The automotive industry is undergoing a significant transformation, driven by the need for improved fuel efficiency, reduced emissions, and the rise of electric vehicles (EVs). A key component in achieving these goals is efficient thermal management. Enter aluminum heat sinks, which are rapidly increasing their presence in vehicles due to their superior properties.

This article explores the penetration rate of aluminum heat sinks in the automotive industry, analyzing the factors driving their adoption and their future outlook.

Why Aluminum Heat Sinks More Popular

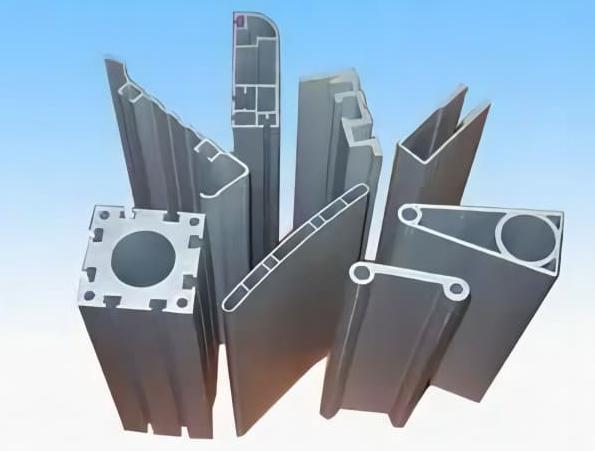

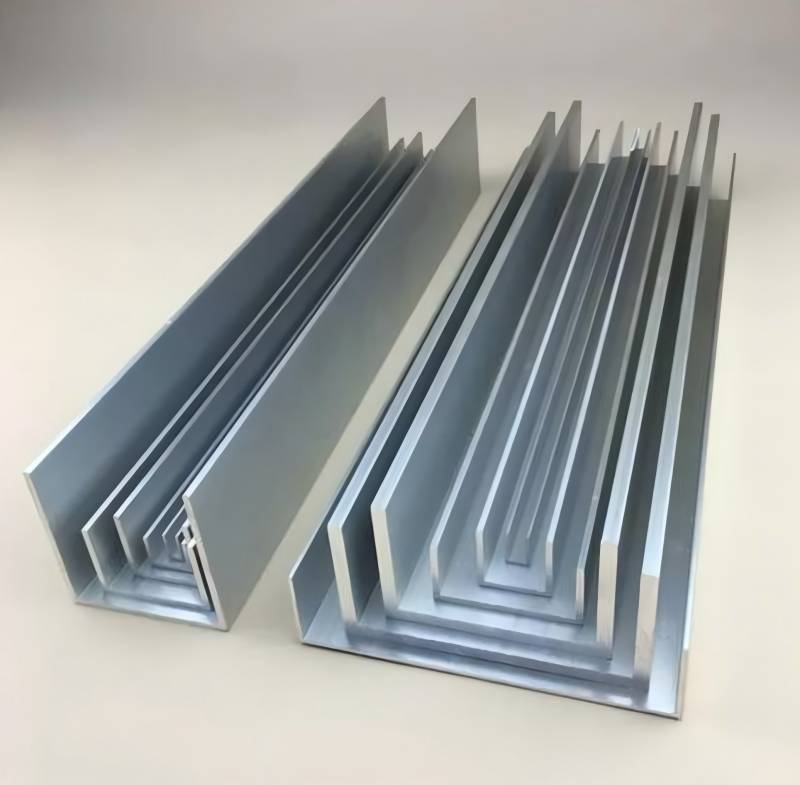

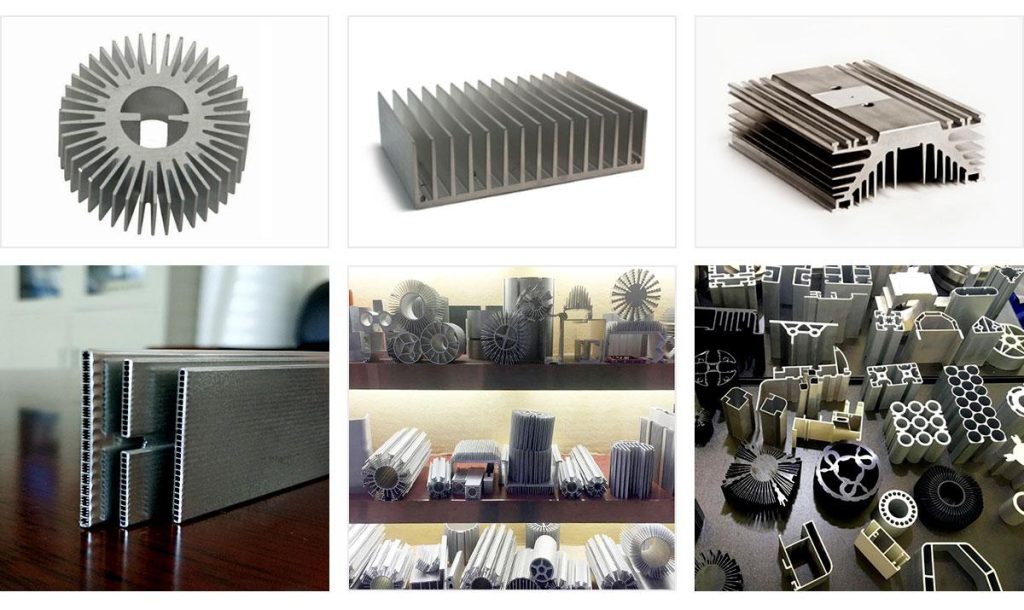

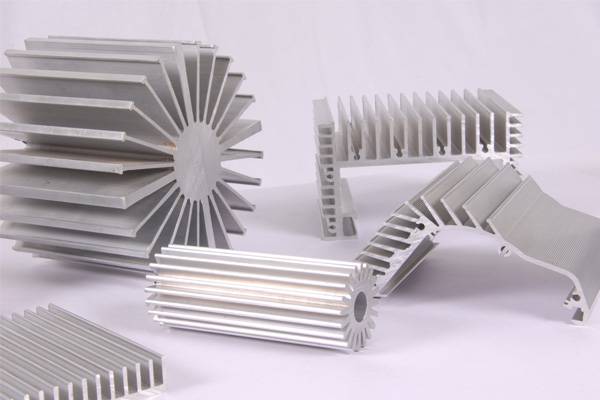

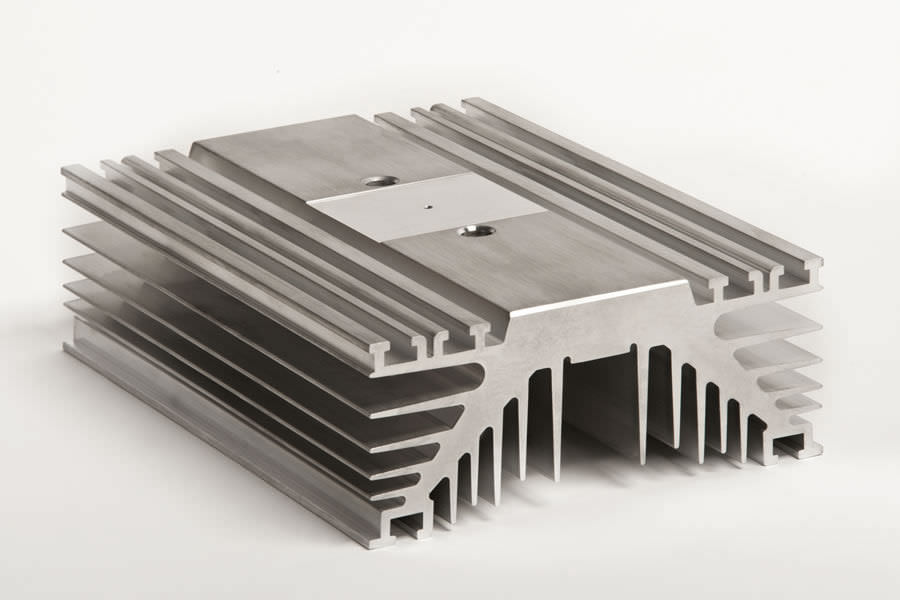

An aluminum heat sink is a passive cooling device that absorbs heat from a source and transfers it to the surrounding air. They are typically constructed from aluminum fins attached to a base plate, maximizing surface area for heat exchange. Compared to traditional copper heat sinks, aluminum offers several advantages:

- Lightweight: Aluminum is significantly lighter than copper, with a density of roughly one-third that of copper. In the automotive industry, where every gram counts for fuel efficiency, this weight reduction translates to real-world benefits.

- Efficient Heat Dissipation: While copper boasts slightly better thermal conductivity than aluminum, the difference is often negligible in practical applications. Aluminum’s high conductivity combined with its large surface area design allows for effective heat dissipation in automotive applications.

- Corrosion Resistance: Aluminum naturally forms a thin oxide layer that protects it from corrosion. This is crucial in the harsh automotive environment, where exposure to moisture and road salts can accelerate component degradation.

These advantages have propelled aluminum heat sinks to the forefront of automotive thermal management solutions.

Rising Penetration Rate of Aluminum Heat Sinks

The penetration rate of aluminum heat sinks, expressed as the percentage of vehicles utilizing this technology, has witnessed a steady rise in recent years. As of 2021, global figures indicate an overall penetration rate of approximately 70% across the automotive industry. This figure is further broken down by vehicle type, with passenger cars boasting a higher penetration rate of around 80% compared to commercial vehicles, which sit at roughly 50%. Analysts predict this trend will continue, with projections suggesting that the global penetration rate for aluminum heat sinks in automobiles will surpass 80% by 2025.

