Whether in construction, architecture, or manufacturing, achieving perfect angles and edges is a critical goal. Aluminum corner extrusions offer an effective solution for these requirements, providing clean, seamless connections and enhancing the overall strength and design of projects. These extruded aluminum shapes, typically L-shaped, T-shaped, or angle-shaped, offer precise angles and edges, playing an important role in structural support, framing, and decorative elements. Here we will explore their types, applications, and advantages, and discuss how to select the right extrusion for your specific project.

What Are Aluminum Corner Extrusions?

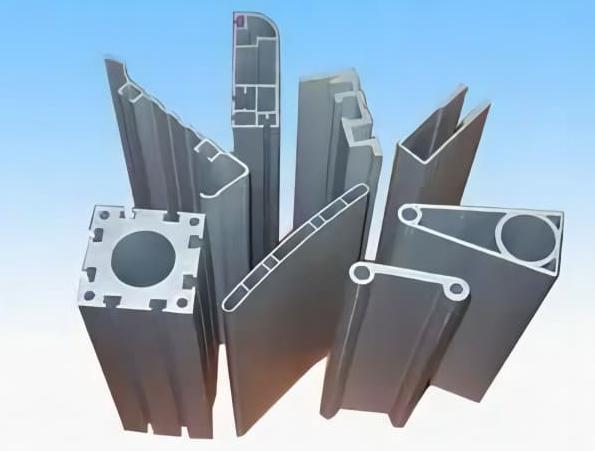

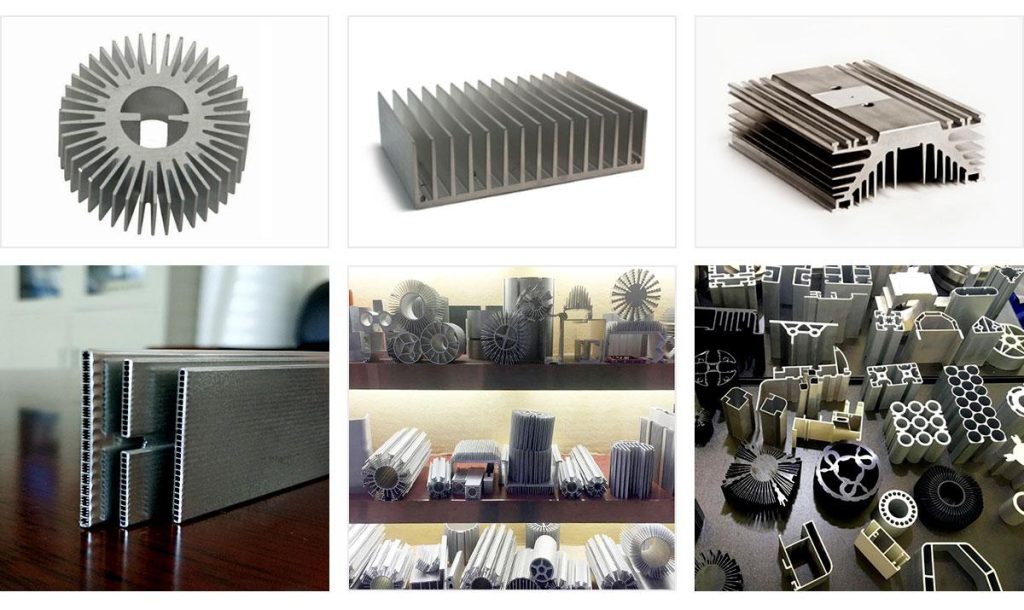

Aluminum corner extrusions are manufactured through a process called aluminum extrusion, which involves shaping aluminum by forcing it through a die with the desired profile. This process results in components with consistent dimensions, sharp corners, and smooth edges. Aluminum corner extrusions come in various shapes and designs, each tailored for specific applications. The most common shapes include:

| Type of Aluminum Corner Extrusion | Description | Common Applications |

| Equal Angle Extrusions | Two sides of different lengths, meet at a 90-degree angle. | Structural frameworks |

| Window/door frames | ||

| Shelving units | ||

| Unequal Angle Extrusions | Two sides of different lengths, meeting at a 90-degree angle. | Furniture construction |

| Shelving and framing | ||

| Edging and corner protection | ||

| L-Shaped (Right-Angle) Extrusions | Basic 90-degree angle extrusion for corner reinforcement. | Door/window frames |

| Furniture/cabinetry construction | ||

| Decorative trim | ||

| Corner Guard Extrusions | Designed to protect corners from impact and wear. | Wall corner protection |

| High-traffic areas | ||

| Industrial/commercial buildings | ||

| T-Slot Extrusions | T-shaped groove allowing attachment of panels and accessories. | Industrial frameworks |

| Modular systems | ||

| Machine guards/enclosures | ||

| Bullnose Extrusions | Rounded outer corner for smooth, decorative edges. | Architectural trim |

| Furniture design | ||

| Decorative edges (e.g., countertops) | ||

| Radius Corner Extrusions | Soft, curved corners for aesthetics and reduced stress. | Architectural framing |

