The aluminum perforated sheet has become an essential material in architecture, industry, and decorative fields due to its unique physical properties, superior manufacturing capabilities, and wide range of applications. This material is not only versatile in design but also excels in acoustic performance, making it ideal for sound insulation. This article explores the material characteristics, acoustic properties, functionalities, and applications of aluminum perforated sheets in soundproofing.

Material Characteristics of Aluminum Perforated Sheets

The widespread use of aluminum perforated sheets is largely attributed to their exceptional material properties, which ensure adaptability across various fields. These properties include:

1. Lightweight and High Strength

Compared to other metal materials such as steel, aluminum perforated sheets are significantly lighter, making them easier to transport and install. Despite their light weight, they possess considerable strength, capable of withstanding external forces without deformation. These traits make aluminum perforated sheets particularly suitable for large-scale architectural and decorative projects.

2. Corrosion Resistance

Aluminum has a natural resistance to corrosion, effectively withstanding oxidation and chemical corrosion in the atmosphere. Furthermore, surface treatments such as chromatin or fluorocarbon coating enhance its durability, allowing aluminum perforated sheets to maintain performance even in extreme environments.

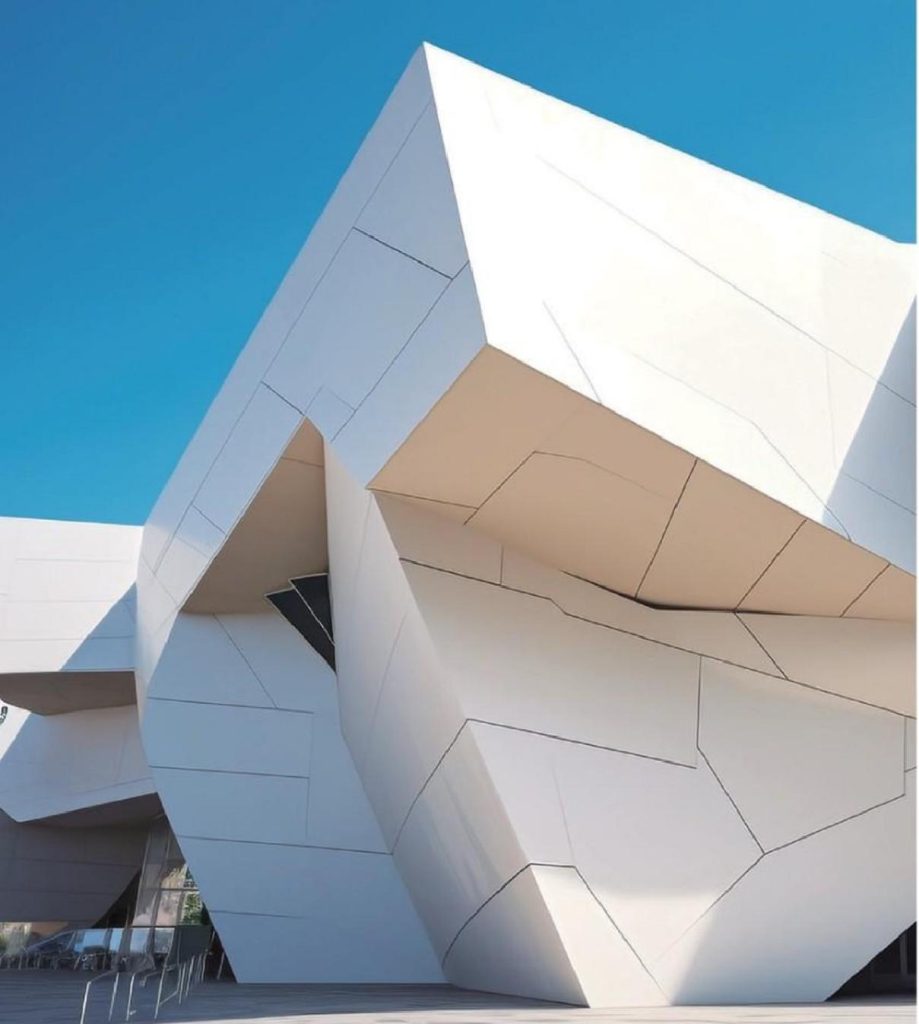

3. High Plasticity

The material’s malleability allows it to be fabricated into various shapes, including flat, curved, or spherical forms. This flexibility enables aluminum perforated sheets to meet complex architectural designs and diverse decorative styles.

