Cosmetic tubes have become an indispensable part of the beauty industry, offering convenient and hygienic packaging for a wide range of products. Among the various materials used for tube manufacturing, aluminum stands out as a preferred choice due to its exceptional properties and environmental sustainability. This article provides a comprehensive overview of aluminum cosmetic tubes, exploring their manufacturing process, common applications, and the importance of proper recycling.

What are Aluminum Cosmetic Tubes?

Aluminum cosmetic tubes are cylindrical or oval containers primarily made from aluminum metal. They are characterized by their lightweight, collapsible nature, and high durability. Unlike plastic tubes, aluminum offers excellent barrier properties, effectively shielding the enclosed product from light, air, and moisture. This ensures product stability, maintaining its quality and efficacy throughout its shelf life.

How are Aluminum Cosmetic Tubes Made?

The manufacturing process of aluminum cosmetic tubes involves several key steps:

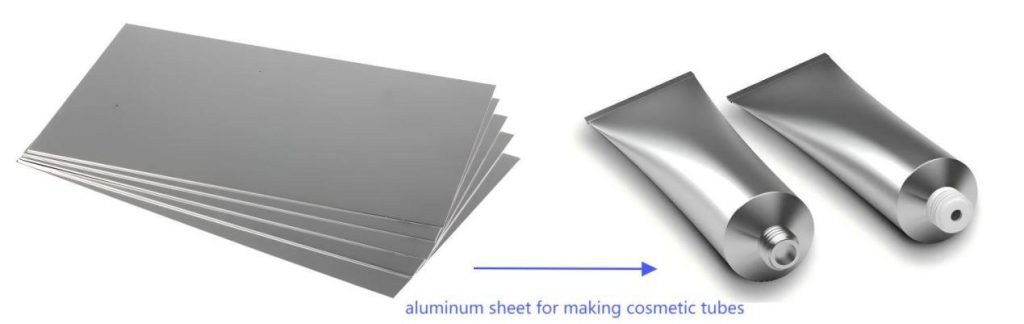

- Raw Material Preparation: The process begins with the preparation of the raw material – aluminum sheet or coil. This material undergoes rigorous quality checks to ensure it meets specific standards for strength, thickness, and purity.

- Tube Forming: The aluminum sheet or coil is then fed into specialized machinery where it is shaped and sized into tubes. This process involves precise cutting, forming, and joining techniques to create the desired tube dimensions.

- Printing and Decoration: Once the tubes are formed, they undergo printing and decoration processes. This can involve various techniques such as offset printing, gravure printing, silk-screen printing, and hot stamping to apply brand logos, product information, and attractive designs.

- Nozzle and Closure Attachment: After decoration, the tubes are fitted with appropriate nozzles and closures. Nozzles can vary in design depending on the product consistency and application method (e.g., cream, gel, liquid). Closures can range from simple screw-on caps to more sophisticated mechanisms like flip-top caps or pump dispensers.

- Quality Control Checks: Throughout the manufacturing process, rigorous quality control checks are conducted at each stage to ensure that the tubes meet strict standards for dimensions, weight, appearance, and functionality.

- Filling and Sealing: Finally, the tubes are filled with the cosmetic product and sealed to prevent leakage and contamination. This process is typically automated to ensure consistent filling and efficient production.

What are the Common Uses for Aluminum Cosmetic Tubes?

The versatility of aluminum cosmetic tubes makes them suitable for a wide range of products across the beauty and personal care industry:

| Applications | Description |

| Toothpaste | A classic application, aluminum tubes provide excellent protection, preventing moisture absorption and maintaining freshness. |

| Creams | Ideal for facial moisturizers, hand creams, and body lotions, offering a convenient and hygienic dispensing method. |

| Lotions | The collapsible nature ensures smooth and efficient dispensing of liquid lotions. |

| Gels | Suitable for hair gels, styling gels, and other gel-based products, ensuring effective packaging. |

| Shampoos | Commonly used for travel-sized shampoos, providing portability and convenience. |

| Deodorants | Maintains deodorant efficacy by preventing drying out and preserving fragrance. |

| Sunscreens | Shields sunscreens from UV rays, maintaining their stability and effectiveness. |

| Paints | Frequently used for artist paints, offering a durable and convenient container. |

Are Aluminum Cosmetic Tubes Recyclable?

One of the most significant advantages of aluminum cosmetic tubes is their high recyclability. Aluminum is an infinitely recyclable material, meaning it can be melted down and reformed into new products indefinitely without any loss of its original properties. This makes aluminum a highly sustainable packaging choice, minimizing its environmental impact.

The Recycling Process:

Collection and Sorting: Empty aluminum tubes are collected through curbside recycling programs, recycling centers, and other collection initiatives. They are then sorted to separate them from other types of waste.

Melting and Reprocessing: The collected aluminum tubes are transported to recycling facilities where they are melted down at high temperatures. This process transforms the used tubes back into molten aluminum.

Creation of New Products: The molten aluminum is then used to create a wide range of new products, including:

- New aluminum cans and packaging.

- Building materials.

- Transportation components.

- Consumer electronics.

Environmental Benefits of Recycling Aluminum:

- Reduced Energy Consumption: Recycling aluminum requires significantly less energy compared to producing aluminum from raw materials (bauxite ore). This translates to lower greenhouse gas emissions and a reduced carbon footprint.

- Conservation of Natural Resources: Recycling aluminum conserves valuable natural resources, such as bauxite ore, which is mined from the earth.

- Reduced Landfill Waste: By recycling aluminum tubes, we can divert them from landfills, reducing the amount of waste that ends up in our environment.

- Preservation of Natural Habitats: Minimizing the need for bauxite mining helps to protect natural habitats and biodiversity.

How to Dispose of Aluminum Cosmetic Tubes?

To ensure that your aluminum cosmetic tubes are properly recycled, follow these simple steps:

- Empty the Tube: Empty the tube completely of the cosmetic product.

- Rinse the Tube: Rinse the tube thoroughly with water to remove any remaining product residue.

- Check Local Recycling Guidelines: Familiarize yourself with your local recycling guidelines. Some communities may have specific instructions for disposing of aluminum tubes, such as placing them in designated recycling bins or dropping them off at recycling centers.

- Participate in Recycling Programs: Actively participate in local recycling programs to ensure that your aluminum tubes are properly collected and recycled.

Aluminum cosmetic tubes represent a sustainable and effective packaging solution for the beauty industry. Their lightweight, durable, and barrier properties make them ideal for a wide range of cosmetic products. Moreover, the high recyclability of aluminum minimizes its environmental impact, making it a responsible choice for conscious consumers. By embracing recycling programs and disposing of aluminum tubes responsibly, we can contribute to a more sustainable future.