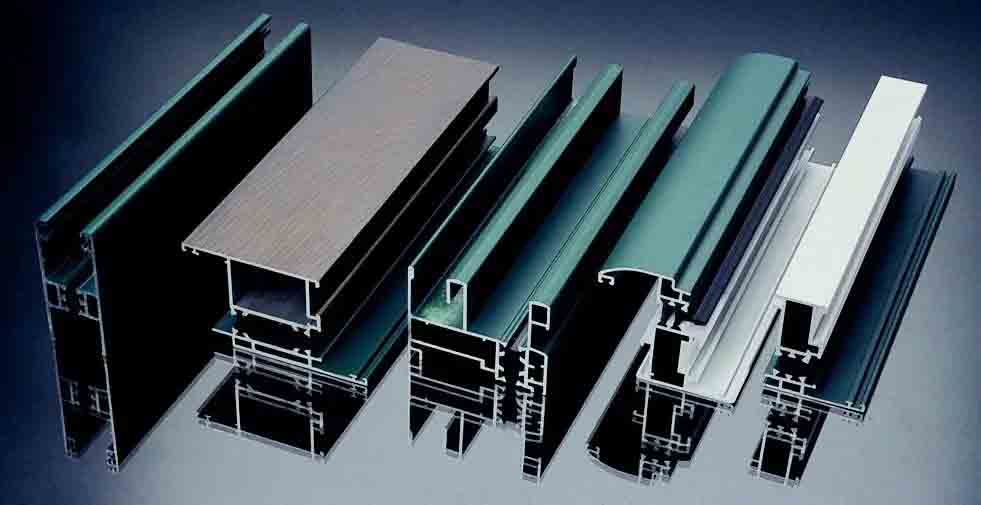

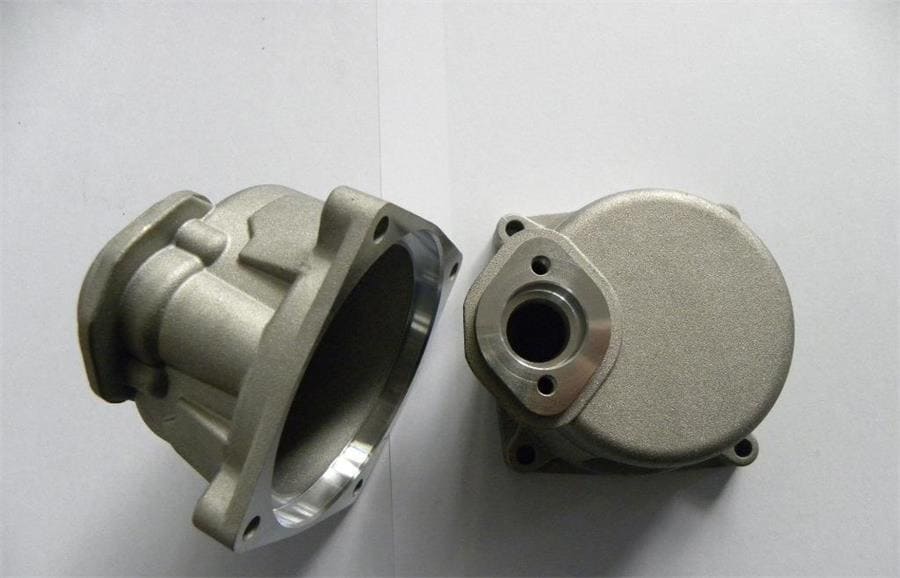

Aluminum Motor Housing Extrusion has become an increasingly popular material in motor design and manufacturing due to its many advantages. This material is lightweight, has high strength, is resistant to corrosion, and has excellent thermal management properties. As a result, it is increasingly being used in a wide range of applications across various industries. In this article, we will explore some of the real-world applications of Aluminum Motor Housing Extrusion and how it has been used to improve motor performance, efficiency, and reliability.

Aluminum Motor Housing Extrusion in Automotive Industry

One of the most significant applications of Aluminum Motor Housing Extrusion is in the automotive industry. With the rise of electric vehicles (EVs) and hybrid vehicles, motor designers are looking for ways to reduce weight and improve thermal management. Aluminum Motor Housing Extrusion provides a lightweight and durable solution for this challenge. For example, Tesla’s Model S uses a rear motor with an Aluminum Motor Housing Extrusion, which reduces weight and improves performance and efficiency. The use of Aluminum Motor Housing Extrusion allows for a reduction in weight, which in turn, improves the acceleration and overall performance of the vehicle. In addition, the material’s thermal conductivity allows for better heat dissipation, improving the lifespan and reliability of the motor.

Another example of Aluminum Motor Housing Extrusion in the automotive industry is the high-performance sports car, the Audi R8. The car’s V10 engine uses Aluminum Motor Housing Extrusion to reduce weight and improve thermal management, resulting in a faster and more efficient vehicle. The use of Aluminum Motor Housing Extrusion has allowed for a reduction in weight, which has improved the vehicle’s handling and responsiveness. Furthermore, the material’s ability to conduct heat away from the motor also results in improved reliability. By using Aluminum Motor Housing Extrusion, motor designers in the automotive industry have been able to improve motor performance, efficiency, and reliability.

Aluminum Motor Housing Extrusion in Aerospace Industry

The aerospace industry also uses Aluminum Motor Housing Extrusion in various applications, including aircraft engines, satellite propulsion systems, and space launch vehicles. The high strength-to-weight ratio of Aluminum Motor Housing Extrusion makes it an ideal material for aerospace applications. For instance, the Pratt & Whitney F135 engine, which powers the F-35 Lightning II fighter jet, uses an Aluminum Motor Housing Extrusion to reduce weight and improve engine performance. The use of Aluminum Motor Housing Extrusion has allowed for a reduction in weight, which has improved the engine’s performance and fuel efficiency. The material’s corrosion resistance also makes it ideal for use in harsh environments. Aluminum Motor Housing Extrusion has become an essential material in the aerospace industry, where weight reduction and reliability are critical.

Industrial Machinery and Consumer Electronics

The use of Aluminum Motor Housing Extrusion is not limited to the automotive and aerospace industries. It is also used in a variety of industrial machinery and consumer electronics applications. For instance, power tools, home appliances, and computer peripherals all use motors that could benefit from Aluminum Motor Housing Extrusion. The material’s thermal management properties allow for better heat dissipation, reducing the temperature of the motor and improving its lifespan.

A good example of this is the electric drill. Aluminum Motor Housing Extrusion is used to reduce the weight of the drill, making it easier for users to handle and improving overall performance and efficiency. In addition, the material’s thermal management properties help to reduce the temperature of the drill’s motor, improving its lifespan. The use of Aluminum Motor Housing Extrusion in power tools has become increasingly popular due to its ability to improve performance and reduce weight, making it easier for workers to use for longer periods of time.

In conclusion, Aluminum Motor Housing Extrusion is a versatile and effective material that has numerous benefits for motor design and manufacturing. It is being used in a wide range of applications across various industries, from the automotive and aerospace industries to industrial machinery and consumer electronics. By using Aluminum Motor Housing Extrusion, motor designers have been able to improve motor performance, efficiency, and reliability. Its lightweight and durable properties, combined with its excellent thermal management capabilities and resistance to corrosion, make it an ideal material for a wide range of motor applications. As technology continues to evolve, we can expect to see more innovative uses of Aluminum Motor Housing Extrusion in the future.