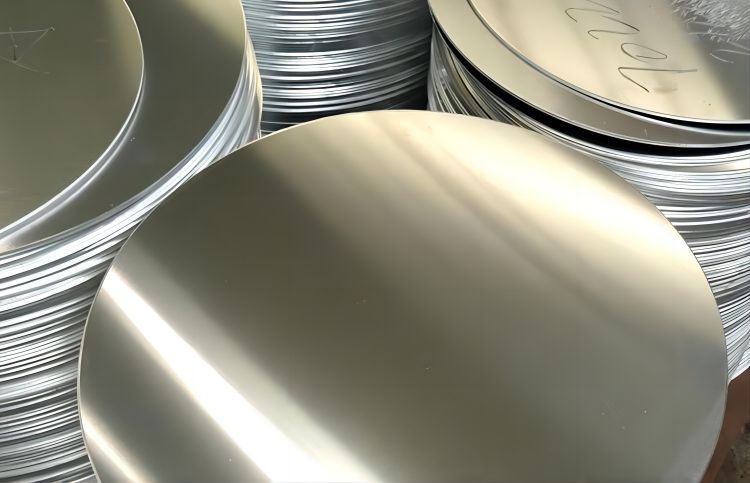

Aluminum discs circles are flat, round or shaped pieces of aluminum that are used in a variety of applications. They are made from high-quality aluminum alloy that is lightweight, strong, and corrosion-resistant. Aluminum discs circles are available in a variety of sizes, thicknesses, and finishes to meet the specific needs of each application.

Types of Aluminum Discs Circles

There are many different types of aluminum discs circles available, each with its own unique properties and applications. Some of the most common types of aluminum discs circles include:

- Round discs: Round discs are the most common type of aluminum disc. They are available in a wide range of diameters and thicknesses, and can be used for a variety of applications, such as cookware, road signs, and lighting equipment.

- Square discs: Square discs are less common than round discs, but they are still used in a variety of applications, such as electrical components and jewelry.

- Rectangular discs: Rectangular discs are also less common than round discs, but they are used in some specific applications, such as heat sinks and solar panels.

- Octagon discs: Octagon discs are a unique type of aluminum disc that has eight sides. They are used in some specific applications, such as wind turbines and musical instruments.

- Hexagon discs: Hexagon discs are another unique type of aluminum disc that has six sides. They are used in some specific applications, such as valves and gears.

- Other shapes: In addition to the common types of aluminum discs listed above, there are also many other shapes available, such as triangles, stars, and hearts. These discs are often used for decorative purposes, such as jewelry and home décor.

Uses of Aluminum Discs Circles

Aluminum discs circles have a wide variety of uses. Some of the most common applications include:

- Cookware: Aluminum discs are used to make a variety of cookware, such as frying pans, pots, and saucepans. Aluminum is a good conductor of heat, which makes it ideal for cooking. It is also lightweight and easy to clean.

- Road signs: Aluminum discs are used to make road signs. Aluminum is durable and weather-resistant, making it ideal for outdoor use. It is also reflective, which makes it easy to see at night.

- Lighting equipment: Aluminum discs are used to make a variety of lighting equipment, such as spotlights, floodlights, and streetlights. Aluminum is a good reflector of light, which makes it ideal for these applications. It is also lightweight and easy to transport.

- Electrical components: Aluminum discs are used to make a variety of electrical components, such as capacitors, transformers, and heat sinks. Aluminum is a good conductor of electricity, which makes it ideal for these applications. It is also lightweight and non-magnetic, making it ideal for use in sensitive electronic equipment.

- Medical devices: Aluminum discs are used to make a variety of medical devices, such as syringes, needles, and implants. Aluminum is biocompatible, which means that it is safe for use in the human body. It is also lightweight and easy to sterilize.

- Sporting goods: Aluminum discs are used to make a variety of sporting goods, such as frisbees, golf discs, and Frisbee golf discs. Aluminum is lightweight and durable, making it ideal for these applications. It is also easy to customize, which makes it popular for custom-made sporting goods.

- Jewelry: Aluminum discs are used to make a variety of jewelry, such as pendants, earrings, and bracelets. Aluminum is lightweight and easy to work with, making it ideal for jewelry making. It is also relatively inexpensive, which makes it a popular choice for budget-friendly jewelry.

Manufacturing Process of Aluminum Discs Circles

The manufacturing process of aluminum discs circles starts with the mining of bauxite, the ore from which aluminum is extracted. The bauxite is refined to produce alumina, which is then smelted to produce aluminum metal. The aluminum metal is then cast into ingots, which are then rolled into sheets or plates. The sheets or plates are then cut to the desired size and shape of the disc or circle. The discs and circles are then finished to the desired surface finish.

Conclusion

Aluminum discs circles are a versatile and durable material that is used in a wide variety of applications. They are lightweight, strong, corrosion-resistant, and recyclable. The manufacturing process of aluminum discs circles is relatively energy efficient and produces few emissions. Aluminum discs circles are an important part of our modern world and their use is expected to grow in the future.