Aluminum microchannel tubes and aluminum multi-channel tubes are a type of heat exchanger that uses a network of small channels to transfer heat from one fluid to another. These tubes are made from high-purity aluminum alloys, which are known for their high strength, corrosion resistance, and heat transfer properties. In this article, we will explore the types, materials, applications, and advantages of aluminum microchannel tubes and aluminum multi-channel tubes.

What are the Types of Aluminum Micro Channel Tubes and Aluminum Multi-Channel Tubes?

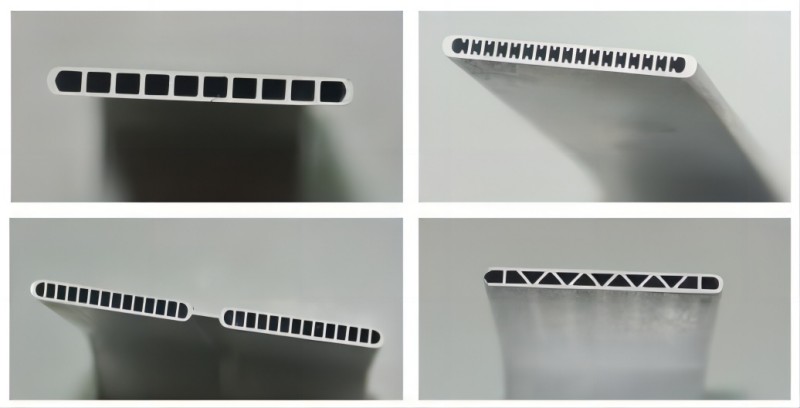

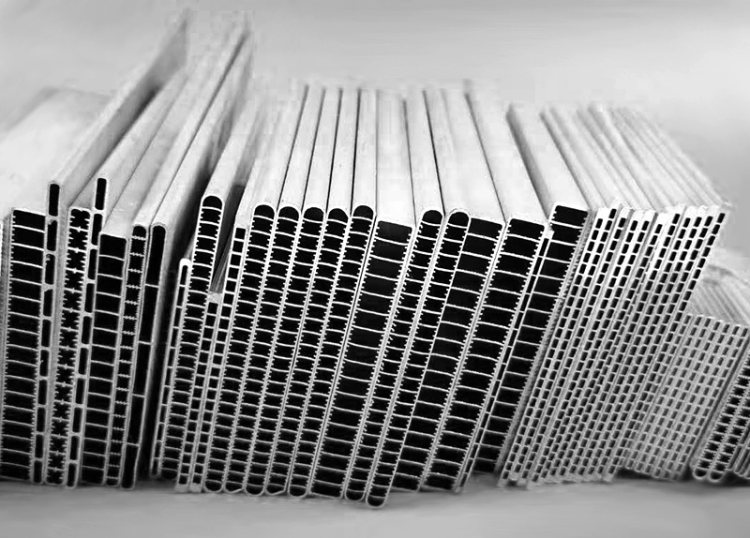

There are two main types of aluminum microchannel tubes: flat and rectangular. Flat aluminum microchannel tubes are typically used in heat exchangers, while rectangular aluminum microchannel tubes are typically used in cooling systems.

- Flat aluminum microchannel tubes are made by extruding a flat aluminum billet through a die with a series of small channels. The channels are typically 0.1 to 0.5 millimeters in diameter, and they are spaced 0.1 to 0.5 millimeters apart.

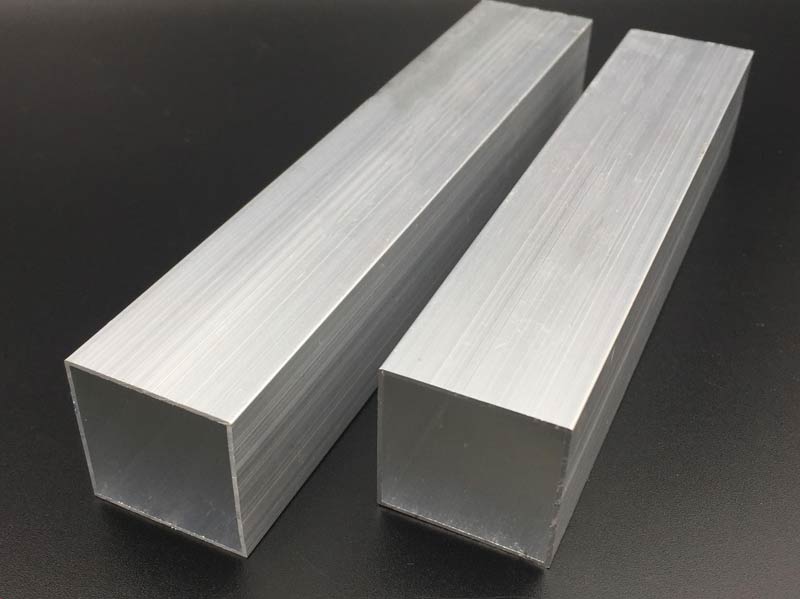

- Rectangular aluminum microchannel tubes are made by extruding a rectangular aluminum billet through a die with a series of small channels. The channels are typically 0.1 to 0.5 millimeters in diameter, and they are spaced 0.1 to 0.5 millimeters apart.

