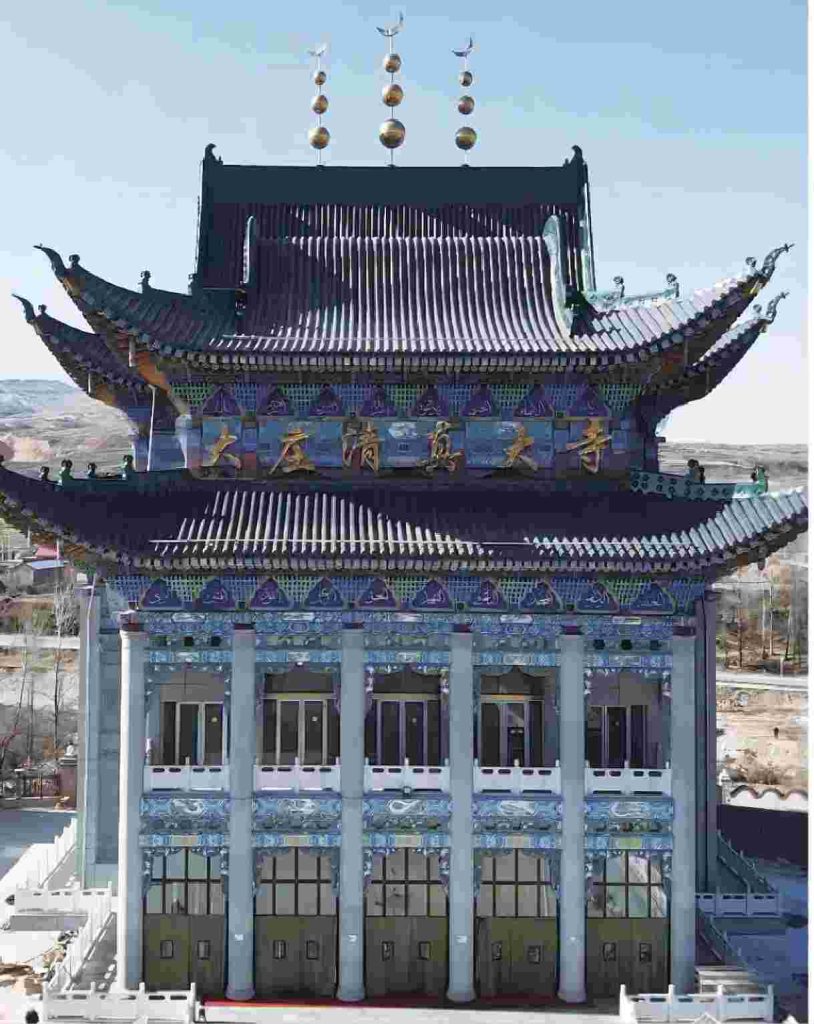

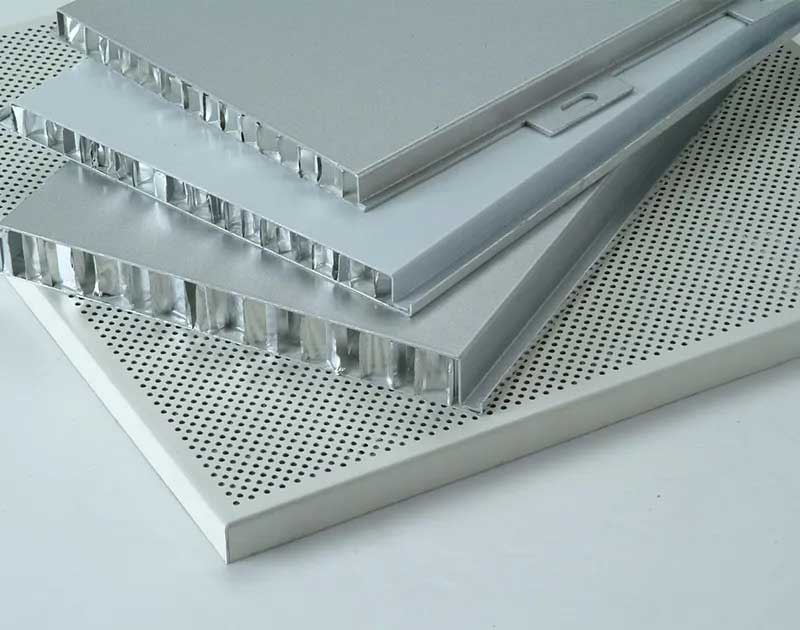

Aluminum honeycomb panels are widely recognized for their lightweight, durable, and aesthetically pleasing properties. These panels are extensively used in construction, interior design, transportation, and other industries. Their strength-to-weight ratio, flatness, and resistance to corrosion make them ideal for applications like facades, ceilings, partitions, and more. Proper installation is crucial to ensure that aluminum honeycomb panels perform optimally and maintain their visual appeal.

This article will discuss the various installation methods for aluminum honeycomb panels and the key considerations to ensure a successful and long-lasting application.

Installation Methods for Aluminum Honeycomb Panels

Several methods are commonly used to install aluminum honeycomb panels, depending on the specific application and environmental conditions. Below are the most prevalent techniques:

