Aluminum panels have become a preferred choice in modern construction for both interior and exterior walls due to their durability, aesthetic appeal, and versatility. However, selecting the right aluminum panel requires an understanding of the specific needs of the application. This article provides a comprehensive guide to comparing performance indicators, key selection points, and recommendations for typical scenarios to help you make informed decisions.

Comparison of Interior and Exterior Aluminum Panels

While both interior and exterior aluminum panels share the fundamental material, their core performance requirements diverge considerably. Exterior panels face harsh environmental conditions, demanding superior durability and structural integrity compared to interior panels, which primarily focus on aesthetics and indoor environmental quality. The following table and detailed explanations highlight the key differences in their core performance indicators:

| Parameter | Interior Wall Panels | Exterior Wall Panels |

| Recommended Thickness | 1.5-3.0mm (with core layer) | 2.5-4.0mm (solid aluminum) |

| Aluminum Layer Thickness | ≥0.2mm (composite panels) | ≥0.5mm (single-layer panels) |

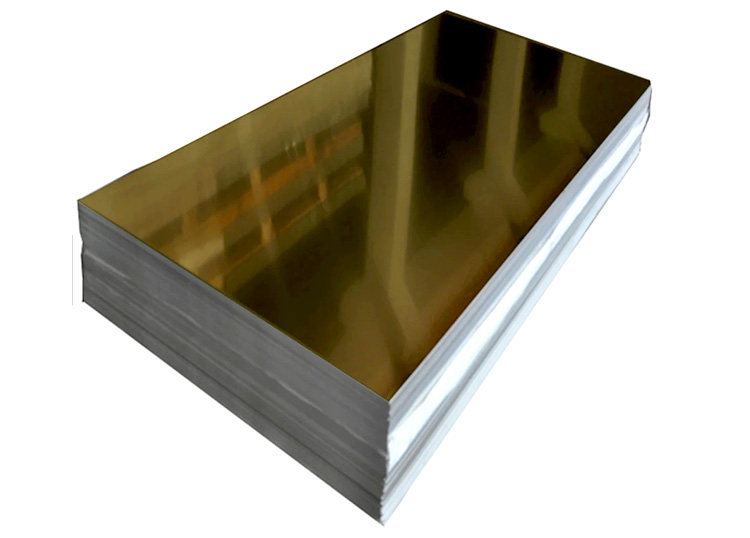

| Surface Treatment | Polyester Powder/Standard PVDF Coating | Three-coat PVDF System (Primer+Color+Clear) |

| Fire Rating | B1 (composite core) | A2 (non-combustible) |

| Weather Resistance | Artificial Aging Resistance ≥1000 hours | Artificial Aging Resistance ≥4000 hours |

| Wind Load Resistance | ≥1.5kPa | ≥3.0kPa (typhoon-resistant) |

| Thermal Expansion Coefficient | 23×10⁻⁶/℃ (0.5cm expansion gap required) | Same, but enhanced sealing required |

| Environmental Standards | E1 (formaldehyde ≤0.5mg/m³) | Zero VOC, 100% recyclable |

When choosing aluminum panels for interior and exterior use, it is crucial to consider several performance metrics. These include thickness, surface treatment, fire resistance, environmental standards, and more.

How to Choose Aluminum Panels for Interior and Exterior Walls?

The use environment of aluminum plates is different, and the requirements for characteristics are also different. Different aspects should be considered when choosing aluminum plates for indoor and outdoor use.

Key Considerations for Choosing Interior Aluminum Panels

Selecting the right aluminum panels for interior applications involves balancing aesthetic appeal with functional requirements and ensuring a healthy and safe indoor environment. Here are the key factors to consider:

Material Selection: The choice of aluminum alloy for interior panels is often driven by cost-effectiveness and formability. Common alloys include the 1000 series (pure aluminum) and some 3000 series alloys, which offer good workability and corrosion resistance for indoor environments. The thickness will depend on the specific application and desired aesthetic, with thinner gauges generally sufficient for wall cladding and decorative elements.

