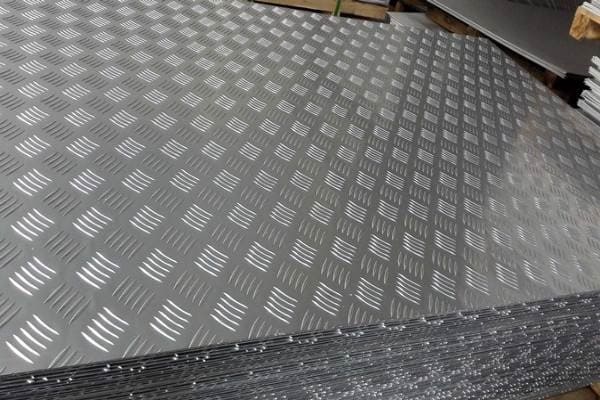

Aluminum checker plate, also known as aluminum tread plate, is a versatile material widely used in construction, transportation, and industrial applications. Its defining characteristic is the raised diamond or linear pattern on its surface, which provides exceptional slip resistance. Understanding the different material classifications and their properties is vital for selecting the most suitable aluminum checker plate for a specific project. Additionally, surface treatments significantly influence the performance and aesthetics of the plate.

Material Classification of Aluminum Checker Plate

The categorization of aluminum checker plate is primarily based on the type of aluminum alloy used in its manufacturing process. Each alloy has a unique chemical composition that dictates its properties, making it suitable for various applications. Here’s a breakdown of some common aluminum checker plate materials:

- 1060 Aluminum Alloy: This grade offers the highest level of purity, containing over 99.6% aluminum. This translates to excellent electrical and thermal conductivity. Due to its soft nature, 1060 aluminum checker plate boasts superior workability, making it ideal for applications where bending or forming is required. However, its low strength makes it unsuitable for high-stress environments. The affordability of 1060 aluminum checker plate makes it a popular choice for applications such as cold storage walls, decorative interior panels, and lightweight packaging materials.

- 3003 Aluminum Alloy: Often referred to as commercially pure aluminum, 3003 offers a good balance between workability and strength compared to 1060. It contains a small amount of manganese, enhancing its strength and offering moderate rust resistance. This makes 3003 aluminum checker plate a suitable choice for applications that require some level of corrosion protection, such as truck bed liners, non-critical building exterior panels, and moderately humid environments.

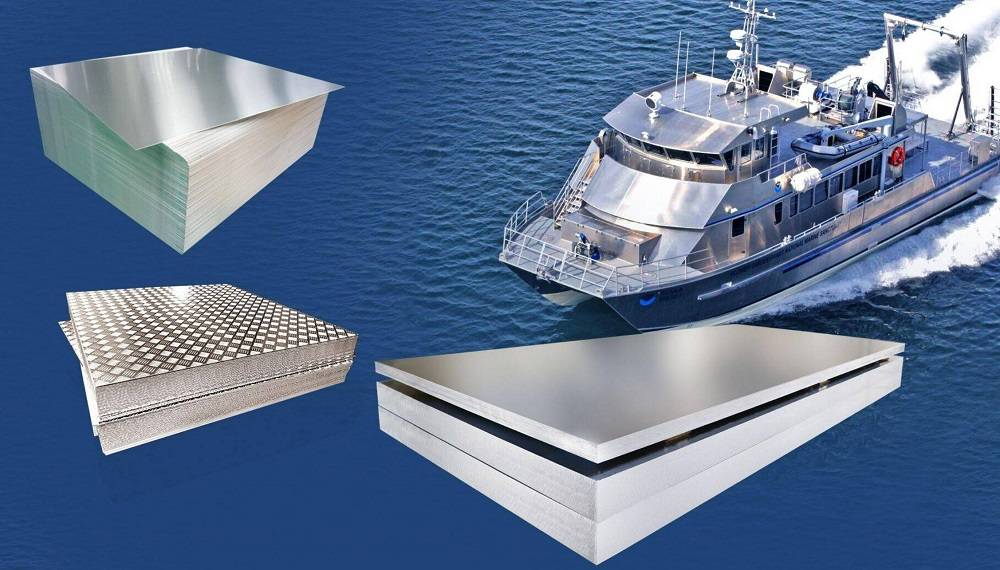

- 5052/5083 Aluminum Alloy: Belonging to the 5000 series, these alloys are known for their exceptional corrosion resistance. The presence of magnesium in their composition significantly enhances their ability to withstand harsh environments, including saltwater exposure. 5052/5083 aluminum checker plate demonstrates superior strength compared to the previously mentioned options. This combination of strength and corrosion resistance makes it ideal for applications like boat decks, car washes, chemical processing plants, and offshore structures.

- 6061/6063 Aluminum Alloy: These alloys are part of the 6000 series, known for their high strength-to-weight ratio. They achieve this through the addition of magnesium and silicon to their composition. 6061/6063 aluminum checker plate offers excellent strength, good corrosion resistance, and superior weldability. These properties make it a popular choice for demanding applications in construction, such as walkways, mezzanines, and machine platforms. It’s also commonly used in the transportation industry for truck beds and trailers.

Properties Analysis of Aluminum Checker Plate

When selecting an aluminum checker plate, it’s crucial to consider several key properties beyond its material classification. These properties influence the suitability of the plate for a specific application.

