Aluminum perforated sheets are an essential component in various industries due to their versatility and functionality. These sheets, characterized by their patterned holes, offer a blend of aesthetic appeal and practical benefits. Whether in architecture, industrial applications, or design, aluminum perforated sheets provide solutions that are both innovative and efficient. This article will explore the different types of aluminum perforated sheets and their numerous applications.

Why Using Aluminum Perforated Sheets?

Aluminum perforated sheets are popular for several reasons:

- Durability and Strength: Despite being lightweight, aluminum provides robust structural integrity, making these sheets ideal for demanding applications.

- Corrosion Resistance: Aluminum naturally resists rust and corrosion, which is crucial for long-term durability, especially in harsh environments.

- Lightweight Nature: The lightweight nature of aluminum reduces the load on structures and makes handling and installation easier.

- Versatility in Design: The variety of hole shapes and patterns allows for creative design solutions, meeting both functional and aesthetic requirements.

- Cost-effectiveness: Aluminum perforated sheets are relatively inexpensive compared to other materials, providing a cost-effective solution for many projects.

- Environmental Benefits: Aluminum is highly recyclable, contributing to environmental sustainability and reducing the carbon footprint.

Types of Aluminum Perforated Sheets

Aluminum perforated sheets come in various types and classifications based on different criteria. Here are the details:

Based on Hole Shape

| Hole Shape | Characteristics | Uses |

| Round Hole Perforated Sheets | Most common type of perforation. Available in various diameters. Provides a balanced open area and structural strength. | Aesthetic applications, Ventilation and airflow, Filtration, Screens and grilles. |

| Square Hole Perforated Sheets | Distinct geometric shape. Uniform open area. Can offer more rigidity compared to round holes. | Architectural applications, Screens and partitions, Decorative panels. |

| Slotted Hole Perforated Sheets | Elongated holes, which can be aligned vertically, horizontally, or diagonally. Offers directional strength. | Drainage applications, Airflow increase, Filtering and sieving, Architectural features. |

| Hexagonal Hole Perforated Sheets | Honeycomb pattern. High open area with good strength-to-weight ratio. | Architectural cladding, Acoustic panels, Structural components. |

| Diamond Hole Perforated Sheets | Diamond-shaped holes. Provides a unique visual appearance. | Decorative applications, Grilles and screens. |

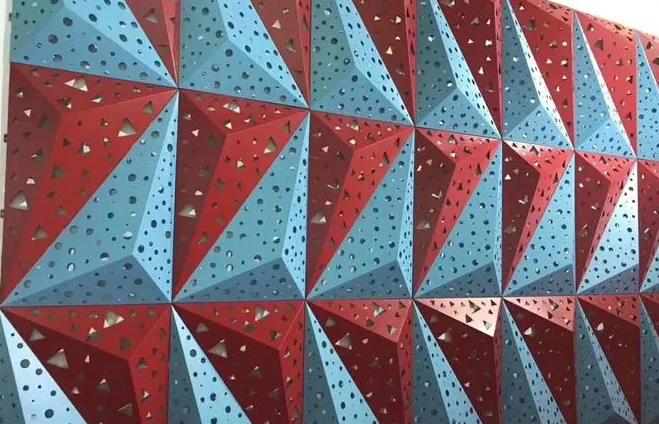

| Triangular Hole Perforated Sheets | Triangular holes. Uncommon, providing a unique aesthetic. | Special design requirements, Unique visual effects. |

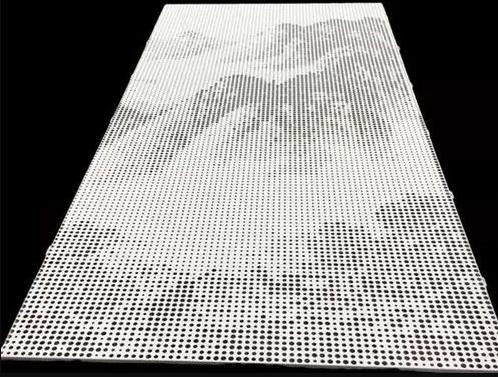

| Custom Shapes Perforated Sheets | Holes can be tailored to specific shapes and sizes. Can be designed to meet unique requirements. | Customized architectural designs, Branding elements, Special functional applications. |