Aluminum multi-channel tubes are also available in a variety of shapes, including round, square, and hexagonal. These tubes are typically made by extrusion, but they can also be made by welding or brazing.

What are the Materials Used in Aluminum Micro Channel Tubes and Aluminum Multi-Channel Tubes?

Aluminum microchannel tubes and aluminum multi-channel tubes are typically made from high-purity aluminum alloys. These alloys are known for their high strength, corrosion resistance, and heat transfer properties.

The most common aluminum alloy used for microchannel tubes is 6063. This alloy is known for its high strength and corrosion resistance. It is also relatively easy to machine and fabricate.

Other aluminum alloys that are sometimes used for microchannel tubes include 6061, 6005, and 5052. These alloys offer a variety of properties, such as increased strength, improved corrosion resistance, or better weldability.

What are the Applications of Aluminum Micro Channel Tubes and Aluminum Multi-Channel Tubes?

Aluminum microchannel tubes and aluminum multi-channel tubes are used in a wide variety of applications, including:

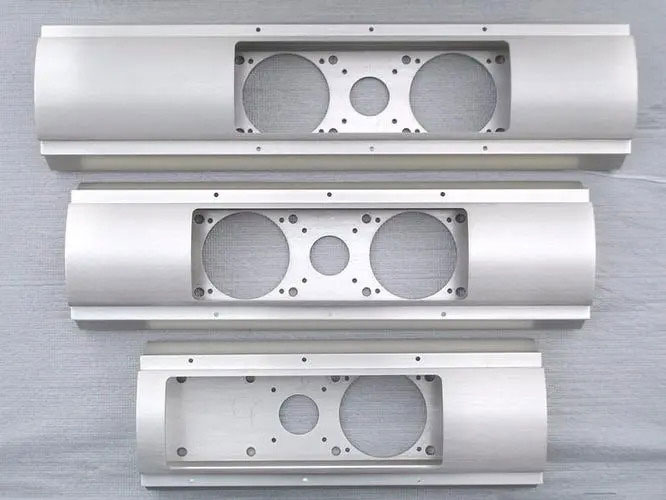

- Heat exchangers: Microchannel tubes are used in heat exchangers to transfer heat from one fluid to another. Heat exchangers are used in a variety of applications, including air conditioning systems, refrigeration systems, and industrial process heat exchangers.

- Cooling systems: Microchannel tubes are also used in cooling systems to transfer heat from a hot surface to a cooler fluid. Cooling systems are used in a variety of applications, including computers, electronics, and medical devices.

- HVAC systems: Microchannel tubes are used in HVAC systems to transfer heat from the air inside a building to the outside air. HVAC systems are used to heat and cool buildings and they are a major part of the infrastructure of modern society.

- Electronics: Microchannel tubes are used in electronics to transfer heat from electronic components to a cooler fluid. This helps to keep the electronic components cool, which prevents them from overheating and malfunctioning.

- Medical devices: Microchannel tubes are used in medical devices to transfer heat from the body to a cooler fluid. This helps to cool the body, which is important for medical procedures such as surgery.

What are the Benefits of Using Aluminum Micro Channel Tubes and Multi-Channel Tubes?

There are several benefits to using aluminum microchannel tubes and aluminum multi-channel tubes, including:

- High heat transfer efficiency: Microchannel tubes have a very high heat transfer efficiency, which means they can quickly transfer heat. This is because the small channels in the tubes provide a large surface area for heat transfer.

- Light weight: Aluminum microchannel tubes are very lightweight, which makes them easy to transport and install. This is especially important for portable heat exchangers and cooling systems.

- Corrosion resistance: Aluminum microchannel tubes are resistant to corrosion, which means that they can last for many years in harsh environments. This is important for applications where the heat exchanger or cooling system will be exposed to corrosive fluids or chemicals.

Conclusion

Aluminum microchannel tubes and aluminum multi-channel tubes are a versatile and efficient heat transfer solution. These tubes are available in a variety of shapes, sizes, and materials, making them suitable for a wide range of applications. The benefits of using aluminum microchannel tubes and aluminum multi-channel tubes include high heat transfer efficiency, light weight, and corrosion resistance.