium scaffold tubes with ease, leading to faster assembly and disassembly, which enhances overall project efficiency.

2. Corrosion Resistance

Aluminium is naturally resistant to rust and corrosion due to its ability to form a protective oxide layer when exposed to air. This property is especially beneficial for scaffolding used in outdoor environments, where exposure to rain, humidity, or even salty air (in coastal areas) can quickly degrade steel structures.

Unlike steel, which requires protective coatings or regular maintenance to prevent rust, aluminium scaffold tubes retain their integrity with minimal upkeep. This corrosion resistance translates to a longer lifespan and lower maintenance costs over time.

3. Durability

Despite being lightweight, aluminium scaffold tubes are incredibly strong and durable. They can withstand substantial loads without bending or breaking, making them suitable for a wide range of construction activities. The use of high-grade aluminium alloys ensures that these tubes maintain their strength even under extreme environmental conditions.

Whether it’s enduring the weight of heavy equipment or withstanding the pressures of high winds, aluminium scaffold tubes are built to perform reliably. Their durability makes them a long-term investment, as they are less likely to require replacement compared to other materials.

4. Cost-Effectiveness

While aluminium scaffold tubes may have a higher upfront cost than alternatives like steel, they offer excellent long-term value. Their low maintenance requirements, resistance to corrosion, and durability mean fewer replacements and repairs, which can result in significant cost savings over time.

Moreover, the lightweight nature of aluminium reduces labour costs during installation and dismantling. This cost-effectiveness is particularly evident in large-scale or repeated use projects, where the advantages of aluminium accumulate over time.

5. Environmental Friendliness

Aluminium is one of the most sustainable materials available, as it is 100% recyclable without losing its quality. Scrap aluminium can be melted down and repurposed into new products, significantly reducing waste and environmental impact.

In an era where sustainability is increasingly important, the use of aluminium scaffold tubes demonstrates a commitment to eco-friendly practices. Construction companies can benefit from this not only environmentally but also in terms of public perception and compliance with green building standards.

6. Ease of Assembly and Disassembly

The lightweight and modular design of aluminium scaffold tubes simplifies the assembly and disassembly process. Workers can quickly set up and dismantle scaffolding with minimal effort, which is particularly advantageous for projects with tight schedules.

This ease of handling also enhances workplace safety. Workers are less likely to suffer from fatigue or injuries caused by lifting heavy steel components, reducing the risk of accidents on-site.

7. Weather Resistance

Aluminium scaffold tubes perform exceptionally well in diverse weather conditions. Unlike steel, which can become brittle in freezing temperatures, aluminium maintains its strength and flexibility. Similarly, it does not expand or contract significantly in response to temperature changes, ensuring stability in both hot and cold climates.

This weather resistance makes aluminium scaffold tubes a reliable choice for construction projects in regions with extreme or fluctuating weather conditions.

Comparison with Traditional Steel Scaffolding

| Feature | Aluminium Scaffolding | Steel Scaffolding |

| Weight | Significantly lighter, reducing labor costs and improving efficiency during transportation, assembly, and dismantling. | Heavier, requiring more labor and equipment for handling and installation. |

| Corrosion Resistance | Highly resistant to corrosion, especially in harsh environments, extending the lifespan of the scaffolding. | Prone to rust and corrosion, especially in humid or coastal areas, requiring frequent maintenance and replacement. |

| Strength-to-Weight Ratio | Excellent strength-to-weight ratio, ensuring structural integrity and safety, even under heavy loads. | High strength-to-weight ratio, but heavier than aluminium, leading to increased transportation and installation costs. |

| Versatility | Highly versatile, adaptable to various shapes and configurations, making it suitable for a wide range of construction projects. | Less versatile, often requiring more complex assembly and dismantling procedures. |

| Cost | Higher initial cost due to the premium material, but lower long-term costs due to reduced maintenance, longer lifespan, and improved efficiency. | Lower initial cost, but higher long-term costs due to frequent maintenance, shorter lifespan, and potential for premature failure. |

| Maintenance | Low maintenance requirements, primarily involving cleaning and inspection. | High maintenance requirements, including regular painting, rust removal, and structural inspections. |

| Environmental Impact | Environmentally friendly, being highly recyclable and reducing the carbon footprint of construction projects. | Less environmentally friendly, contributing to waste and pollution due to its limited recyclability and maintenance requirements. |

By considering these factors, it is evident that aluminium scaffolding offers significant advantages over traditional steel scaffolding, making it a more cost-effective and sustainable solution for modern construction projects.

Applications of Aluminium Scaffold Tubes

Aluminium scaffold tubes find applications in a wide range of construction and maintenance projects:

- High-Rise Buildings: Aluminium scaffolding is ideal for constructing tall buildings, providing safe access for workers at elevated heights.

- Bridges: During bridge construction and maintenance, aluminium scaffolding offers stability and safety, even in challenging environments.

- Industrial Facilities: In industrial settings, aluminium scaffolding is used for maintenance, repair, and installation work.

- Painting and Decorating: Aluminium scaffolding provides a stable platform for painters and decorators to work efficiently and safely.

- Roofing: For roofing projects, aluminium scaffolding offers a secure and sturdy working surface.

- Electrical Work: Electricians often use aluminium scaffolding to access power lines and electrical equipment safely.

Overall, aluminium scaffold tubes have revolutionized the construction industry by offering a superior alternative to traditional steel scaffolding. Their lightweight, durable, and versatile nature makes them a preferred choice for modern construction projects. By embracing aluminium scaffolding, construction companies can improve efficiency, enhance safety, and reduce their environmental impact. As technology continues to advance, we can expect to see even more innovative applications of aluminium scaffold tubes in the future.