1. Dry Hanging Method

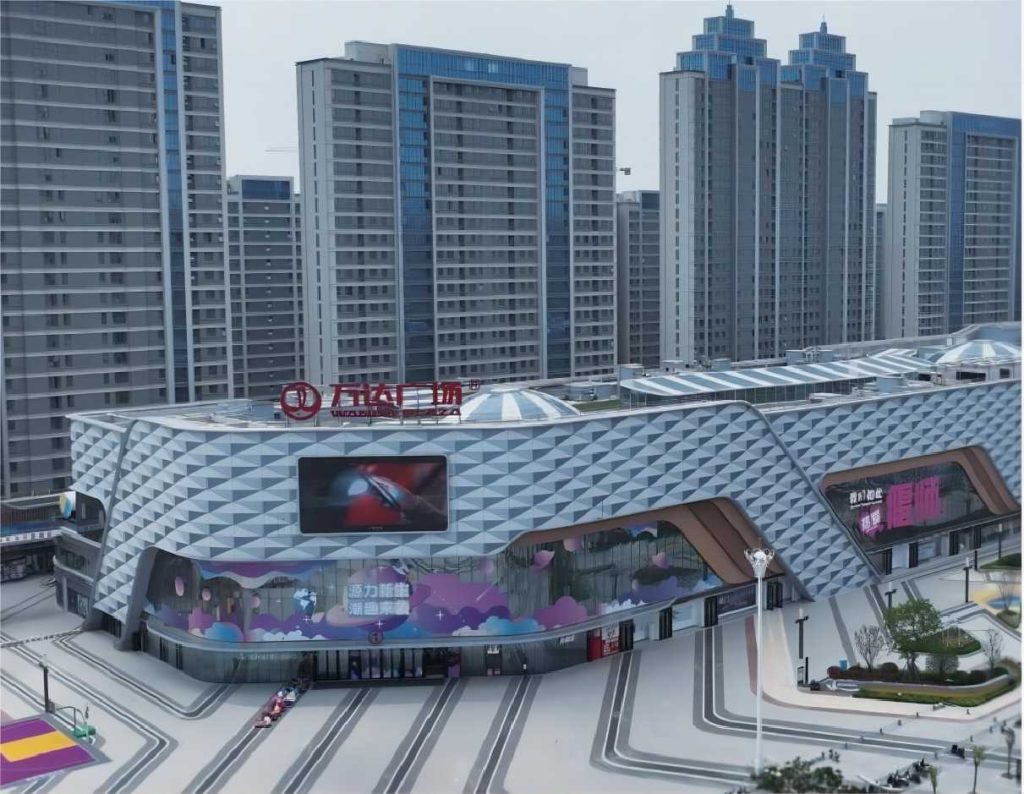

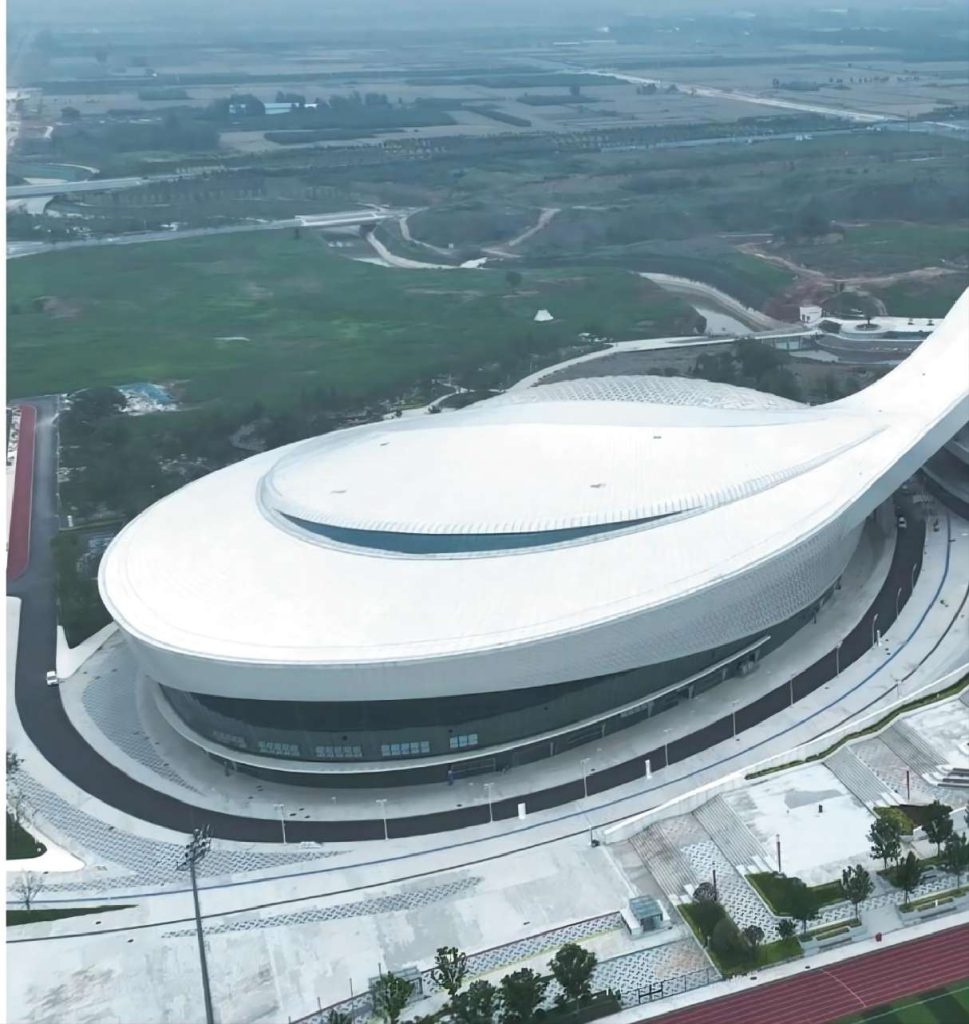

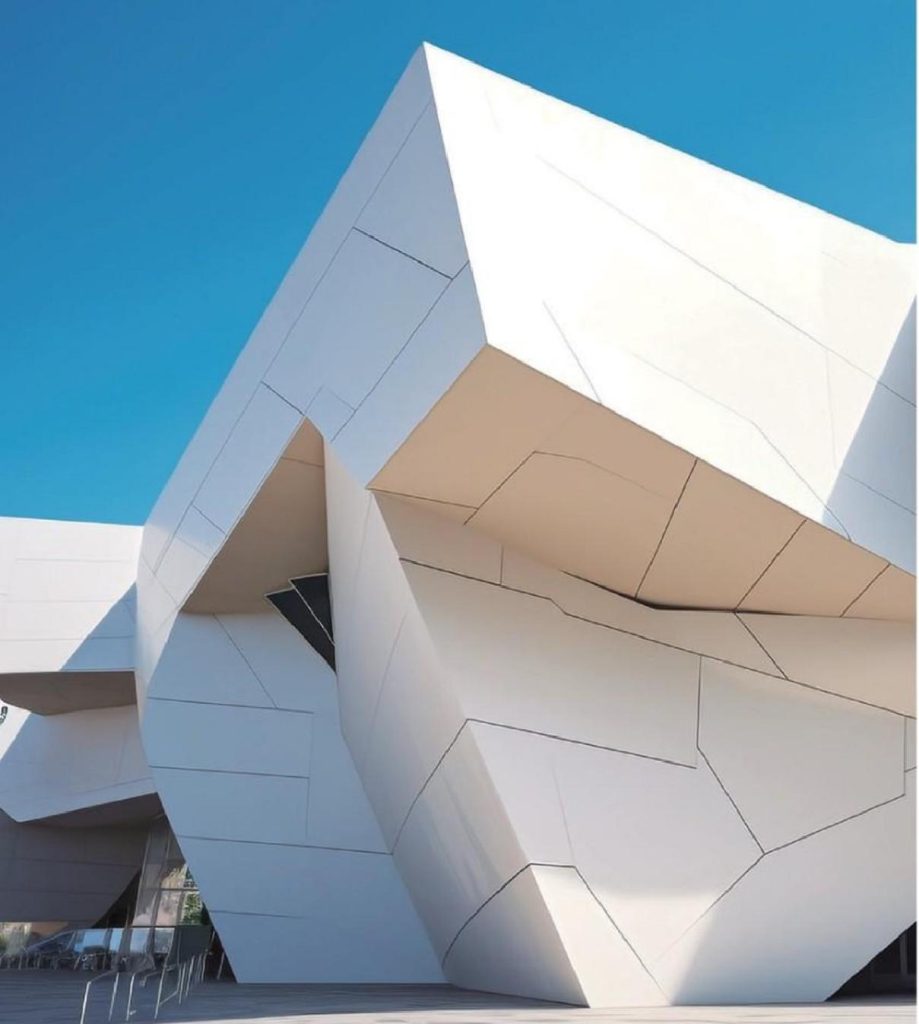

The dry hanging method is widely employed for exterior cladding applications, such as building facades or curtain walls.

Steps:

- Prepare the Primary Structure: Install main support structures, such as primary brackets or main beams, using expansion bolts or chemical anchors. These must be securely attached to the existing wall or framework.

- Attach Secondary Structures: Install secondary structures, typically aluminum alloy subframes, onto the primary supports. Adjust their alignment for levelness and plumb.

- Fix the Panels: Use specialized fasteners, such as clips or bolts, to securely attach the aluminum honeycomb panels to the subframe. Leave sufficient expansion gaps between panels to accommodate thermal movement.

Advantages:

- High precision and stability.

