Aluminum checker plate and aluminum diamond plate are both types of metal sheets with a raised, textured surface. The two materials are often used interchangeably, but there are some key differences between them. This article delves into the variations in surface treatments between aluminum checker plates and aluminum diamond plate, and how to choose the right aluminum plates.

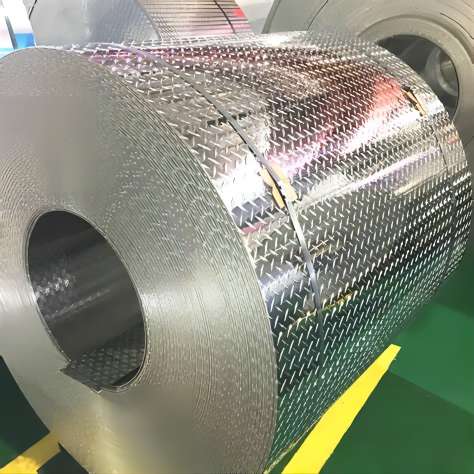

What Is Aluminum Checker Plate?

Aluminum checker plate is made by passing a sheet of aluminum through a series of rollers that deform it into a checkerboard pattern. The checkerboard pattern can be created with different-sized squares, and the depth of the raised pattern can also vary. Aluminum checker plate is typically used in applications where a slip-resistant surface is required, such as on stairs, ramps, and walkways. It is also used in industrial settings where there is a risk of employees slipping and falling.

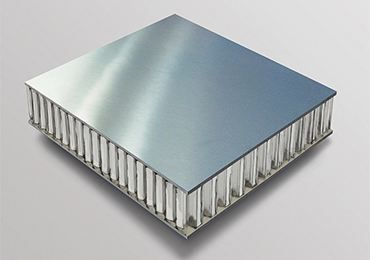

What Is Aluminum Diamond Plate?

Aluminum diamond plate is made by passing a sheet of aluminum through a series of rollers that create a diamond-shaped pattern. The diamond-shaped pattern can be created with different-sized diamonds, and the depth of the raised pattern can also vary. Aluminum diamond plate is typically used in applications where a slip-resistant surface is required and where a high degree of durability is also needed. For example, it is often used on the floors of loading docks, warehouses, and other areas where there is a lot of foot traffic. It is also used on the exterior of vehicles, such as trucks and boats, where it can help to protect the vehicle from scratches and dents.

How Is Aluminum Checker Plate and Diamond Plate Surface Treated?

The surface treatment of aluminum checker plate and diamond plate can affect the appearance, slip resistance, and durability of the material. The most common methods of surface treatment for aluminum checker plate and diamond plate are:

- Hot rolling: This is the most common method of producing aluminum checker plate and diamond plate. In this process, the aluminum sheet is passed through a series of rollers that deform it into the desired shape. Hot rolling produces a smooth surface with a uniform texture.

- Chemical etching: This process can be used to create a more textured surface on aluminum checker plate or diamond plate. In chemical etching, the aluminum sheet is submerged in a chemical bath that etches away the surface, leaving a raised pattern. Chemical etching can produce a variety of patterns, including checkerboard, diamond, and waffle patterns.

- Sandblasting: This process can also be used to create a textured surface on aluminum checker plate or diamond plate. In sandblasting, the aluminum sheet is blasted with sand or another abrasive material, which removes the surface and leaves a raised pattern. Sandblasting can produce a variety of patterns, including checkerboard, diamond, and waffle patterns.

- Mechanical pressing: This process can be used to create a diamond plate pattern on aluminum sheet. In mechanical pressing, a mold with the desired pattern is used to press the aluminum sheet into shape. Mechanical pressing produces a diamond plate pattern with a very smooth surface.

Which Is Better: Aluminum Checker Plate or Aluminum Diamond Plate?

The best surface treatment for aluminum checker plate or diamond plate depends on the specific application. For applications where slip resistance is critical, aluminum diamond plate is the better choice. The raised diamond pattern provides excellent traction and helps to prevent slips and falls. For applications where cost and ease of fabrication are more important, aluminum checker plate is a good option. The checkerboard pattern is still slip-resistant, but it is not as durable as the diamond pattern.

Conclusion

Aluminum checker plate and aluminum diamond plate are both versatile materials that can be used in a variety of applications. The best surface treatment for a particular application will depend on the specific requirements. If you are looking for a slip-resistant surface with high durability, then aluminum diamond plate is the better choice. If you are looking for a more affordable option with good slip resistance, then aluminum checker plate is a good option.

Additional considerations

In addition to surface treatment, there are a few other factors to consider when choosing between aluminum checker plate and aluminum diamond plate. These factors include:

- Thickness: Aluminum checker plate and diamond plate are available in a variety of thicknesses. The thickness of the material will affect the weight and strength of the sheet. For applications where strength is important, a thicker sheet may be required.

- Finish: Aluminum checker plate and diamond plate can be finished in a variety of ways. The finish can affect the appearance and corrosion resistance of the material. For applications where corrosion resistance is important, an anodized or powder coated finish may be required.

- Cost: Aluminum checker plate and diamond plate are both relatively affordable materials. However, aluminum diamond plate may be slightly more expensive due to the more complex manufacturing process.

Ultimately, the best way to choose between different finishes of aluminum checker plate and diamond plate is to consider the specific requirements of the application.