- Mechanical Properties: These properties define the physical strength and behavior of the aluminum checker plate under stress. They include:

- Tensile Strength: This measures the maximum stress a material can withstand before pulling apart.

- Yield Strength: This indicates the stress level at which the material begins to deform plastically.

- Elongation: This represents the percentage a material can stretch before breaking.

For instance, a properly heat-treated 6061 aluminum checker plate can achieve a tensile strength of 470MPa, a yield strength of 325MPa, and an elongation of 10%.

- Corrosion Resistance: This property determines the material’s ability to resist rust and degradation caused by environmental factors. The level of corrosion resistance varies depending on the alloy composition. 3003 aluminum checker plate offers moderate rust resistance, while 5052/5083 demonstrates superior resistance to saltwater corrosion.

- Workability: This refers to the ease with which the aluminum checker plate can be formed or shaped. 6000 series alloys, like 6061/6063, possess good workability due to the presence of magnesium and silicon, making them suitable for applications requiring bending or fabrication.

- Surface Treatment: This process significantly impacts the final performance and appearance of the aluminum checker plate. We’ll explore various surface treatments in detail in a later section.

Surface Treatment of Aluminum Checker Plate

Aluminum checker plates can undergo various surface treatments to enhance their functionality and aesthetics. These treatments create a protective layer that improves properties like wear resistance, corrosion protection, and visual appeal. Here’s an overview of common surface treatments:

- Anodizing: This electrochemical process creates a hard, microscopic oxide layer on the aluminum surface. This oxide layer offers excellent wear resistance, making an anodized aluminum checker plate ideal for high-traffic areas. Additionally, the layer can be dyed in a variety of colors, providing an aesthetically pleasing finish. A key advantage of anodizing is the strong bond between the oxide layer and the aluminum, ensuring a durable and long-lasting finish.

- Painting: This method involves applying a liquid paint coating to the aluminum checker plate. Paint offers a wide range of color options and can be formulated to provide additional properties like UV protection or chemical resistance. However, painted surfaces may be susceptible to scratches and chipping compared to anodizing. Single or multi-color finishes are achievable, and some techniques even allow for creating gradient effects.

- Laminating: This process involves applying a thin film to the aluminum checker plate surface. The film can be made from various materials, including plastic, wood grain simulations, or even other metals. Lamination offers a cost-effective way to achieve a decorative finish that mimics natural textures like wood or stone. However, the longevity of the laminated surface depends on the quality of the film and its adhesion to the aluminum. Exposure to harsh weather conditions or strong solvents might cause the film to peel or discolor over time.

- Electrophoretic Painting (E-coating): This method utilizes an electric current to deposit a uniform layer of paint onto the aluminum checker plate. E-coating offers exceptional adhesion and a smooth, consistent finish. It’s particularly well-suited for complex shapes as the electrical current ensures even paint distribution in all areas. While E-coating provides excellent corrosion resistance and durability, the process can be more complex and expensive compared to traditional painting methods.

- Chemical Oxidation: This process involves treating the aluminum checker plate with a chemical solution that creates a thin oxide layer on the surface. This layer offers some level of corrosion protection, but it typically has a limited color range, often appearing light brown or grayish. Chemical oxidation is a cost-effective option for applications where basic corrosion resistance is needed, but aesthetics are not a primary concern.

- Plating: This method involves depositing a thin layer of another metal or material onto the aluminum checker plate surface. Common plating materials include chromium, nickel, or even precious metals like gold. Plating can enhance corrosion resistance, improve wear properties, or provide a decorative finish. However, the cost and complexity of the plating process increase with the chosen material.

Influence of Surface Treatment on Mechanical Properties

The selection of a surface treatment for aluminum checker plate can influence its mechanical properties. Here’s how some treatments can impact performance:

- Fatigue Performance: Fatigue refers to the weakening of a material over time when subjected to repeated stress. Surface treatments like anodizing can improve fatigue performance by creating a harder and more wear-resistant surface. This reduces the formation and propagation of cracks, leading to a longer lifespan for the aluminum checker plate.

- Corrosion Resistance: As mentioned earlier, some surface treatments, like anodizing and certain types of painting, create a barrier that protects the underlying aluminum from corrosion. This extends the service life of the plate, particularly in harsh environments.

- Surface Roughness: The texture of the aluminum checker plate surface, also known as its roughness, can affect its performance. Some surface treatments, like sandblasting, can increase surface roughness. While this enhances slip resistance, it can also concentrate stress at specific points, potentially reducing fatigue strength. Conversely, polishing can create a smoother surface, improving fatigue resistance but compromising slip resistance.

- Residual Stress: Certain surface treatments, particularly those involving high temperatures like anodizing or welding, can introduce residual stress into the aluminum checker plate. Residual stress can negatively impact the mechanical properties of the plate. However, techniques like controlled cooling during heat treatment can help mitigate residual stress and optimize the overall performance of the aluminum checker plate.

Conclusion

Selecting the right aluminum checker plate for your project requires careful consideration of both the material classification and the surface treatment. Understanding the properties of different alloys and how surface treatments affect them is crucial for ensuring optimal performance and longevity. By choosing the right combination of material and treatment, you can leverage the exceptional strength, corrosion resistance, and slip resistance of aluminum checker plate in a wide variety of applications.