Aluminum tubes and aluminum pipes are both names for aluminum hollow cylinders. Often, these words are used interchangeably. Both “aluminum tube” and “aluminum pipe” are long hollow cylinders. But engineers, are different, they are not the same thing.

Definition of Hollow Cylinder

The cylindrical shape in the hollow cylinder is composed of a curved surface and two circular bottom surfaces, and the cylindrical shape has only a curved surface and no bottom surface. A cylinder is a geometric body formed by taking the straight line of one side of a rectangle as the axis of rotation, and the other three sides rotate around the axis of rotation. It has 2 parallel circular bottoms of the same size and 1 curved side.

Therefore, both aluminum tubes and aluminum pipes are standard hollow cylinders. It seems that there is no difference between them. But this is a misconception, and their differences are attributed to differences in how they are measured, and how they are defined differently.

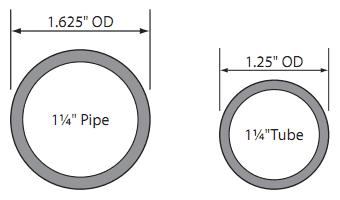

In short: Aluminum tubes are measured by the outer diameter, and the inner diameter measures aluminum pipes. There is often confusion as to which size mold the customer needs – pipe size or tubing size.

An aluminum pipe is defined by its internal diameter (ID) or bore because it’s used for transporting fluid or other media. The ID matters because that determines the capacity of the pipe, which is usually the property of most significant interest to the buyer.

An aluminum round tube is defined by its outside diameter (OD). That’s because the tube is for structural uses. The bore isn’t particularly relevant to the end users but the OD probably matters a great deal. For example, the actual outside diameter of 1¼″ pipe is 1.625″ – while 1¼″ tube has a true 1.25″ outside diameter.

And the tube doesn’t have to be round! You may be wondering at this point, but “tube” really just means a closed internal passage. For example, you can buy square and rectangular as well as aluminum round tubing. They are widely known as aluminum tubes, but their shape is not round.

Manufacture of Aluminum Pipe and Aluminum Tube

So why not simply define both the ID and OD? The response comes down to the manufacturing processes and also where you want the natural process variation to be. You can have a consistent bore or a regular OD, however, you can’t have both. A minimum of, not too high precision.

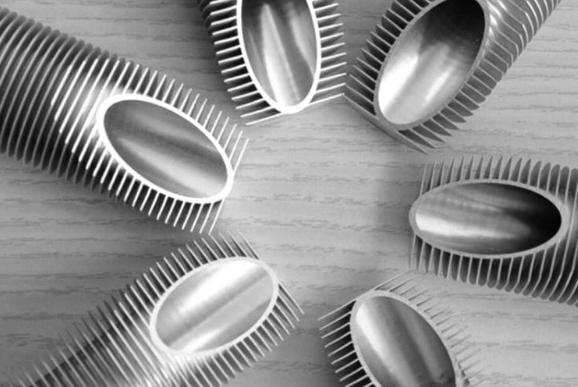

The majority of smaller-sized bore metal pipeline and also tube is squeezed out. That’s the procedure where a billet of product is squeezed with a die to generate a long length with a uniform cross-section. It works best with pliable materials, which is why a lot of aluminum is squeezed out.

Squeezing out a pipeline or tube entails compelling the metal around a mandrel that creates the internal path. In practice it isn’t easy to maintain this interior birthed concentric with the OD, so what takes place is that the wall surface density varies. The supplier manages either birthed or OD, but not both.

Some tubes will be drawn after extrusion, (or in some cases, as opposed to,) both to slim it down and to boost dimensional consistency. Drawing is similar to extrusion because the product passes through a die and over a mandrel, yet the difference is that it’s pulled instead of pushed.