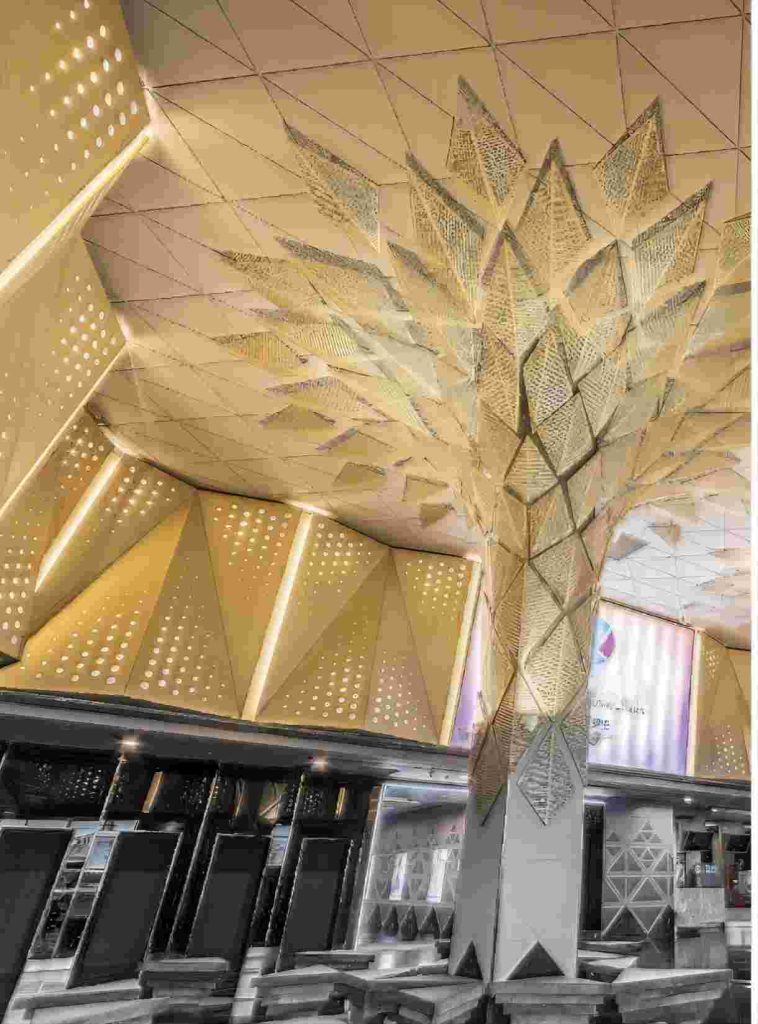

Surface Treatment: Interior aluminum panels offer a vast array of surface treatments to match diverse design aesthetics. Powder coating provides a durable and colorful finish with good scratch resistance. Anodizing creates a metallic sheen and enhances corrosion resistance. PE coatings offer a cost-effective solution for decorative purposes. Additionally, various textured finishes, including wood grain and stone grain effects, can be achieved through specialized coatings or laminates. The selection should consider the desired visual impact, durability requirements in high-traffic areas, and ease of cleaning.

