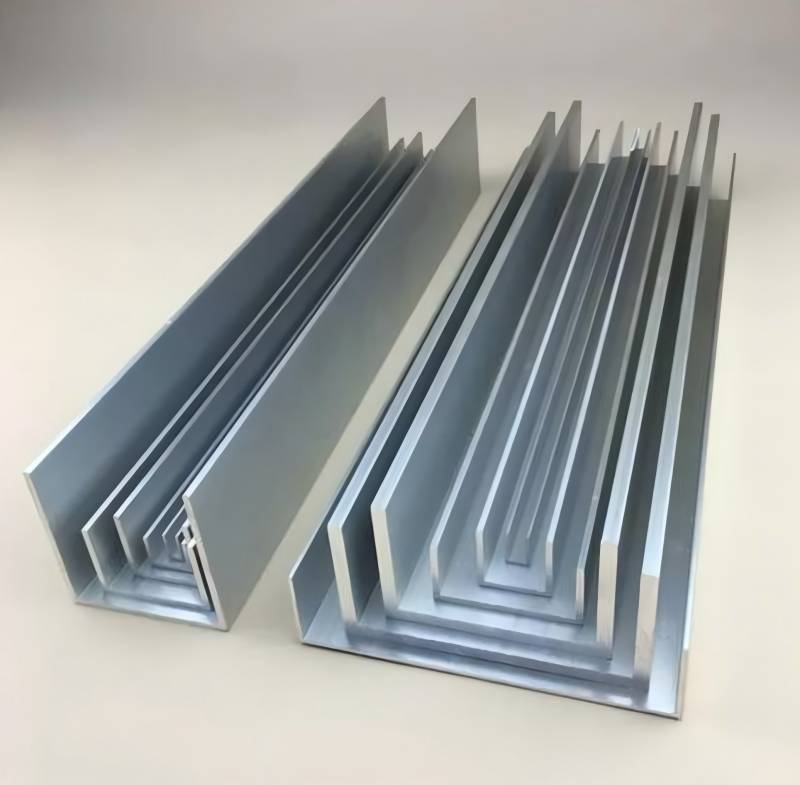

Aluminum extrusions, as a versatile metal product, have become an indispensable part of modern architecture and industrial design due to their unique properties and wide applicability. Especially in the manufacture of windows, doors, and solar panel frames, the application of aluminum extrusions not only improves the durability and aesthetics of the products, but also promotes the goals of energy efficiency and sustainable development.

Why Choose Aluminum Framing Extrusions for These Applications?

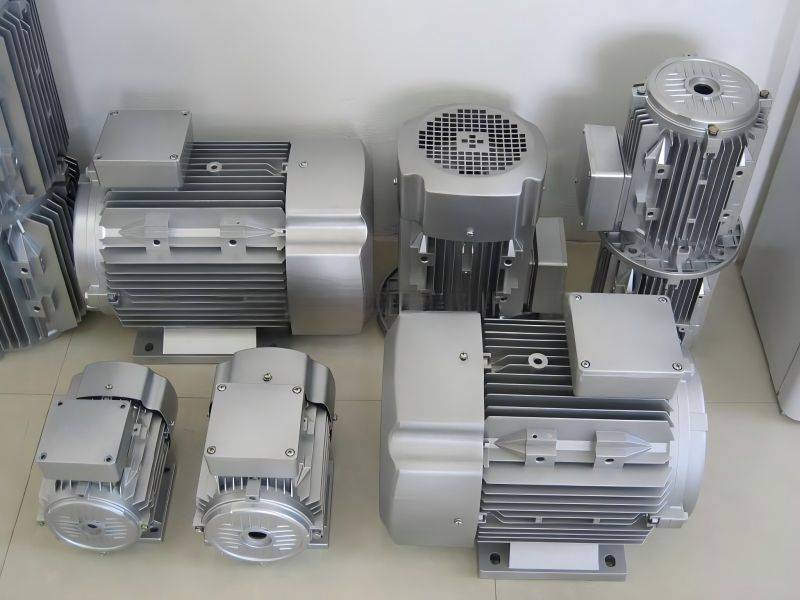

- Strength and Durability: Aluminum extrusions provide a strong, lightweight frame that can withstand the rigors of daily use and harsh environmental conditions. Unlike other materials like wood or PVC, aluminum does not warp, crack, or degrade over time, ensuring long-term performance.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that shields it from corrosion. This makes aluminum extrusions particularly well-suited for outdoor applications where they are exposed to the elements, such as in window and solar panel frames.

