Upon exploring the practical and luxurious applications of aluminum foil, we uncover the soft and versatile side of this seemingly ordinary material. Aluminum foil, often associated with wrapping leftovers or lining baking sheets, is indeed a multifaceted marvel. In this article, let’s delve into the various roles aluminum foil plays, from being an excellent conductor of heat to serving crucial functions in insulation, flame retardation, and signal blocking in diverse fields such as electronics, power systems, and construction.

Aluminum Foil’s Crucial Role in Air Conditioning Efficiency

The primary utilization of aluminum foil in the realm of air conditioning lies in its low density and excellent thermal conductivity. Due to these properties, aluminum foil is an ideal material for manufacturing the heat exchange fins of air conditioners.

Initially, air conditioner fins were made using untreated aluminum foil, resulting in subpar performance and various inconveniences. Technological advancements led to the application of coatings, transforming the ordinary foil into a superhero for air conditioning systems. These coatings, including corrosion-resistant, lubricating, and anti-mold coatings, enhanced the foil’s performance, durability, and overall effectiveness in air conditioning applications.

Aluminum foil for air conditioning comes in two peculiar varieties: hydrophilic foil, which exhibits strong water-attracting properties, and hydrophobic foil, which repels condensation. Despite their opposing characteristics, both types serve the common purpose of facilitating the efficient dispersion of condensation, preventing water droplets from accumulating on the heat exchange fins.

Different climates and air qualities necessitate diverse solutions. Corrosion in harsh environments can significantly reduce the lifespan of ordinary foil. However, applying a corrosion-resistant coating ensures longevity and improves ventilation quality, leading to cleaner and fresher indoor air.

Everyone appreciates clean and fresh air. To prevent the growth of mold in air conditioners, an anti-mold coating is applied to aluminum foil. This innovation ensures normal air quality, eliminates abnormal mold odors, and prolongs the lifespan of air conditioning units.

For those seeking a comprehensive solution, hydrophilic foil, often referred to as the “all-in-one” solution, combines anti-corrosion, anti-mold, and odorless properties. This “superhero” foil not only enhances the lifespan of air conditioners but also improves heat exchange efficiency by 5%.

Aluminum Foil Tape: The Invisible Health Guardian

Surprisingly, aluminum foil can also take the form of tape. Aluminum foil tape harnesses the material’s electromagnetic shielding properties and finds widespread applications in electronic devices such as PDAs, laptops, and LCD monitors, where electromagnetic interference needs to be minimized. This “invisible health guardian” shields against electromagnetic disturbances, ensuring both effective signal transmission and protection against potential harm to human health.

Similar to regular transparent tape, aluminum foil tape can deform and lose adhesiveness in extreme temperatures. To address this, a solution emerged in the form of low-temperature resistant aluminum foil tape. This tape maintains its exceptional performance even in challenging weather conditions, making it suitable for applications in refrigerators, freezers, and the sealing of aluminum composite materials.

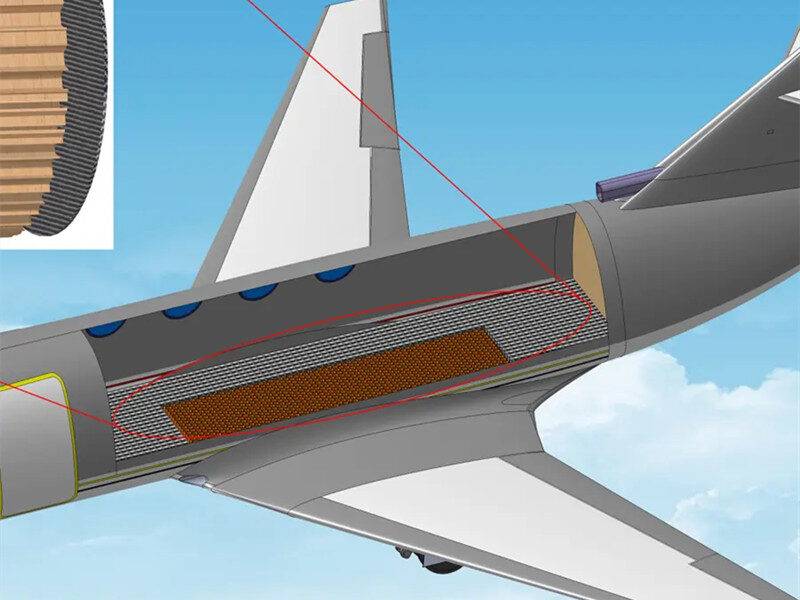

Furthermore, there is a specialized fire-resistant composite aluminum foil tape. This tape, crafted using advanced technology, consists of aluminum foil combined with glass fiber cloth and a high-performance flame-retardant acrylic adhesive. It is commonly used for sealing perforations made by insulation pins in air conditioning duct systems, providing a robust fire-resistant seal.