Based on Pattern

| Pattern Type | Characteristics | Uses |

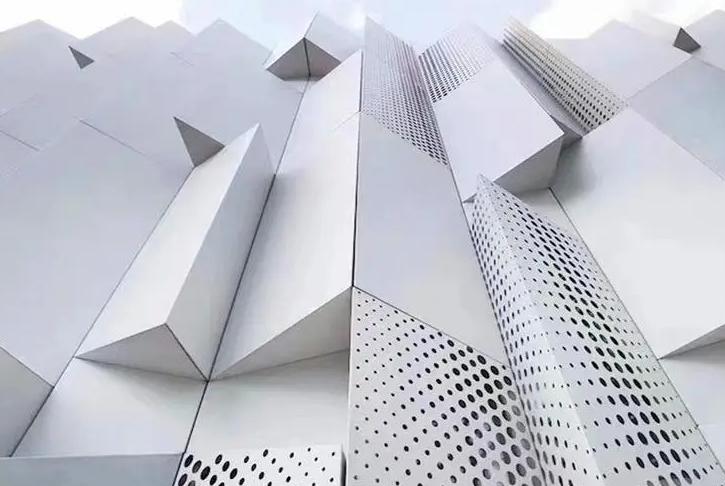

| Staggered Perforated Sheets (60° or 45°) | Holes are offset in a staggered pattern. Offers increased structural strength. Provides an aesthetic appeal. | Industrial applications, Architectural facades, Filtration systems, Noise control panels |

| Straight Perforated Sheets (90°) Pattern | Holes are aligned in straight rows and columns. Uniform and grid-like appearance. Even distribution of load. | Decorative panels, Signage, Ventilation grilles, Shelving and storage solutions |

| Diagonal Pattern Perforated Sheets | Holes are aligned diagonally. Offers a distinctive look. Can provide directional strength. | Aesthetic applications, Architectural features, Design-specific applications |

| Custom Patterns Perforated Sheets | Holes are arranged in tailored designs. Can be customized to meet unique visual or functional needs. | Customized architectural designs, Brand-specific elements, Unique functional requirements |

Based on Material Thickness

| Material Thickness | Characteristics | Uses |

| Thin Gauge Perforated Sheets (0.5mm to 1.5mm) | Lightweight and easy to handle. Less structural strength. Suitable for delicate applications. | Interior design, Cladding, Lightweight partitions, Decorative panels |

| Medium Gauge Perforated Sheets (1.5mm to 3mm) | Balance between strength and flexibility. Moderate weight and durability. | Signage, Facades, Moderate load-bearing structures, Screens and grilles |

| Thick Gauge Perforated Sheets (3mm and above) | Heavy-duty and robust. High structural strength. Suitable for demanding applications. | Industrial flooring, Heavy-duty screens, Load-bearing structures, Structural components |

Based on Finish

| Finish Type | Characteristics | Uses |

| Milled Perforated Sheets | Basic, untreated aluminum. Natural, matte appearance. Economical option. | Applications where appearance is not critical, Functional uses, Industrial environments |

| Anodized Perforated Sheets | Electrochemically treated. Enhanced corrosion resistance. Available in various colors. | Exterior architectural elements, High-traffic areas, Decorative applications |

| Powder Coated Perforated Sheets | Coated with dry powder and cured under heat. Durable and uniform finish. Wide range of colors and textures. | Outdoor applications, Signage Architectural elements, Protective applications |

| Polished Perforated Sheets | Mechanically polished to a reflective, shiny surface. Aesthetic and clean appearance. | Decorative panels, High-visibility areas, Reflective surfaces |

| Brushed Perforated Sheets | Surface brushed to create a uniform, satin-like texture. Reduces glare. | Architectural applications, Decorative panels, Interior design |

| Painted Perforated Sheets | Coated with liquid paint. Can match specific color requirements. Provides protective layer. | Custom color requirements, Decorative elements, Both interior and exterior applications |

| Embossed Perforated Sheets | Raised or recessed pattern on the surface. Textured appearance. | Decorative applications, Enhanced grip surfaces, Unique aesthetic features |

Common Applications From Types

Aluminum perforated sheets find their way into various applications based on their types:

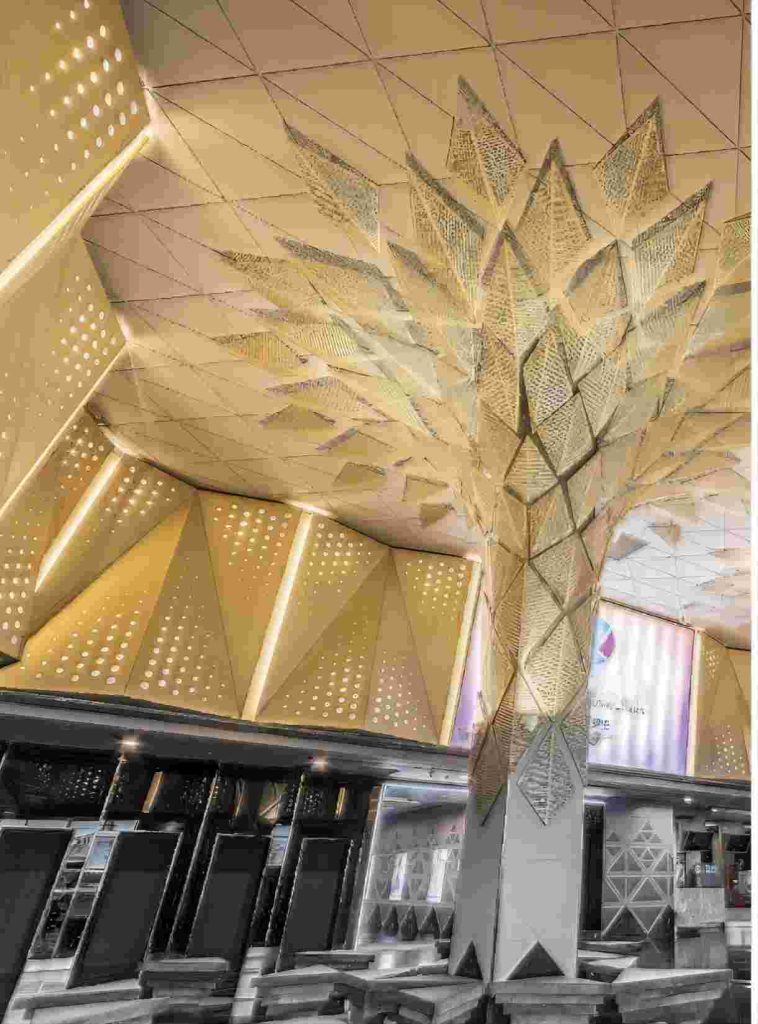

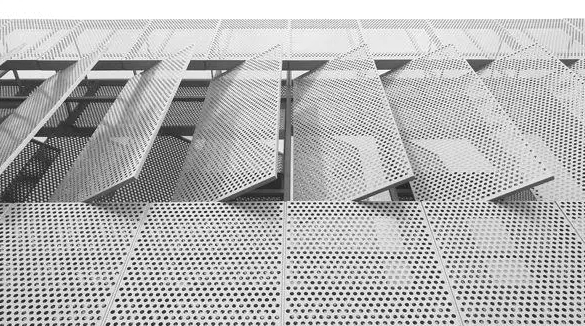

Architectural Applications:

Facades and Cladding: Hexagonal and round hole sheets are often used for building exteriors.

Interior Design: Square hole and staggered pattern sheets are popular for ceilings, partitions, and decorative elements.

Industrial Applications:

Filtration and Sieving: Round hole and slotted hole sheets are essential in filtering processes.

Ventilation and Soundproofing: Thick gauge and staggered pattern sheets are used to ensure proper air flow and noise reduction.

Automotive Applications:

Grilles and Muffler Components: Durable, thick gauge sheets with various hole patterns are utilized for automotive parts.

Furniture and Design:

Modern Furniture: Thin gauge and powder-coated sheets are used in contemporary furniture designs for their lightweight and aesthetic properties.

Food and Beverage Industry:

Screening and Sieving: Aluminum sheets with round holes are used in food processing and packaging.

Aluminum perforated sheets are a versatile and indispensable material in numerous industries. Their wide range of types, based on hole shape, pattern, material thickness, and finish, allows them to meet diverse functional and aesthetic needs. From architectural facades to industrial filtration systems, these sheets offer durability, lightweight properties, and cost-effectiveness, making them a preferred choice for many applications. CHAL as a professional aluminum products supplier, also can provide you aluminum perforated sheets. If you need it or want to customize the sheet, please feel free to contact us.