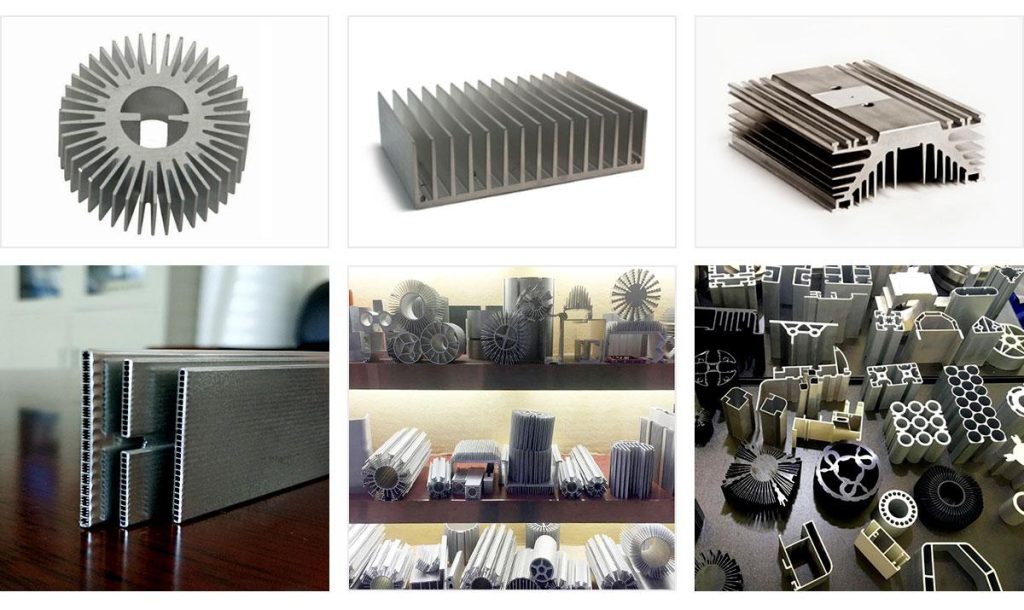

- Aesthetic Flexibility: Aluminum can be easily extruded into a wide variety of shapes and sizes, allowing for creative design possibilities. It can also be finished in numerous ways, including anodizing, powder coating, and painting, to match any architectural style.

- Sustainability: Aluminum is highly recyclable, and the recycling process requires only a fraction of the energy needed to produce new aluminum. This makes aluminum extrusions an eco-friendly choice for sustainable construction projects.

3 Main Applications of Aluminum Framing Extrusions

Aluminum extrusions have become an increasingly popular choice for window, door, and solar panel frames due to their exceptional durability, versatility, and aesthetic appeal.