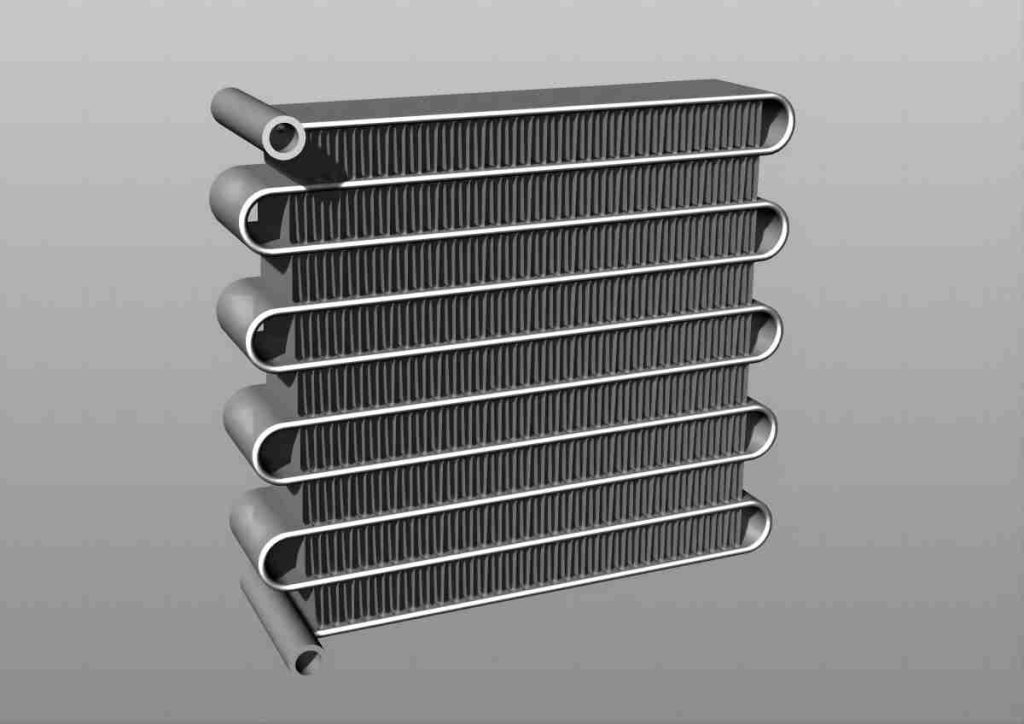

Applications for Extruded Round Pipe

Among the largest usages remains in warmth exchangers. This is because lightweight aluminum has outstanding thermal conductivity, as well as welds conveniently. Being light, it’s additionally sought after for solar home heating water supply where it won’t put way too much weight on a roofing system.

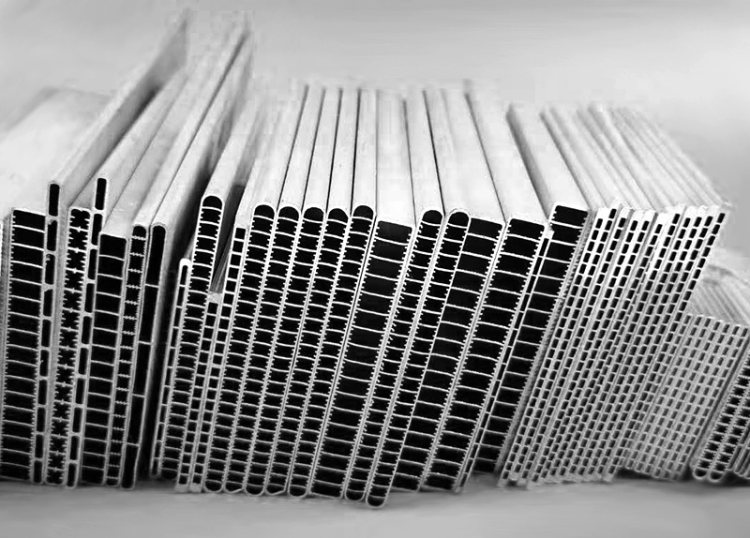

Applications for Extruded Tube

Extruded lightweight aluminum tube turns up in a variety of building and also architectural applications. Gates as well as fencing messages, handrails, and assistance columns are fine examples. It’s additionally utilized in trailers and also other transport applications where weight is a problem and also even turns up in electrical bus conductors.

Products for Light Weight Aluminum Tube and Pipe

A lot of lightweight aluminum tube, as well as pipe, is extruded from either 6061 or 6063 grade. That’s due to the fact that these tend not to work hard so the extrusion devices can run quicker. 6061 is stronger but 6063 usually looks much better thanks to a finer grain framework, and it anodizes well when a colored surface is needed.

Similar, but Different

Pipe and tube might be two words for hollow cylinders, but as we’ve explained, they’re not the same. Basically, the pipe uses the inside and the tube the outside.