- Aesthetic and seamless appearance due to uniform panel spacing.

- Suitable for large-scale installations.

2. Adhesive Bonding Method

This method is ideal for interior walls, lightweight structures, or situations where adhesive strength is sufficient to hold the panels.

Steps:

- Surface Preparation: Ensure the wall surface and panel backs are clean, smooth, and dry.

- Apply Adhesive: Use a high-quality structural adhesive or two-part epoxy resin. Apply it evenly on both the panel’s backside and the substrate.

- Position the Panels: Carefully press the aluminum honeycomb panels onto the wall surface, ensuring alignment with the design layout. Use a roller to apply uniform pressure and eliminate air bubbles.

Advantages:

- Cost-effective and easy to apply.

- Creates a smooth surface with no visible fasteners.

- Suitable for indoor applications where strength requirements are moderate.

3. Suspended Framework Method (for Ceilings)

This method is frequently used for suspended ceilings in commercial buildings, exhibition halls, and public spaces.

Steps:

- Install Main Suspension System: Use suspension rods and anchors to secure the main framework to the structural ceiling. Ensure the framework is level.

- Add Secondary Framework: Fix secondary frames or grid structures to the primary suspension system.

- Attach Panels: Secure the aluminum honeycomb panels to the framework using screws or clips, depending on the design. Ensure proper alignment and spacing between panels.

Advantages:

- Robust and durable structure.

- Easy to replace individual panels for maintenance.

- Suitable for large-span ceilings.

4. Snap-Fit or Clamping Installation

This approach is common for modern facade systems, partitions, and modular ceiling systems, offering a clean and professional finish.

