The construction, automotive, aerospace, and electronics industries are experiencing a surge in the use of aluminum frames. This popularity stems from the inherent advantages of aluminum: lightweight, high strength, and excellent recyclability. This article delves into the expanding applications of aluminum frames in these sectors and explores the positive environmental impacts they bring.

Growing Applications of Aluminum Frames

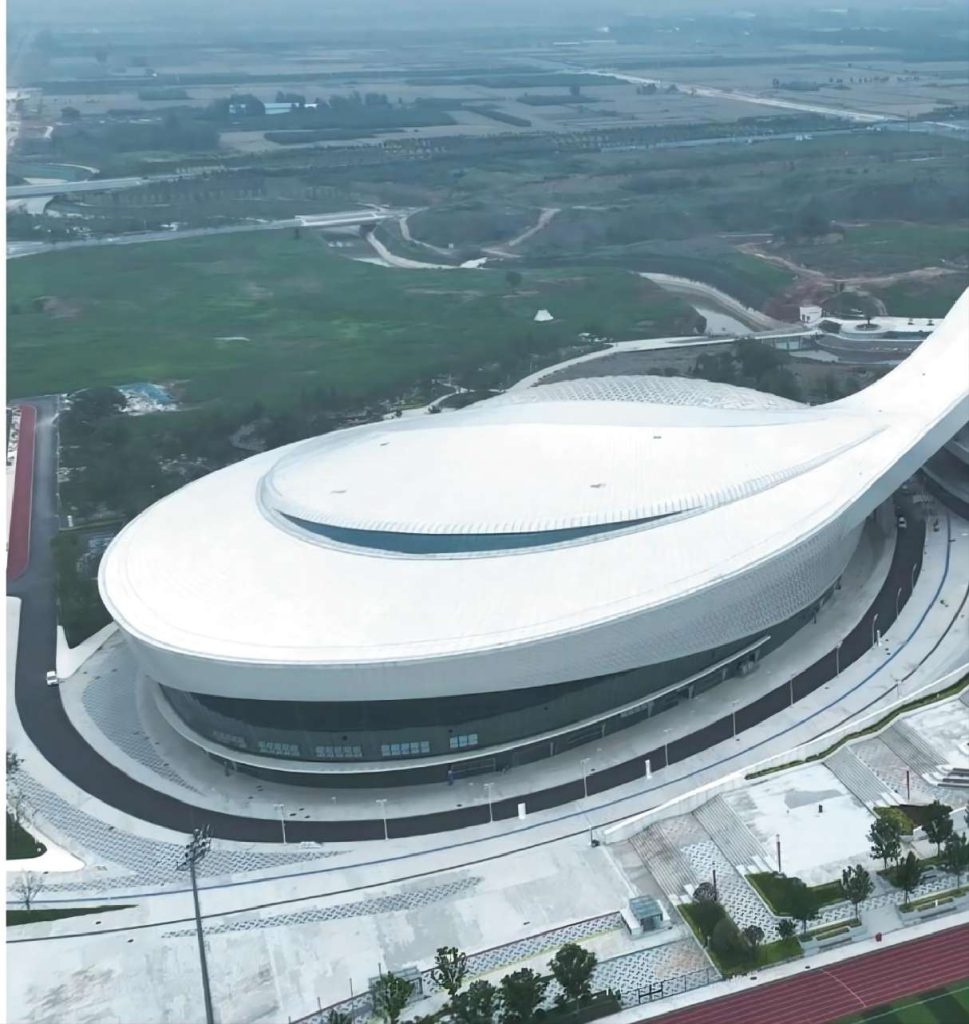

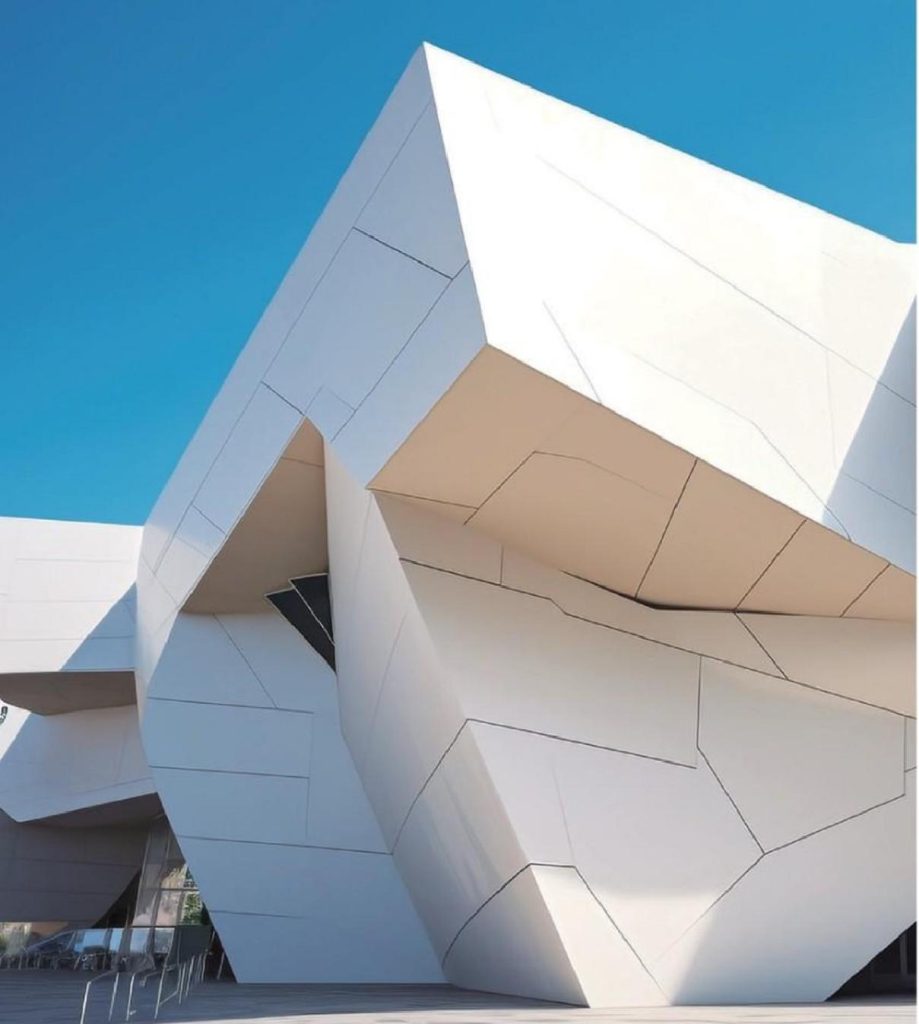

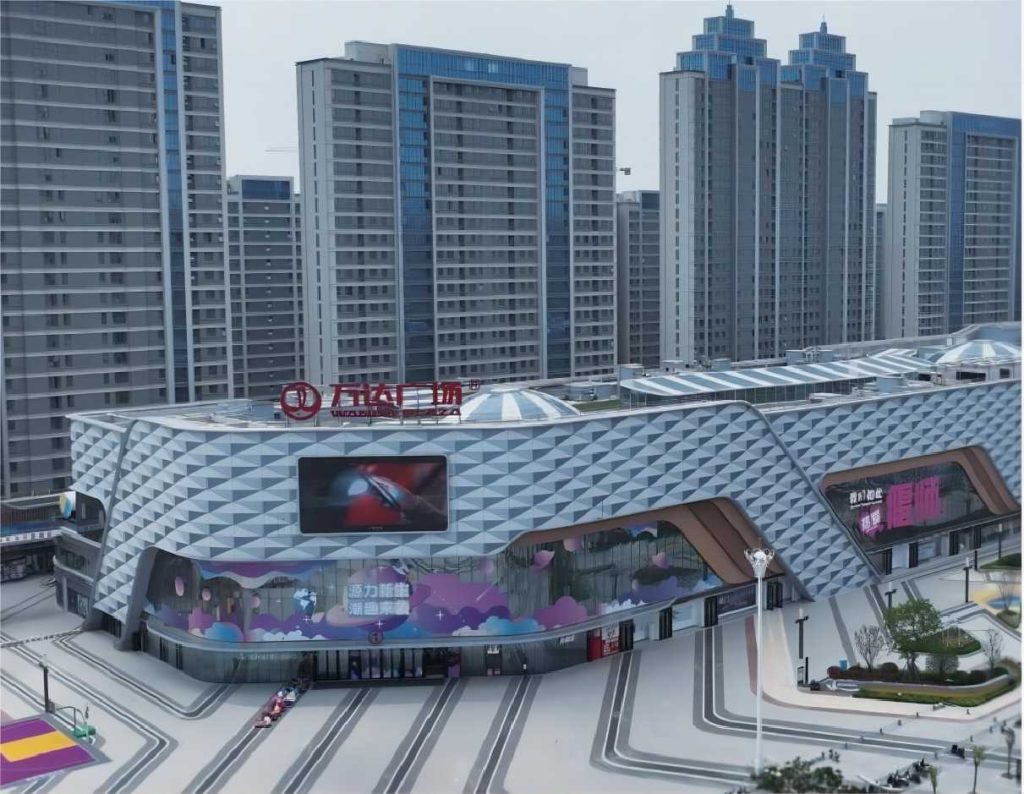

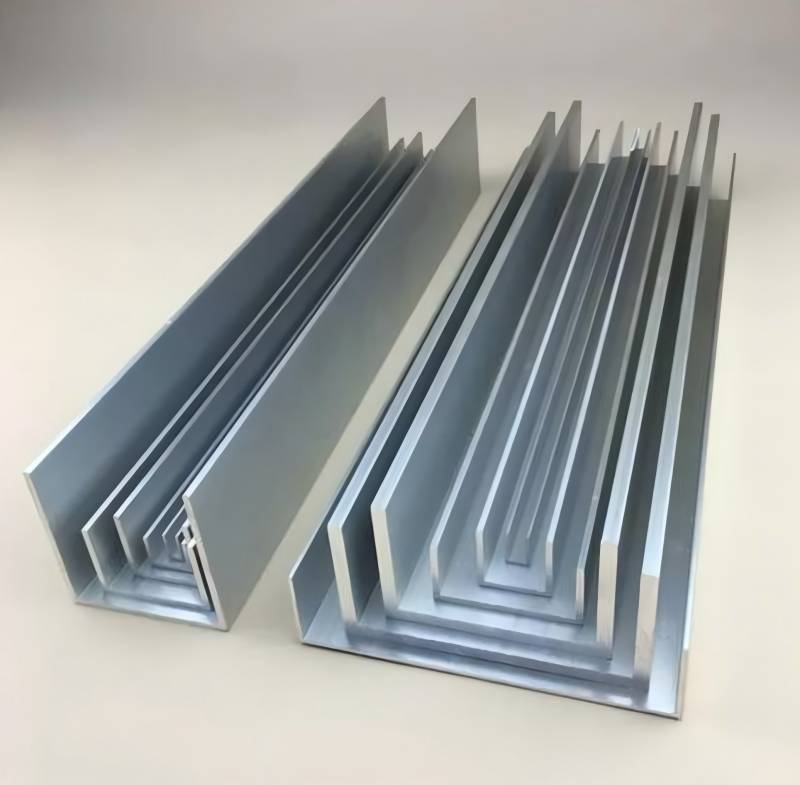

1. Aluminum Frame Construction