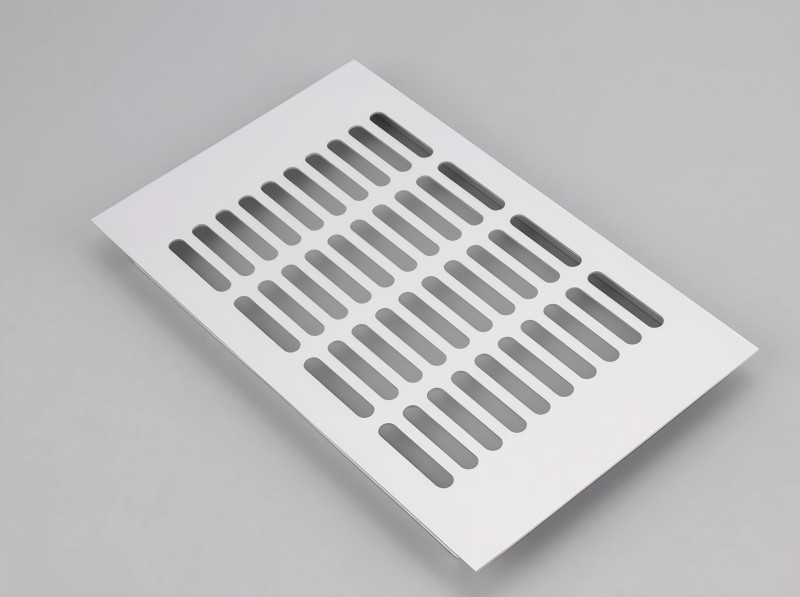

Environmental and Safety Aspects: Ensuring good indoor air quality is crucial. Opt for panels and adhesives with low VOC emissions to minimize potential health risks. Fire safety is also a consideration, especially in public spaces. Check the fire rating of the panels to comply with building codes and ensure adequate safety in case of a fire. Consider the recyclability of the aluminum material as part of a sustainable design approach.

Installation Adaptability: The ease of installation and compatibility with the existing wall structure are important practical considerations. Choose panel sizes and fixing systems that are efficient and cost-effective to install. Consider factors like cutting, shaping, and integration with other interior elements such as doors, windows, and lighting fixtures.

In summary, selecting interior aluminum panels involves a careful consideration of the desired aesthetic, the functional requirements of the space, the impact on indoor environmental quality and safety, and the practicality of installation. By balancing these factors, you can choose panels that enhance the interior design while ensuring a comfortable and healthy environment.