Steps:

- Install Guide Rails or Tracks: Attach metal tracks to the primary support structure.

- Align Panels: Slide or snap the aluminum honeycomb panels into the guide rails. Use clamps or locking mechanisms to hold them in place securely.

- Check Stability: Ensure that all panels are correctly aligned and firmly held in the system.

Advantages:

- Quick and straightforward assembly.

- Allows for easy disassembly and replacement.

- Ideal for projects requiring modular designs.

Key Considerations for Installing Aluminum Honeycomb Panels

To ensure the durability, safety, and aesthetic quality of aluminum honeycomb panels, several important factors must be considered during installation:

1. Surface and Material Preparation

- Panel Quality Check: Inspect all panels for defects such as scratches, dents, or coating inconsistencies before installation. Only use undamaged panels.

- Substrate or Frame Condition: The surface or framework must be level, stable, and capable of bearing the load.

- Cleaning: Ensure surfaces are free from dust, grease, or moisture that could interfere with adhesion or fitting.

2. Precision in Measurements

- Accurate Panel Dimensions: Verify the dimensions of each panel to ensure they fit according to the design plan.

- Consistent Spacing: Maintain uniform gaps between panels for thermal expansion and contraction, especially for outdoor installations.

- Alignment: Use tools like laser levels or plumb lines to check for straight and even panel placement.

3. Environmental Factors

- Temperature: Install panels in an environment where the temperature is above 5°C. Extremely low temperatures can affect the curing of adhesives or expandability of materials.

- Humidity: Avoid installation in excessively humid conditions to prevent the weakening of adhesives.

- Thermal Expansion: Aluminum expands and contracts with temperature changes. Allow for expansion joints or gaps to prevent buckling.

4. Structural Stability

- Load-Bearing Capacity: Ensure the structural frame or substrate can support the weight of the panels and any dynamic loads, such as wind pressure for external applications.

- Secure Fasteners: Use corrosion-resistant screws, bolts, and hangers to secure panels, particularly in outdoor environments.

5. Waterproofing and Sealing

- Joint Treatment: For external cladding, seal panel joints with weather-resistant silicone or polyurethane sealants to prevent water infiltration.

- Drainage Systems: Incorporate drainage channels where necessary to avoid water accumulation behind panels.

6. Safety Considerations

- High-Rise Installations: When working on high-rise buildings, use safety harnesses, scaffolding, or mobile platforms.

- Electrical Safety: Ensure that any electrical systems behind the panels are properly insulated and accessible for maintenance.

- Secure Storage: Store panels in a flat, dry area to prevent deformation or damage before installation.

FAQ About Aluminum Honeycomb Panel Installation

1. What is the best method to install aluminum honeycomb panels?

The best installation method depends on the application:

- For exterior facades, the dry hanging method is ideal due to its durability and ability to withstand environmental changes.

- For interior walls, adhesive bonding offers a cost-effective and visually seamless solution.

- For ceilings, the suspended framework method ensures stability and ease of maintenance.

Each method has unique benefits, so it’s important to choose one that aligns with the project’s structural and aesthetic requirements.

2. How do I ensure aluminum honeycomb panels are installed correctly?

Correct installation requires attention to several key factors:

- Surface preparation: Ensure the substrate or framework is clean, level, and structurally sound.

- Measurement accuracy: Use tools like laser levels to ensure panels are evenly aligned with proper spacing.

- Environmental conditions: Install in temperatures above 5°C and avoid high humidity to prevent adhesive failures.

- Thermal expansion: Allow for small gaps between panels to accommodate material expansion and contraction.

3. What are the most common mistakes to avoid during installation?

Some common mistakes to avoid include:

- Skipping surface preparation: Installing on uneven or dirty surfaces can lead to poor adhesion and structural instability.

- Neglecting thermal expansion gaps: Failing to account for aluminum’s expansion and contraction can cause buckling or warping.

- Improper sealing: For exterior installations, inadequate sealing at joints can result in water infiltration and damage.

- Using low-quality fasteners or adhesives: Ensure all materials meet the required specifications for long-term durability and performance.

By planning carefully and adhering to best practices, you can ensure a successful installation of aluminum honeycomb panels.