In the construction industry, aluminum frame construction is gaining traction, particularly in high-rise buildings, green buildings, and temporary structures. This preference is driven by two key factors: energy efficiency and recyclability.

- Energy Efficiency: Aluminum frames are significantly lighter than traditional materials like steel or concrete. This translates to a lighter building overall, which in turn reduces the energy consumption required during construction. Additionally, aluminum possesses good thermal conductivity, which can improve a building’s energy efficiency by facilitating better heat regulation and reducing the energy demands for heating and cooling.

- Recyclability: Aluminum is a highly recyclable material. At the end of their service life, aluminum frames can be effectively recycled through a remelting and remanufacturing process. This significantly reduces the need to extract and process virgin materials, minimizing the environmental impact associated with mining and initial processing.

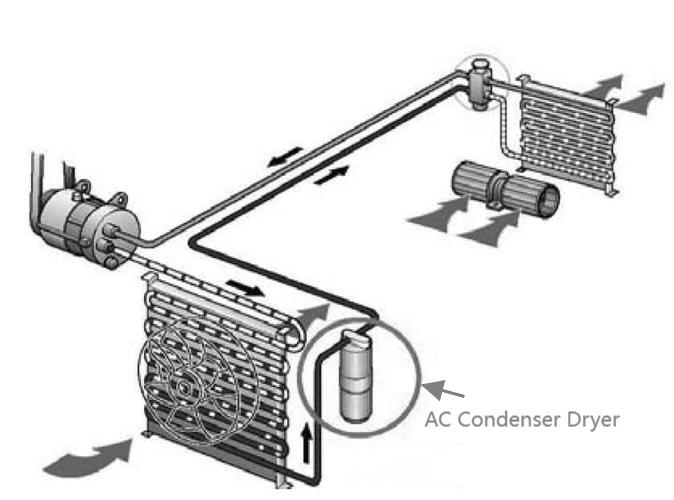

2. Aluminum Framework in the Automotive Industry

The automotive industry is embracing aluminum framework to address the growing need for improved fuel efficiency and reduced emissions. This trend is particularly evident in the development of electric vehicles and lightweight car designs.