4. Eco-Friendliness and Energy Efficiency

As a recyclable material, aluminum aligns with contemporary environmental standards. Additionally, aluminum perforated sheets exhibit excellent thermal insulation properties, which can significantly reduce energy consumption in buildings, especially in thermal and insulation applications.

Acoustic Properties of Aluminum Perforated Sheets

One of the most prominent features of aluminum perforated sheets is their superior acoustic performance. These sheets are designed not only to absorb sound waves effectively but also to reduce noise transmission, creating more comfortable environments.

1. Sound Absorption

Aluminum perforated sheets achieve sound absorption through precise perforation designs. These designs, often accompanied by an air layer at the back, create cavity resonance structures that significantly improve sound absorption coefficients within specific frequency ranges. The air layer enables aluminum perforated sheets to absorb both high-frequency and low-frequency noise, enhancing overall soundproofing effects.

2. Noise Reduction

Aluminum perforated sheets offer excellent soundproofing in environments requiring high acoustic quality, such as recording studios, conference rooms, and cinemas. Their superior acoustic performance ensures a quieter, more focused space, enhancing sound quality and auditory experiences.

Soundproofing Principles and Applications

The soundproofing capabilities of aluminum perforated sheets are primarily based on cavity resonance structures and other acoustic principles.

Soundproofing Principles

- Helmholtz Resonators: The air layer behind the perforated sheet forms numerous small cavities. Each cavity, coupled with a corresponding hole, acts as a Helmholtz resonator. When external sound waves match the system’s natural frequency, the air columns within the holes resonate, dissipating sound wave energy and achieving sound absorption.

- High-Frequency Absorption: The perforation rate directly correlates with sound absorption efficiency. Higher perforation rates result in better absorption, particularly for high-frequency noise.

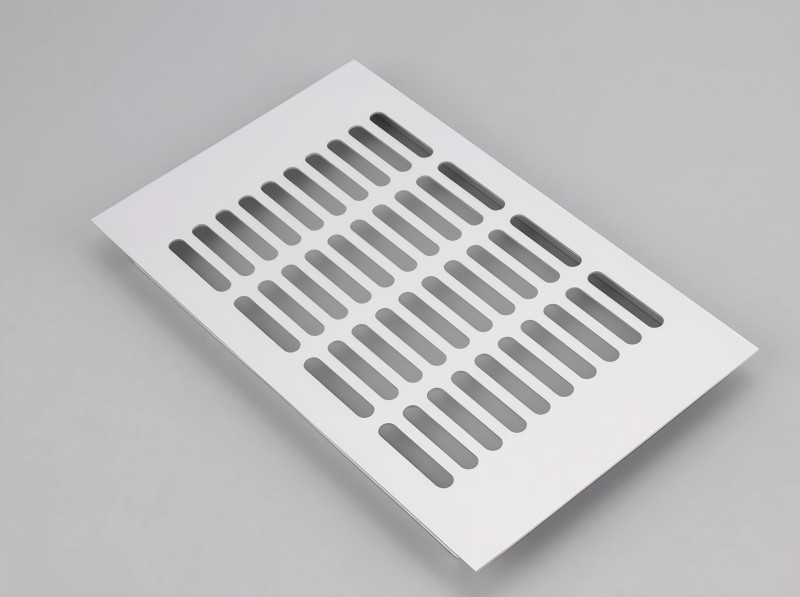

Types of Aluminum Perforated Sheets for Soundproofing

- Standard Perforated Aluminum Sheets: Ideal for general noise reduction needs, providing basic soundproofing effects.