Factors Driving Aluminum Heat Sink Adoption

Several key factors are contributing to the rising adoption rate of aluminum heat sinks in automobiles:

- Demand for Lightweight Vehicles: Stringent fuel efficiency regulations and consumer preferences for eco-friendly vehicles are driving the automotive industry towards lightweight materials. The weight reduction offered by aluminum heat sinks, compared to copper counterparts, plays a vital role in achieving these goals. Every kilogram saved translates to improved fuel economy and reduced emissions.

- Rapid Growth of Electric Vehicles: The rapid adoption of EVs presents unique thermal management challenges. Electric motors and battery packs generate significant heat that needs efficient dissipation to ensure optimal performance and longevity. Aluminum heat sinks, with their excellent heat transfer capabilities, are ideally suited for this purpose. Furthermore, the lighter weight of aluminum heat sinks contributes to the overall weight reduction of EVs, maximizing their range and efficiency.

- Advancements in Automotive Manufacturing: Technological advancements in the automotive manufacturing sector have played a crucial role in making aluminum heat sinks a more viable option. Improved manufacturing processes have led to a decrease in the production cost of aluminum heat sinks, enhancing their cost-effectiveness compared to traditional copper solutions. Additionally, advancements in joining technologies have facilitated the integration of aluminum heat sinks into complex automotive components.

The Future of Aluminum Heat Sinks in Automotive Applications

The future of aluminum heat sinks in the automotive industry appears bright. The increasing demand for lightweight vehicles and the rapid growth of the EV market are expected to continue to drive the adoption of these efficient thermal management solutions. Furthermore, ongoing advancements in manufacturing processes and materials science hold promise for even lighter and more efficient aluminum heat sink designs.

Regional Variations in Penetration Rate

The current penetration rate of aluminum heat sinks in the automotive industry varies across different regions. Here’s a snapshot of some key markets:

- China: China, the world’s largest automotive market, has witnessed a significant increase in the adoption of aluminum heat sinks. The penetration rate in China was estimated to be around 65% in 2021, with projections indicating a rise to over 75% by 2025. This growth is closely linked to China’s focus on fuel efficiency regulations and the burgeoning EV market.

- United States: The United States, another major automotive player, has a higher current penetration rate for aluminum heat sinks compared to China. Estimates suggest a penetration rate of around 75% in 2021, with projections of further growth to over 80% by 2025. The focus on environmental regulations and consumer demand for fuel-efficient vehicles contribute to this trend.

- Europe: Europe is a leader in terms of stringent fuel efficiency regulations and has a well-established electric vehicle market. Consequently, the penetration rate of aluminum heat sinks in European automobiles is high. Estimates suggest a penetration rate of approximately 70% in 2021, with projections of reaching 75% or higher by 2025. European car manufacturers are at the forefront of technological innovation, and the adoption of lightweight and efficient aluminum heat sinks reflects this commitment.

Emerging Applications of Aluminum Heat Sinks

While penetration rate is a key metric, it doesn’t capture the full picture of aluminum heat sink adoption in the automotive industry. Beyond their widespread use in traditional engine cooling systems, aluminum heat sinks are finding applications in a growing number of automotive components:

- Power Electronics: The increasing complexity of automotive electrical systems, driven by features like advanced driver-assistance systems (ADAS) and hybrid powertrains, necessitates efficient thermal management for power electronics. Aluminum heat sinks offer a lightweight and cost-effective solution for cooling these components, ensuring optimal performance and reliability.

- Battery Thermal Management Systems (BTMS): As mentioned earlier, efficient thermal management is critical for EV battery packs. Aluminum heat sinks can be integrated into BTMS designs to maintain optimal battery temperature, which maximizes battery life and performance. Furthermore, the lightweight nature of aluminum contributes to the overall weight reduction of EVs.

- Transmission and Drivetrain Components: Transmissions and other drivetrain components generate significant heat during operation. Aluminum heat sinks can be strategically placed to dissipate this heat, improving component longevity and overall vehicle performance.

The expanding use of aluminum heat sinks in these diverse applications highlights their versatility and growing importance in the automotive thermal management landscape.

Conclusion

Aluminum heat sinks have become a cornerstone of automotive thermal management solutions. Their combination of lightweight design, efficient heat dissipation, and cost-effectiveness makes them the preferred choice for a wide range of applications. As the automotive industry continues its focus on fuel efficiency, electric vehicle development, and lightweight materials, the penetration rate of aluminum heat sinks is expected to climb even higher. With ongoing advancements in manufacturing techniques and materials science, aluminum heat sinks are poised to play an even greater role in the future of automotive thermal management.

With the ever-evolving landscape of automotive thermal management, a variety of aluminum heat sink solutions are available from numerous manufacturers. Consulting with a qualified supplier and considering factors like application, performance requirements, and budget will ensure the selection of the most suitable aluminum heat sink for your specific automotive application. CHAL is a good choice, please please don’t hesitate to contact us.