- Weight Reduction and Fuel Economy: By replacing heavier materials with aluminum frameworks, car manufacturers can achieve significant weight reduction in vehicles. This translates to improved fuel economy, as lighter cars require less energy to move. In the context of electric vehicles, lighter frameworks can extend the driving range on a single charge.

- Lightweight Design: The push for lightweight car designs aligns perfectly with the properties of aluminum. Aluminum frameworks enable car manufacturers to create vehicles that are both strong and lightweight, enhancing overall performance and contributing to fuel efficiency goals.

3. Aluminum Frameworks Take Flight in Aerospace

The aerospace industry prioritizes high-strength, low-weight materials for aircraft and spacecraft manufacturing. Aluminum frameworks excel in this domain, offering the perfect combination of these crucial properties.

- Enhanced Fuel Efficiency: Similar to the automotive industry, the use of aluminum frameworks in aircraft construction leads to significant weight reduction. This translates to improved fuel efficiency, which is paramount for airlines aiming to reduce operational costs and environmental impact. Additionally, lighter aircraft can carry heavier payloads, increasing their operational versatility.

- Payload Capacity: By utilizing aluminum frameworks, aerospace engineers can design aircraft with a higher payload capacity without compromising on overall weight. This allows for carrying more passengers or cargo, enhancing the efficiency and profitability of air travel.

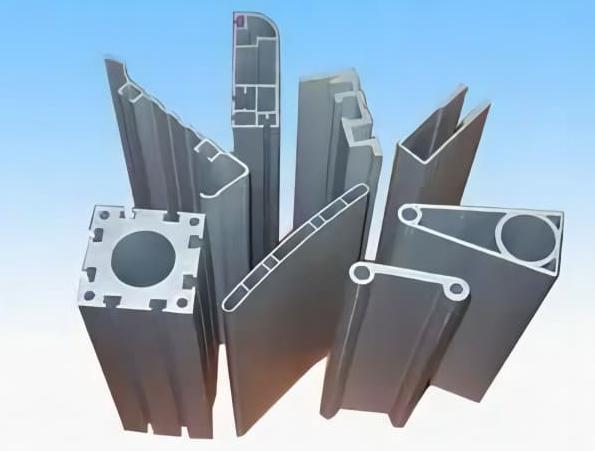

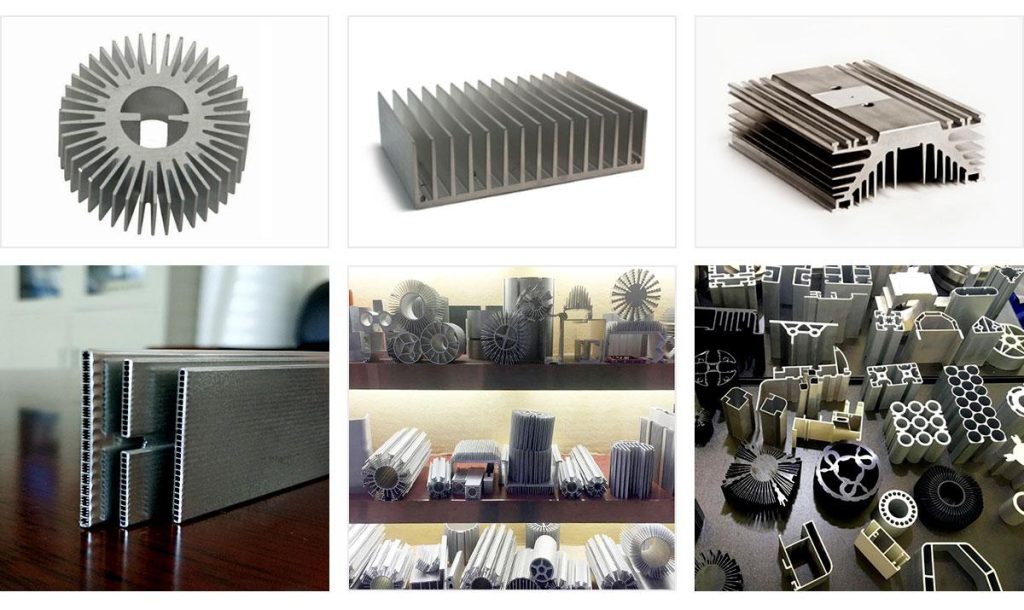

4. Aluminum Frames Power Up the Electronics Industry

The rise of 5G technology and the ever-increasing demand for lightweight, durable materials in consumer electronics have fueled the use of aluminum frames in smartphones, tablets, and other portable devices.