Key Considerations for Choosing Exterior Aluminum Panels

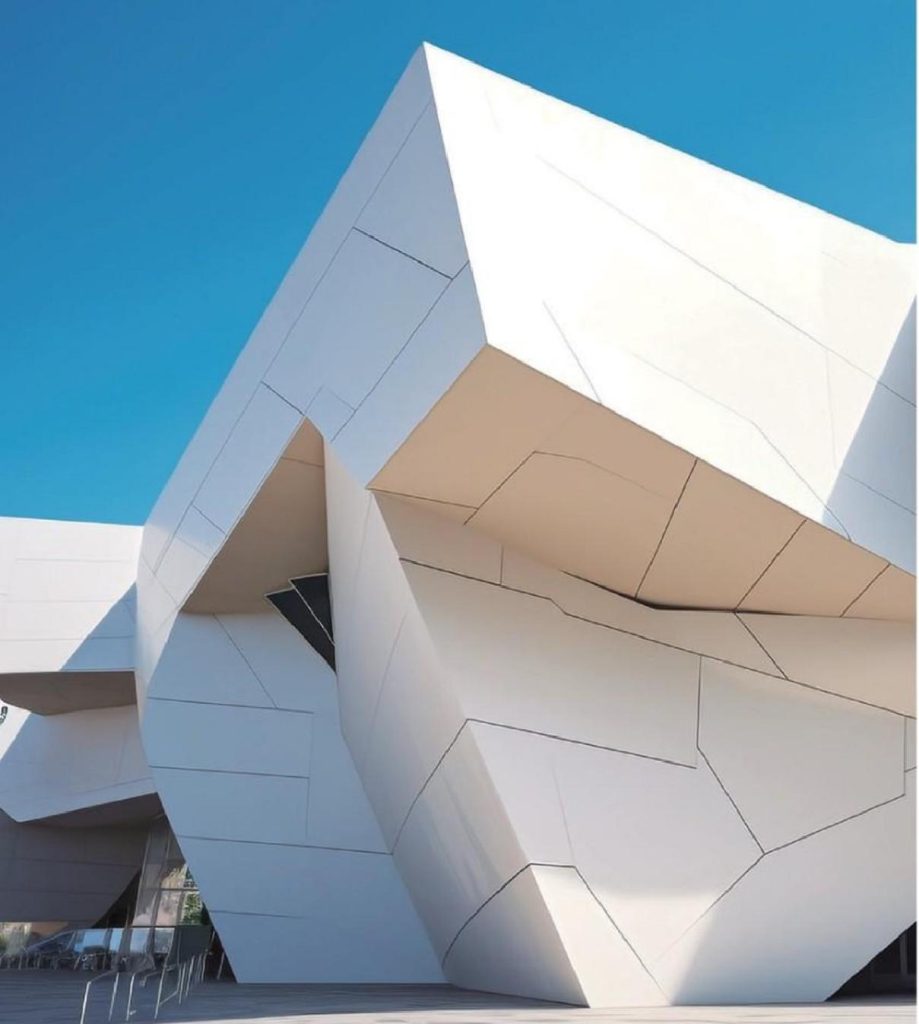

Selecting aluminum panels for exterior walls demands a focus on durability, structural integrity, and long-term performance under harsh environmental conditions. Here are the critical factors to consider:

Material Strength: Exterior aluminum panels must possess sufficient strength to withstand wind loads, impact, and other external stresses. Choosing the right aluminum alloy (e.g., 3003, 5052) with adequate thickness (typically 2.0mm to 4.0mm or more) is crucial. The temper of the aluminum alloy also affects its strength and should be specified based on the project requirements.

Weather Resistance: As discussed earlier, superior weather resistance is paramount for exterior panels. Opt for high-performance PVDF coatings that offer excellent resistance to UV radiation, acid rain, salt spray, temperature fluctuations, and humidity. The number of PVDF coating layers (typically two or three) and the quality of the application process also significantly impact long-term performance.

Structural Safety: The structural design and installation of exterior aluminum panels are critical for ensuring safety and preventing failures. This includes the design of the supporting framework, the fixing methods (e.g., rivets, screws, adhesives), and the provision of adequate expansion and contraction joints to accommodate thermal movement. Engineering calculations based on wind loads and seismic activity are essential to ensure the structural integrity of the cladding system.

Special Environmental Considerations: Depending on the specific location of the building, additional environmental factors may need to be considered. For coastal areas, enhanced resistance to salt spray corrosion is crucial. In industrial areas, resistance to chemical pollutants may be necessary. For regions with extreme temperature variations, the thermal expansion properties of the panels and the design of the attachment system need careful attention.

In conclusion, the selection of exterior aluminum panels requires a strong emphasis on material strength, long-term weather resistance, robust structural design, and consideration of any specific environmental challenges. By carefully evaluating these factors and adhering to relevant building codes and engineering best practices, you can ensure a safe, durable, and aesthetically pleasing building facade.

Typical Scenario Recommendation Schemes

The following table provides recommended aluminum panel specifications for various typical application scenarios, considering the specific performance requirements of each:

| Scenario | Recommended Thickness (mm) | Aluminum Alloy Type | Coating Type | Specific Requirements |

| Residential Bathroom (Interior) | 0.8 – 1.2 | 3003 | Powder Coating | Moisture resistance, easy to clean, aesthetically pleasing. |

| Commercial Curtain Wall (Exterior) | 2.5 – 3.0 | 3003 or 5052 | PVDF | High wind pressure resistance, excellent weatherability, long-term color retention. |

| Hospital Operating Room (Interior) | 1.0 – 1.5 | 3003 | Anti-bacterial Powder Coating | Easy to clean and disinfect, good durability, hygienic. |

| Coastal High-Rise Building (Exterior) | 3.0 – 4.0 | 5052 | PVDF (3-Layer) | Superior corrosion resistance (salt spray), high wind pressure resistance, excellent weatherability. |

These are general recommendations, and specific project requirements may necessitate adjustments. Consulting with aluminum panel material suppliers and structural engineers is crucial for making informed decisions.