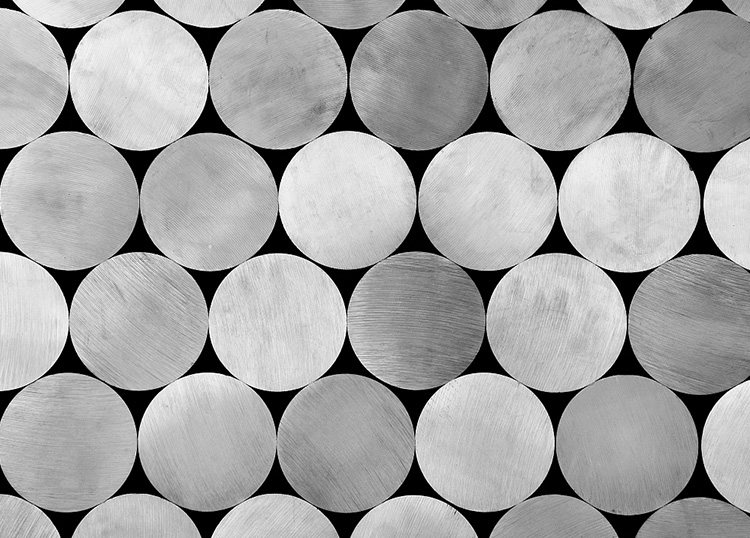

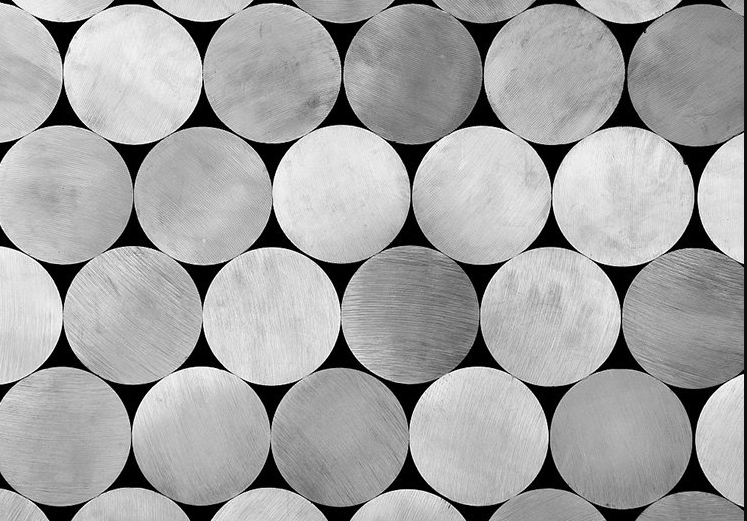

Aluminum billet refers to a semi-finished product made of aluminum that is typically in a cylindrical or rectangular shape. It is produced through a process called casting or extrusion, where molten aluminum is poured into a mold or forced through a die to obtain the desired shape.

Manufacturing Process of Aluminum Billet

The manufacturing process of aluminum billet typically involves several steps to transform raw aluminum material into a semi-finished form suitable for further processing. Here are the 4 main steps including the selection of raw materials, melting and alloying, billet casting or extrusion, and cooling.

1 Selection of Raw Materials

The process begins with the selection of raw materials. Aluminum billets are typically made from aluminum scraps or primary aluminum. The choice of raw materials depends on factors such as cost, desired alloy composition, and availability.

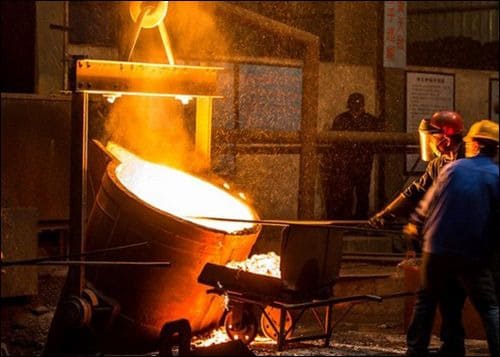

2 Melting and Alloying

The selected aluminum raw materials are melted in a furnace. The furnace is typically a large, high-temperature vessel capable of reaching temperatures above the melting point of aluminum, which is around 660 degrees Celsius (1220 degrees Fahrenheit).

In the melting process, aluminum scraps or primary aluminum are heated until they reach a liquid state. If the desired alloy composition requires additional elements, alloying elements like copper, magnesium, silicon, or zinc may be added to the molten aluminum.

The alloying elements are carefully measured and added to achieve the desired alloy composition and specific properties.

3 Billet Casting or Extrusion

There are two primary methods for forming aluminum billets: casting and extrusion.

- Casting

In the casting process, the molten aluminum is poured into a mold. The mold is typically made of steel and is pre-designed to the desired shape and dimensions of the billet. The mold can be cylindrical or rectangular, depending on the intended application.

The molten aluminum fills the mold, taking the shape of the mold cavity. The mold is designed to allow for the proper solidification of the aluminum.

Cooling channels or water jackets may be used to control the cooling rate of the aluminum and ensure uniform solidification throughout the billet.