- Lightweight and Durable: Aluminum frames provide the perfect balance of lightness and durability, making them ideal for portable electronic devices. This combination ensures the devices are easy to carry while remaining robust enough to withstand everyday use.

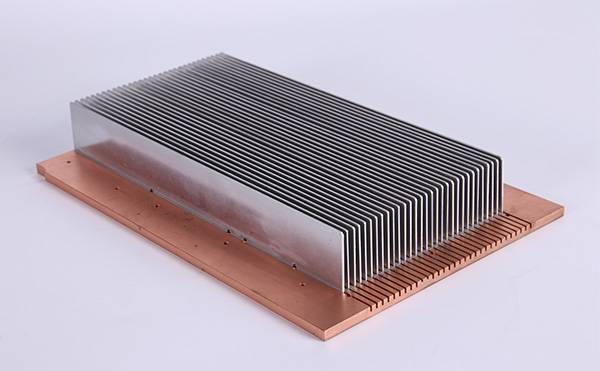

- Supporting 5G Technology: The development of 5G technology requires materials that can handle the increased processing power and heat generation associated with these advanced devices. Aluminum frames offer a good solution, as they can effectively dissipate heat while remaining lightweight and structurally sound.

The Environmental Benefits of Aluminum Frames

The growing adoption of aluminum frames across various industries extends beyond performance benefits. These lightweight frameworks offer significant environmental advantages.

1. Energy Efficiency and Emissions Reduction

Aluminum frames contribute to energy efficiency and emissions reduction in several ways:

- Construction: As mentioned earlier, aluminum frame construction reduces building weight, leading to lower energy consumption during construction and improved building energy efficiency throughout its lifespan.

- Automotive: The use of aluminum frameworks in cars leads to weight reduction, which translates to improved fuel economy and reduced tailpipe emissions. This is a crucial factor in the fight against climate change and the need to minimize greenhouse gas emissions.

- Aerospace: Aluminum frameworks in aircraft construction enhance fuel efficiency, resulting in a lower carbon footprint per flight. This contributes to a cleaner and more sustainable aviation industry.

2. Resource Recycling

Aluminum is a highly recyclable material, offering significant environmental benefits:

- High Recyclability: At the end of their useful life, aluminum frames can be effectively recycled. The recycling process involves remelting and remanufacturing the aluminum, significantly reducing the need to extract and process virgin materials. This translates to a smaller environmental footprint associated with mining and initial processing.

- Energy-Efficient Recycling: The recycling process for aluminum requires significantly less energy compared to producing new aluminum from scratch. This translates to lower overall energy consumption throughout the lifecycle of aluminum frames and minimizes environmental pollution associated with energy production.

3. Eco-Friendly Material

Aluminum itself boasts eco-friendly properties that contribute to a cleaner environment:

- Reduced Hazardous Emissions: The production of aluminum frames generates relatively low levels of harmful pollutants compared to other materials. Emissions like sulfur dioxide and nitrogen oxides, which can contribute to acid rain and smog, are significantly reduced with aluminum usage.

- Natural Corrosion Resistance: Aluminum possesses a natural resistance to corrosion. This eliminates the need for extensive use of protective coatings on aluminum frames. This reduction in coatings translates to a lower risk of environmental harm associated with the production and disposal of these coatings.

4. Green Buildings and Sustainable Development

Aluminum frame construction aligns perfectly with the principles of green building and sustainable development:

- Recyclability and Lightweight Properties: As discussed earlier, the high recyclability and lightweight nature of aluminum frames contribute to sustainable building practices. These properties help minimize construction waste, reduce the overall environmental impact of buildings, and enhance their energy efficiency.

5. Clean Energy Infrastructure

The growing focus on renewable energy sources like solar and wind power is creating new opportunities for aluminum frames:

- Renewable Energy Applications: Aluminum frames are increasingly being used in wind turbine towers and solar PV mounting structures. This widespread adoption supports the expansion of clean energy infrastructure, which in turn reduces reliance on fossil fuels and contributes to a cleaner environment.

Conclusion

The rise of aluminum frames signifies a positive shift across various industries. These lightweight, high-strength frameworks not only enhance product performance and efficiency but also contribute significantly to environmental protection and sustainable development. By reducing resource consumption, minimizing pollutant emissions, and promoting clean energy adoption, aluminum frames are paving the way for a more sustainable future. As technology continues to evolve and environmental concerns gain further prominence, we can expect to see even wider applications of aluminum frames across various sectors, further solidifying their role in building a cleaner and more sustainable world.