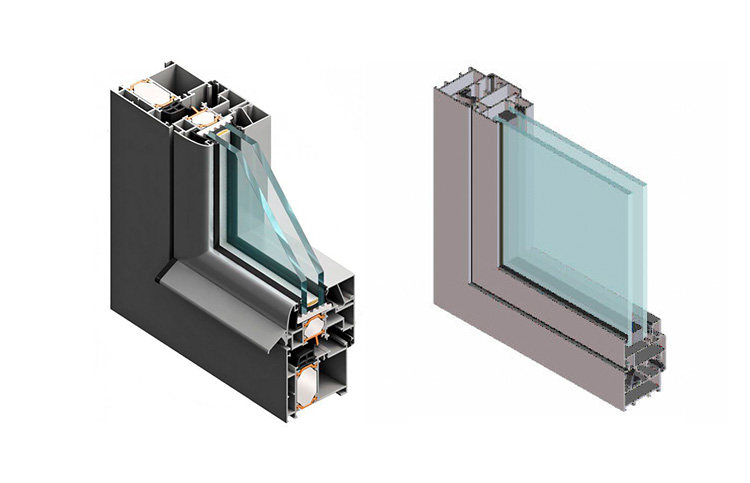

Aluminum Extrusions in Window Frames

Aluminum window frames have excellent sealing properties and can effectively isolate noise and dust. At the same time, through the application of broken bridge technology, the thermal insulation performance of windows is greatly improved, which helps to reduce the energy consumption of air conditioning and heating.

Specific Applications:

- Casement Windows: Aluminum extrusions are ideal for casement windows, providing a slim profile that maximizes glass area and enhances the view while maintaining structural integrity.

- Sliding Windows: The smooth, precise tracks made possible by aluminum extrusions ensure that sliding windows operate effortlessly and quietly.

- Fixed Windows: Aluminum’s strength allows for large fixed windows with minimal framing, offering an unobstructed view and abundant natural light.

Aluminum Extrusions in Door Frames

Aluminum door frames have good weather resistance and impact resistance, and can maintain their appearance and structural integrity even in harsh environmental conditions, extending the service life of the door.

Specific Applications:

- Entrance Doors: Aluminum extrusions provide a strong and secure frame for entrance doors, combining safety with sleek design.

- Sliding Doors: The precision and smooth operation of sliding doors are enhanced by the use of aluminum extrusions, which ensure durability and ease of movement.

- Bi-Fold Doors: Aluminum’s light weight allows for the creation of large bi-fold doors that are easy to operate and provide wide openings, perfect for connecting indoor and outdoor spaces.

- Custome Doors: Aluminum extrusions can be tailored to fit a variety of door styles, from traditional to contemporary, with various finishes to match the aesthetic of the building.

