Aluminum foil, a thin, lightweight, and flexible sheet of aluminum, has become an indispensable material in modern society. Its remarkable properties, including its ability to block light, heat, and moisture, have made it a versatile tool with a wide range of applications across commercial, industrial, and consumer sectors. This article delves into the world of aluminum foil, exploring its unique characteristics, diverse uses, and the key players in its supply chain.

Commercial Aluminum Foil: A Household Staple

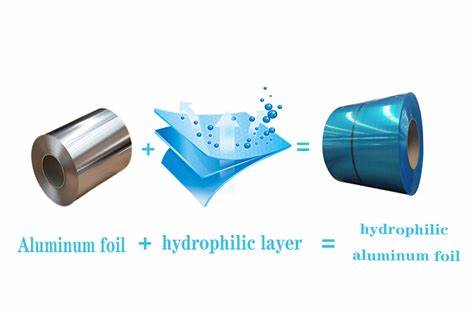

Commercial aluminum foil, widely used in households, is characterized by its thinness, typically ranging from 12 to 18 microns in thickness, making it easy to handle and mold. Its versatility stems from its ability to retain heat, prevent moisture loss, and block light. These properties make it an ideal material for food packaging and preservation, cooking and baking, electrical applications, and construction and insulation.

Applications of Commercial Aluminum Foil

- Food Packaging and Preservation: Aluminum foil’s ability to seal in moisture and prevent the transmission of light makes it an excellent material for food packaging. It is widely used to wrap meats, vegetables, and other foodstuffs, extending their shelf life and maintaining their freshness.

- Cooking and Baking: In the kitchen, aluminum foil serves a variety of purposes. It is used to line baking pans, preventing food from sticking and making cleanup easier. It also helps retain heat and moisture in dishes, ensuring even cooking and preventing dryness. Additionally, aluminum foil can be used to create makeshift covers for pots and pans, trapping heat and preventing evaporation.

- Electrical Applications: Aluminum foil’s conductivity and ability to reflect heat make it a valuable material in electrical applications. It is used as shielding material in cables and electronic devices, preventing electromagnetic interference and protecting sensitive components.

- Construction and Insulation: Aluminum foil’s reflective properties and ability to prevent heat loss make it a popular choice for construction and insulation applications. It is used in building materials, such as insulation panels and reflective barriers, to regulate temperature and improve energy efficiency.

Industrial Aluminum Foil: A Backbone of Industry

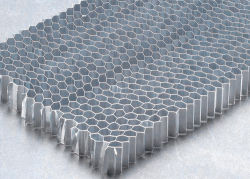

Industrial aluminum foil, characterized by its thicker gauge, ranging from 18 to 120 microns, is designed for heavy-duty applications in manufacturing and production. Its strength, durability, and ability to withstand high temperatures make it an essential material in various industries.

Applications of Industrial Aluminum Foil

- Manufacturing and Production: Industrial aluminum foil plays a crucial role in various manufacturing processes. It is used as a release liner in adhesive applications, a barrier material in packaging, and a heat retention and protection layer in industrial machinery.

- Construction and Building Materials: In the construction industry, industrial aluminum foil is used as a flexible waterproofing membrane, a thermal insulation material, and a reflective barrier in roofing and cladding applications.

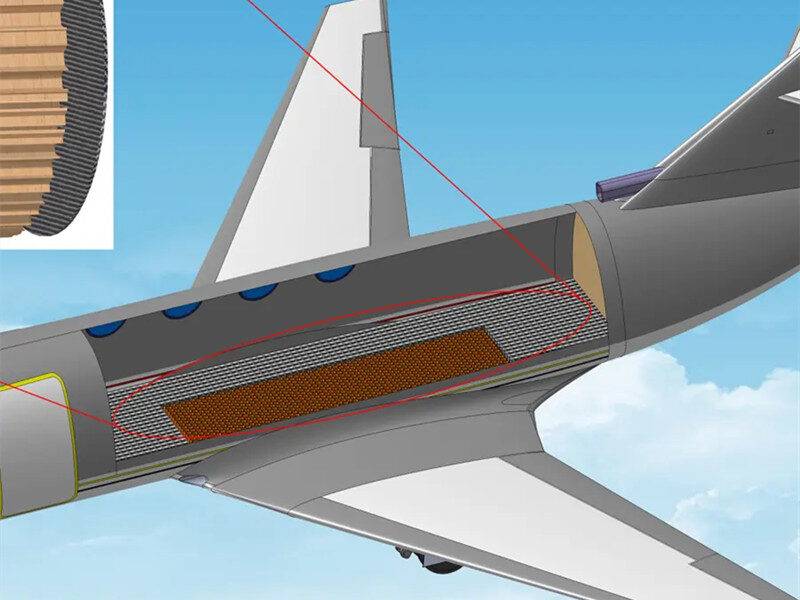

- Aerospace and Automotive Applications: Aluminum foil’s lightweight and high strength-to-weight ratio make it a valuable material in aerospace and automotive applications. It is used in aircraft structures, automotive heat shields, and electrical insulation components.

- Electronics and Packaging: In the electronics industry, aluminum foil serves as a shielding material against electromagnetic interference, a heat dissipation liner, and a protective barrier in packaging.

Aluminum Foil Suppliers: Connecting Supply and Demand

The aluminum foil supply chain involves a network of suppliers catering to different market segments. These suppliers play a critical role in ensuring the availability of aluminum foil products to meet diverse consumer and industrial needs.

Types of Aluminum Foil Suppliers

- Primary Aluminum Producers: These companies produce the raw aluminum ingots that are used to manufacture aluminum foil. They are the foundation of the aluminum foil supply chain.

- Aluminum Foil Converters: These companies specialize in converting aluminum ingots into various forms of aluminum foil, including thin commercial foil and thicker industrial foil. They process, roll, and finish aluminum to meet specific customer requirements.

- Distributors and Retailers: These companies act as intermediaries between producers and converters, distributing aluminum foil products to wholesalers, retailers, and end-users. They play a vital role in reaching a wide range of customers.

Factors to Consider When Choosing an Aluminum Foil Supplier

- Quality and Specifications of Aluminum Foil: The quality and consistency of the aluminum foil are paramount for both commercial and industrial applications. Ensuring that the foil meets the required thickness, strength, and performance standards is essential.

- Pricing and Availability: Competitive pricing and reliable supply are crucial for businesses to maintain profitability and meet customer demands. Ensuring that the supplier offers competitive prices and can consistently deliver the required quantities on time is essential.

- Customer Service and Support: Prompt and responsive customer service is vital for addressing any product or delivery issues that may arise. A supplier with excellent customer service can help businesses resolve problems quickly and maintain customer satisfaction.

Conclusion

Aluminum foil, with its unique properties and versatility, has become an indispensable material in modern society. Its applications span across commercial, industrial, and consumer sectors, making it a vital component of everyday life. The aluminum foil supply chain, comprising primary producers, converters, and distributors, ensures a steady flow of quality products to meet diverse needs. As the demand for aluminum foil continues to grow, driven by its sustainability credentials and expanding applications, the role of suppliers in connecting supply and demand becomes increasingly crucial. The future of aluminum foil holds immense promise, with advancements in technology and innovation paving the way for even more innovative and sustainable applications across various industries.