- Micro-Perforated Aluminum Sheets: Suitable for environments requiring high acoustic performance, such as recording studios, offering enhanced high-frequency noise absorption.

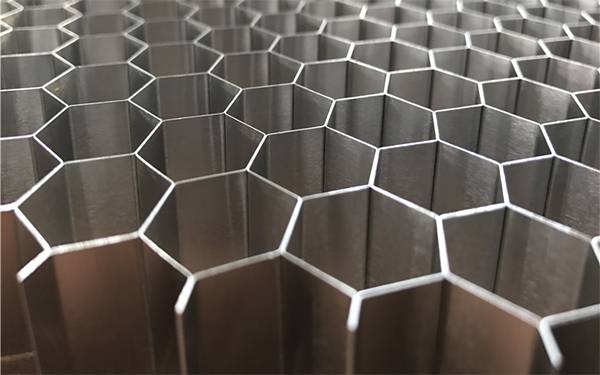

- Aluminum Honeycomb Perforated Sheets: These combine the features of honeycomb structures, delivering not only excellent soundproofing but also superior thermal insulation. They are widely used in architectural and industrial applications.

Factors Affecting Soundproofing

- Perforation Rate: The optimal perforation rate for soundproofing is typically 15%-25%.

- Hole Diameter: Larger holes improve low-frequency noise absorption, while smaller holes are more effective for high-frequency noise.

- Cavity Depth: Increasing cavity depth significantly enhances low-frequency sound absorption, especially for frequencies below 315 Hz.

Applications of Aluminum Perforated Sheets in Soundproofing

The excellent soundproofing properties of aluminum perforated sheets make them applicable across various fields:

