Aluminium die casting is one such device that can aid in the delivery of elaborate components that can be used within damaging mechanism and for manufacturing other parts of different sorts of vehicles.

The automobile market is very effective in adopting new technologies to make their automobiles much faster and also secure at the same time. They use modern-day innovations and include devices to make sure every component utilized within cars is of best form, top quality, and also size. Aluminium die casting business makes use of trustworthy steels like aluminium as well as zinc to make specialized structures as well as elements which ultimately can be used of cars for better dependability as well as durability.

There are numerous reasons because of which the vehicle industry often tends to take on aluminium die casting as a technique of manufacturing elements like brake pads, safety belt clips, and so on. Several of these are listed here:

Safety and security and also dependability

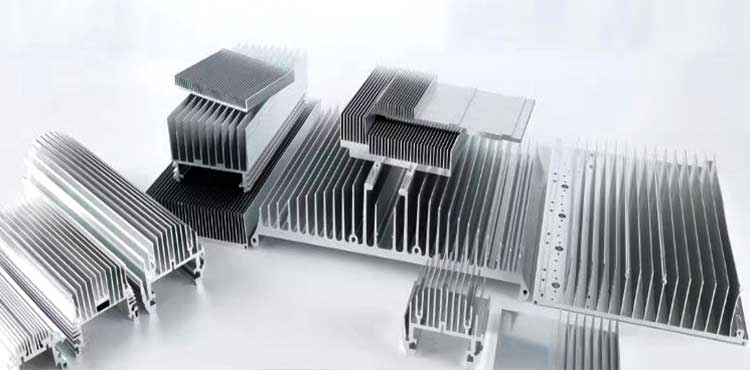

Aluminium die casting ensures the manufacturing of different kinds of elements of different designs and dimensions that are of perfect high quality and can ultimately make certain the safety of the passengers of cars. The process can help in the manufacturing of trustworthy parts that can last for a longer period without causing any kind of kind of damages to the total car. Moreover, the use of aluminium as a material for producing various parts for lorries can assist in the distribution of much better resistance to heat infection with better efficiency.

Manufacturing of lightweight parts

Die casting as a device is made use of for producing various elements within cars. Lightweight components and structures can be manufactured making use of aluminium die-casting that can aid in making the lorries a lot more effective. Vehicle suppliers can make lorries lighter as well as safer by making sure the ideal high quality of their internal as well as external components.

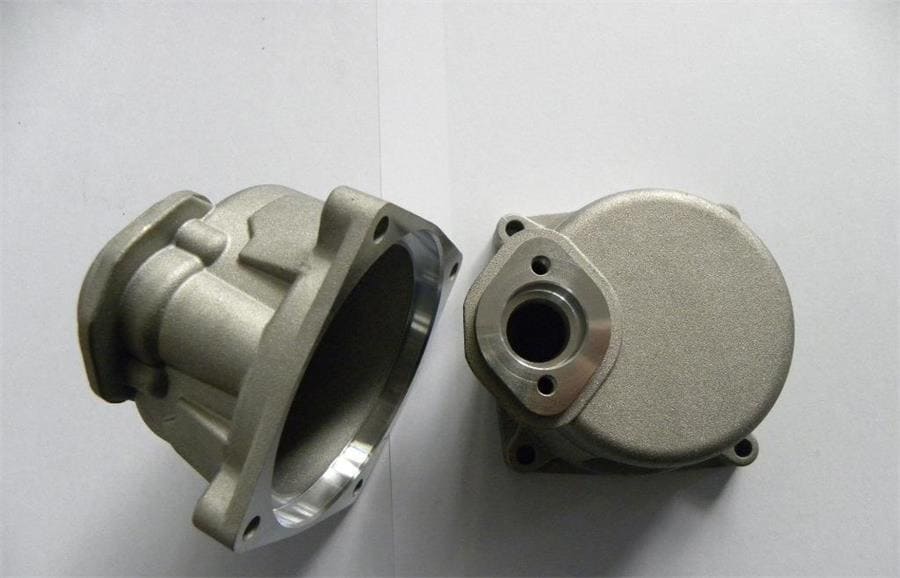

Versatility for making intricate components with far better efficiency

Aluminium die casting is taken into consideration to be an efficient device that can help in the growth of complex vehicle elements with unique designs with full effectiveness and also efficiency. Automobile parts with complex sizes and shapes can be produced and conveniently mounted within cars via an Aluminium die casting procedure.

Production of green and sustainable parts

Aluminium die-casting as a method for developing automobile elements makes sure the sustainability of the parts which are ultimately made use of within different vehicles. In addition, it is taken into consideration to be an environmentally friendly method through which vehicle components can be created without causing any kind of kind of damage to the atmosphere. Vehicle parts can be easily created without triggering any effect on the environment due to their very easy recyclable nature.

Aluminium die casting can supply optimal capability to the components which are inevitably utilized within different sorts of cars. The device is generally utilized for both internal as well as exterior parts like car framework, wipers, and also some complex components of stopping assembly of cars. Aluminium die casting business makes certain the best techniques are made use of for developing utmost components that can be used within different sorts of automobiles. The brake assembly utilizes various sorts of elements that are made using aluminium die casting device. It can assist in supplying needed safety and security to the passengers of a lorry and also the total effective capability of the complete braking mechanism.

Summary

In order to make their cars faster and at the same time safer, automotive companies often choose to use modern innovations and equipment to ensure that every component used in the car is of the best form, highest quality and size.