Carbon-Coated Aluminum Foil: Maximizing Conductivity

Despite aluminum’s inherent conductivity, ingenious minds have sought ways to optimize its performance further. The result is carbon-coated aluminum foil, where nano-conductive graphite and carbon-coated particles are uniformly applied to the foil’s surface. This “nano-armor” enhances the foil’s ability to collect microcurrents from active substances, significantly reducing resistance between positive and negative poles. This breakthrough technology maximizes the static conductivity of aluminum foil, leading to improved battery performance with reduced energy loss and enhanced overall efficiency.

Cable Foil: Shielding and Sealing with Precision

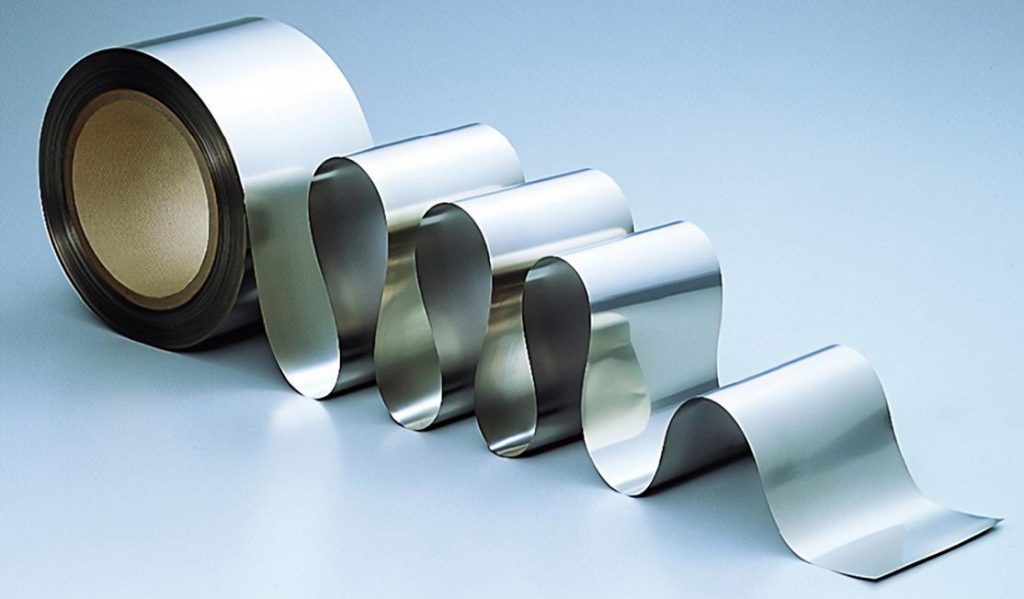

Similar to aluminum foil tape, cable foil capitalizes on aluminum foil’s electromagnetic shielding and sealing capabilities. The requirements for cable foil are relatively straightforward – low surface oil content, absence of perforations, and the addition of a plastic film coating on one or both sides. The length of the foil must strictly adhere to specifications.

After undergoing processes such as continuous casting, rolling, slitting, and annealing, aluminum foil is precisely cut into small coils according to customer specifications. These coils are then processed in cable foil composite factories, where plastic films are added to the foil, followed by further segmentation into rolls for cable manufacturers.

Decorative Foil: Elevating Aesthetics with Elegance

Transforming from the commonplace barbecue accessory to an element of grandeur, aluminum foil also finds its place in the realm of decoration. Its superior coloring capabilities and high reflectivity make it a popular choice for various decorative applications.

Used as grill foil one day and corrosion-resistant air conditioning foil the next, aluminum foil transitions effortlessly into the glamorous realm of decorative foil. Its applications range from gift box packaging to interior decoration materials for buildings and furniture. The silver-white hue of aluminum foil emits an elegant, noble, and refined atmosphere, making it a favored choice for enhancing the aesthetics of interior spaces.

In recent years, aluminum foil craft art has emerged as a novel form of interior decoration. Artists and designers use aluminum foil to create intricate and visually appealing works, adding a touch of sophistication to modern interiors.

In conclusion, aluminum foil, once regarded as a simple kitchen accessory, has evolved into a versatile material with a myriad of applications. From regulating temperatures in air conditioners to shielding electromagnetic signals and adding a touch of elegance to our surroundings, aluminum foil proves its worth in various fields. As technology continues to advance, we can only anticipate more innovative uses for this unassuming yet extraordinary material in our everyday lives.