| Furniture/cabinetry | ||

| Decorative elements | ||

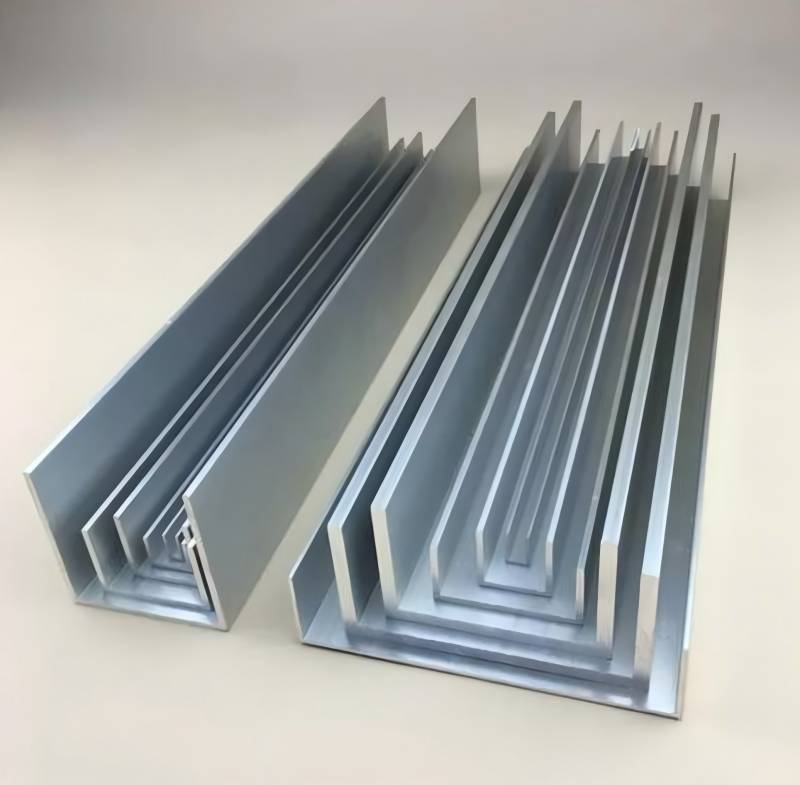

| Channel Extrusions | Uor C-shaped profile that fits around edges of panels. | Securing panels in construction |

| Furniture assembly | ||

| Edge trim |

Aluminum corner extrusions play a crucial role in various industries due to their versatility, durability, and cost-effectiveness. The different types of extrusions allow for precise applications across construction, industrial, and decorative fields, making them an indispensable part of modern building and manufacturing projects.

How Aluminum Corner Extrusions Achieve Perfect Angles and Edges

Achieving perfect angles and edges is critical in construction and manufacturing. Aluminum corner extrusions are designed to create sharp, clean corners while maintaining structural integrity. These extrusions ensure that corners fit perfectly, without gaps, misalignments, or weak points. The key to this precision lies in the flexibility of the extrusion process and the malleability of aluminum.

Precision in Design and Installation

Aluminum corner extrusions are produced with high precision, which allows for seamless fitting in various projects. Their precise angles and uniform profiles enable them to slot perfectly into place, ensuring that corners and edges align accurately. Moreover, custom extrusions can be designed to meet specific angle requirements, such as those used in architectural designs or specialized equipment.

Durability and Structural Integrity

In addition to providing clean corners, aluminum corner extrusions also enhance the strength of the overall structure. The aluminum alloy’s inherent strength, combined with the extrusion’s design, ensures that the edges remain stable and resist deformation, even under pressure. This makes them ideal for load-bearing applications, such as structural framing or protective edge guards.

So aluminum corner extrusions can create flawless, aesthetically pleasing corners while contributing to the structural soundness of the project. By using precision-engineered aluminum extrusions, builders and manufacturers can ensure that their corners and edges are both visually and functionally perfect.

How to Choose the Right Aluminum Corner Extrusion

Choosing the right aluminum corner extrusion depends on several factors, including the project’s specific needs, environmental conditions, and aesthetic goals. Here are key considerations to keep in mind when selecting the ideal extrusion for your project:

1. Project Requirements

First, identify the project’s specific requirements. Are you looking for structural reinforcement, aesthetic enhancement, or protective elements? Different types of extrusions are suited for different purposes. For instance, equal angle extrusions may be better for load-bearing applications, while bullnose extrusions are ideal for decorative corners.

2. Material Thickness and Load Capacity

Consider the load the extrusion will bear. Thicker aluminum extrusions are generally stronger and more suitable for structural applications, whereas thinner extrusions are better for decorative and lightweight needs. Be sure to choose an extrusion that can handle the stress it will be subjected to.

3. Surface Finish

Aluminum extrusions can be finished in various ways, including anodizing, powder coating, and painting. The right finish can improve corrosion resistance, add aesthetic appeal, or provide added durability. If the project is outdoors or exposed to harsh environments, a protective finish is essential.

4. Customization Options

In some cases, a standard extrusion may not meet your needs, and a custom profile is required. Consider whether you need a custom shape or size to fit your design specifications. Many manufacturers offer custom extrusion services that allow for unique angles, lengths, and finishes.

5. Environmental Considerations

If the extrusion will be used in environments prone to moisture, corrosion, or extreme temperatures, select an aluminum alloy and surface treatment that offers the required level of protection. Marine-grade aluminum, for example, offers superior resistance to corrosion in wet environments.

Aluminum corner extrusions provide a versatile, durable, and aesthetically pleasing solution for projects that require perfect angles and edges. Whether used for structural reinforcement, edge protection, or decorative purposes, these extrusions offer multiple benefits, including lightweight strength, corrosion resistance, and customizability. With the right aluminum corner extrusion, builders and manufacturers can achieve precise, flawless corners that enhance both the form and function of their designs.