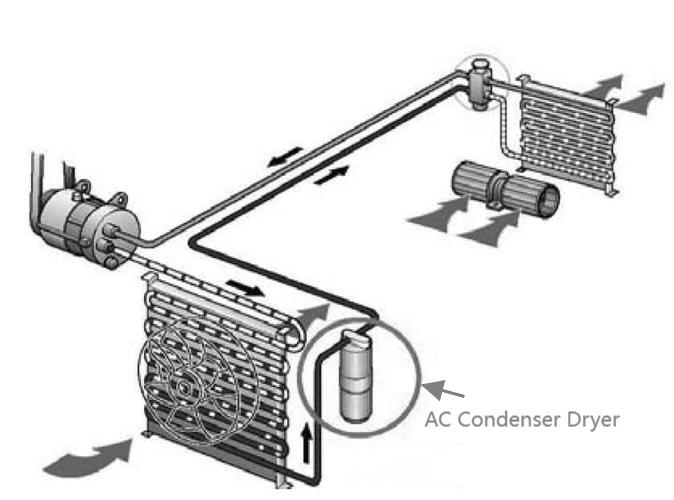

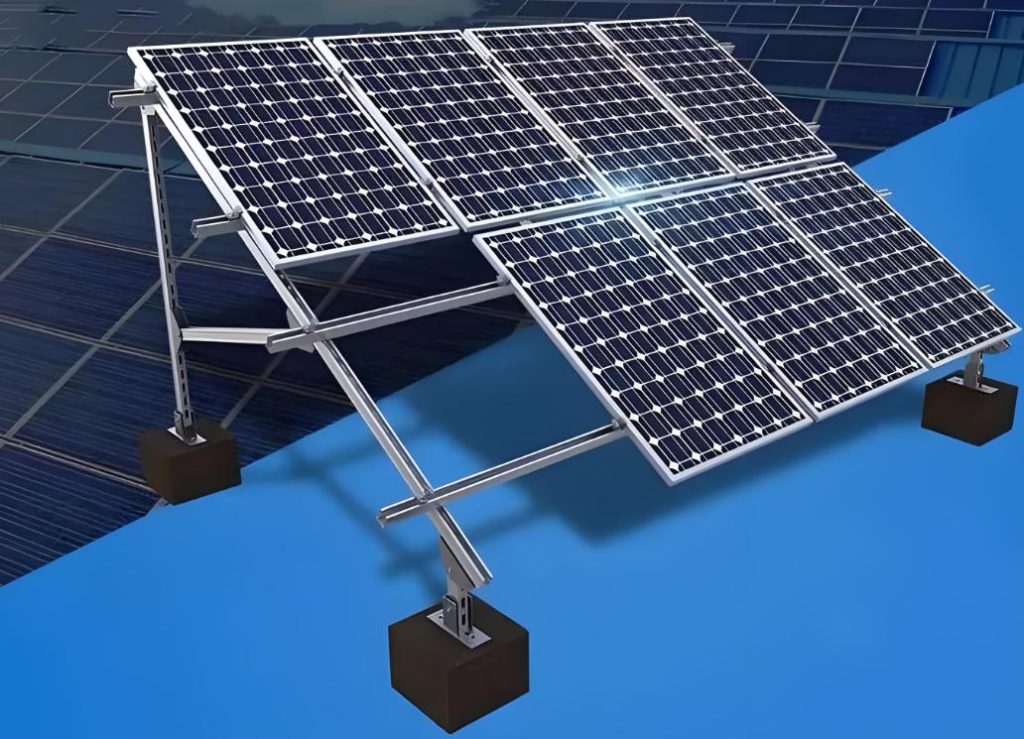

Aluminum Extrusions in Solar Panel Frames

Solar panel mounting systems require frames that are both strong and lightweight, making aluminum extrusions the material of choice. The lightweight and high-strength characteristics of aluminum frames enable solar panels to withstand various natural conditions such as wind, rain, and snow. At the same time, the conductive properties of aluminum also help to improve the efficiency of the panels and reduce energy loss.

Specific Applications:

- Rooftop Mounting Systems: Aluminum extrusions are used to create lightweight yet sturdy frames that can securely hold solar panels on rooftops without adding significant weight to the structure.

- Ground-Mounted Systems: In ground-mounted solar installations, aluminum extrusions offer a corrosion-resistant and durable solution that can withstand exposure to the elements.

- Tracking Systems: Aluminum’s flexibility allows for the creation of intricate tracking systems that follow the sun’s movement, maximizing energy capture.

How to Choose Aluminum Framing Extrusions?

Choosing the right aluminum extrusions for your project involves considering several factors:

- Application-Specific Requirements: Determine the specific demands of your application, such as load-bearing capacity, exposure to weather, and aesthetic considerations. This will guide the selection of the right aluminum alloy and extrusion profile.

- Customization Options: Aluminum extrusions can be customized in terms of shape, size, and finish. Consider the design flexibility needed for your project and choose extrusions that can be tailored to meet these needs.

- Thermal Performance: If energy efficiency is a priority, opt for aluminum extrusions with thermal breaks to minimize heat transfer and improve insulation.

- Supplier Expertise: Work with a reputable supplier who has experience in producing high-quality aluminum extrusions for your specific application. They can provide valuable insights and recommendations to ensure you get the best product for your needs.

- Environmental Impact: Consider the sustainability of the extrusions, including the use of recycled aluminum and the recyclability of the finished product at the end of its life cycle.

Aluminum extrusions are a critical component in the construction of durable and efficient window, door, and solar panel frames. Their unique combination of strength, flexibility, and resistance to environmental factors makes them the ideal choice for these applications. By understanding the benefits and choosing the right extrusions for your project, you can ensure that your frames not only perform well but also stand the test of time.