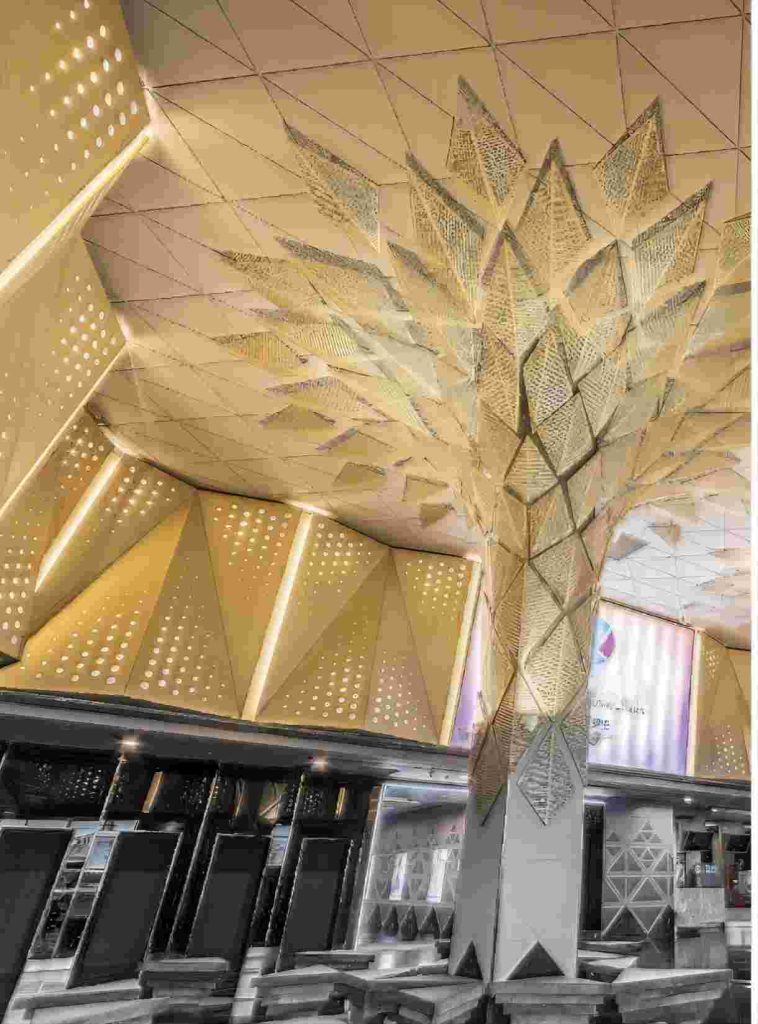

- Architectural Applications: Commonly used in hotels, cinemas, conference rooms, office buildings, and hospitals, aluminum perforated sheets improve acoustics and reduce noise disturbances in public buildings.

- Industrial Applications: In noisy industrial settings, such as mechanical workshops and textile factories, aluminum perforated sheets help create quieter work environments, enhancing employee comfort and productivity.

- Entertainment Venues: Aluminum perforated sheets are extensively used in opera houses, music halls, KTVs, and bars to create superior acoustic environments, enhancing auditory experiences and improving sound system effects.

Decorative and Functional Advantages

Apart from their acoustic benefits, aluminum perforated sheets offer significant decorative and functional advantages.

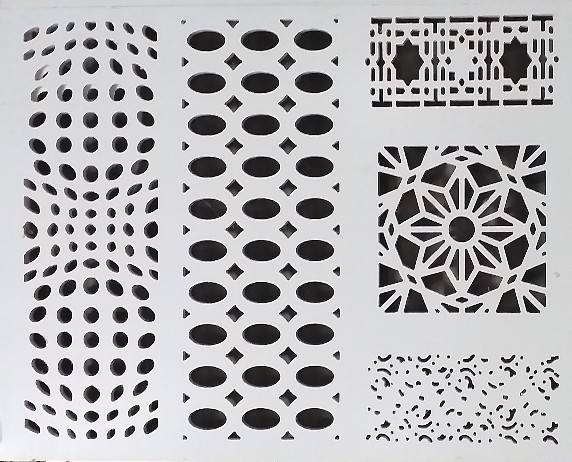

Decorative Benefits

Aluminum perforated sheets can be customized with various hole shapes (e.g., circular, square, or oblong) and patterns to create unique façade effects. These designs not only enhance the aesthetic appeal of buildings but also blend harmoniously with surrounding environments. Surface treatments, such as spraying, baking, and wood-grain transfer printing, provide diverse colors and textures to meet different decorative needs.

Functional Benefits

- Ventilation and Heat Dissipation: The perforations facilitate airflow, making aluminum perforated sheets ideal for applications in coolers, fans, and air conditioning systems.

- Sunshade and Lighting: Aluminum perforated sheets effectively filter sunlight, reducing indoor heat radiation while maintaining adequate natural lighting, particularly in building façade shading systems.

- Safety and Protection: With carefully designed perforation patterns, aluminum perforated sheets can be used as burglar-proof windows, protective barriers, and safety equipment, ensuring security without obstructing visibility.

Installation and Maintenance

The ease of installation and maintenance is another reason for the widespread adoption of aluminum perforated sheets.

- Simple Installation: The straightforward manufacturing process and installation techniques reduce labor costs and construction time.

- Easy Maintenance: The smooth surface and non-stick coating of aluminum perforated sheets make cleaning and upkeep hassle-free, extending their lifespan.

In summary, aluminum perforated sheets have established themselves as indispensable materials across multiple industries due to their unique physical properties, exceptional acoustic performance, and versatility. Their soundproofing capabilities, combined with decorative and functional advantages, make them ideal for a wide range of applications in architecture, industry, and entertainment. With ongoing technological advancements, aluminum perforated sheets are expected to gain even broader applications, contributing to the creation of more comfortable, eco-friendly living and working environments.