- Extrusion

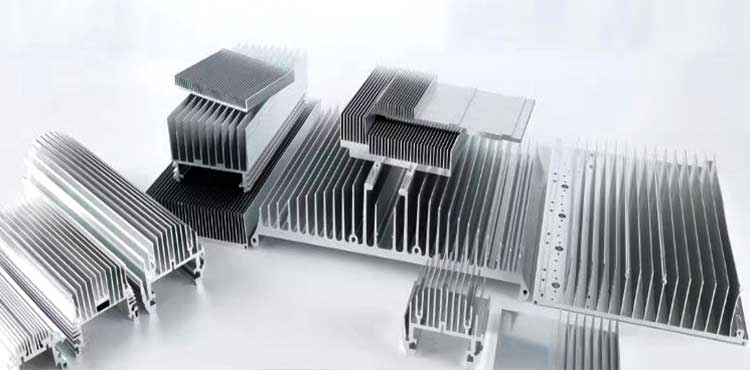

In the extrusion process, the aluminum billet is formed by forcing the heated aluminum through a specially designed die. The die determines the shape and dimensions of the billet.

The heated billet is placed into an extrusion press, which consists of a ram or piston that applies high pressure to the billet, forcing it through the die opening.

As the billet is pushed through the die, it takes on the shape of the die opening, resulting in a solidified aluminum billet with the desired cross-sectional shape.

4 Cooling

After the billet is formed through casting or extrusion, it is allowed to cool and solidify. The cooling process is crucial to achieve the desired metallurgical properties and structural integrity.

The cooling rate is carefully controlled to ensure uniform solidification and prevent internal defects in the billet. Cooling can be facilitated through various means, such as natural air cooling or water quenching, depending on the specific requirements of the aluminum alloy being used.

Types and Grades of Aluminum Billet

There are various types and grades of aluminum billet available, each with its own specific properties and applications. Here are some common types and their associated applications:

Pure Aluminum Billet

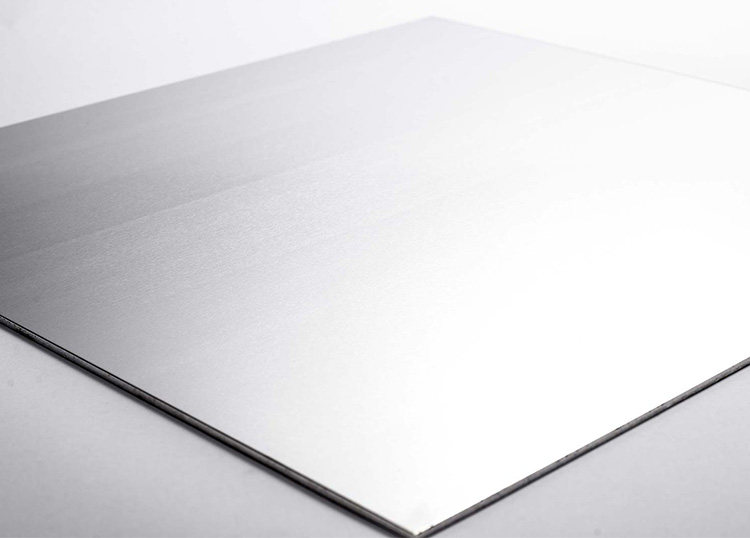

Pure aluminum billet, often referred to as 1000 series aluminum, consists of aluminum with a purity of 99% or higher.

It is commonly used in applications where corrosion resistance and electrical conductivity are essential, such as electrical wiring, conductors, and architectural components.

Aluminum Alloy Billet

Aluminum alloy billets are made by adding alloying elements to aluminum, resulting in enhanced mechanical properties and specific characteristics.

- 6000 Series: This series, including alloys like 6061 and 6063, is known for its excellent strength-to-weight ratio, weldability, and corrosion resistance. It is widely used in applications such as structural components, frames, extrusions, and automotive parts.

- 7000 Series: Alloys within this series, such as 7075, exhibit high strength, good fatigue resistance, and excellent machinability. They find applications in aerospace, automotive, and sporting goods industries, where strength and toughness are critical.

- 5000 Series: Alloys like 5052 and 5083 in this series offer good corrosion resistance, moderate strength, and excellent formability. They are commonly used in marine applications, transportation, and architectural components.

- 3000 Series: Alloys within this series, such as 3003 and 3105, have good formability, moderate strength, and excellent corrosion resistance. They are used in applications like roofing, siding, heat exchangers, and general sheet metal work.

Specialized Aluminum Billet:

Some specialized aluminum billets are designed for specific applications, often requiring unique properties or alloy compositions.

- High-Strength Aluminum Billet: These billets are engineered to provide exceptional strength and lightweight properties. They find applications in aerospace, military, and high-performance automotive industries.

- Heat-Treatable Aluminum Billet: These billets are designed to be heat-treated to achieve specific mechanical properties. They are used in applications where high strength and durability are required, such as in structural components and transportation industries.

It’s important to note that the specific applications of different grades of aluminum billet can vary depending on the industry, regulatory requirements, and engineering considerations. Our customers often select the appropriate grade based on factors such as mechanical properties, corrosion resistance, formability, and cost-effectiveness to meet the specific needs of their application. If you are looking for a manufacturer specialized in aluminum billet and other aluminum products, please feel free to contact us.

Related Products

Related Articles