Aluminum tubes come in a variety of shapes, each designed for specific purposes and applications. Round and square aluminum tubes are the most common profiles, but how do you know which one to choose? The shape you select impacts factors like strength, load distribution, and aesthetic appeal, so it’s important to understand these nuances before making your decision. In this article, we’ll explore the characteristics of both aluminum round and square tubes, compare their strengths, and guide you in selecting the most suitable option for your needs.

Know the Properties and Characteristics

Before diving into application-specific performance, it’s important to examine the inherent properties and characteristics of round and square aluminum tubes. These properties help determine how each tube behaves under various conditions and the environments they’re best suited for.

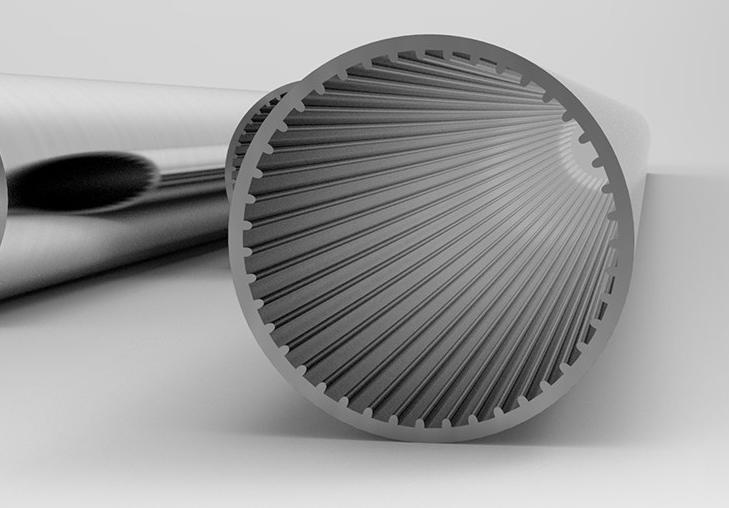

Key Properties of Round Aluminum Tubes

Round tubes have a uniform, circular cross-section, providing some distinct advantages:

- Weight Distribution: Due to their circular design, round tubes evenly distribute stress and weight. This makes them highly efficient in applications where forces are applied in all directions, such as in pipelines, railings, and frames.

- Flexibility: The curved shape allows round tubes to be more flexible under pressure. They bend more easily without compromising structural integrity, making them ideal for applications requiring curvatures or stress distribution.

- Aerodynamics: The smooth, round profile reduces drag and wind resistance, which is why they are commonly used in vehicles and aerodynamic designs.

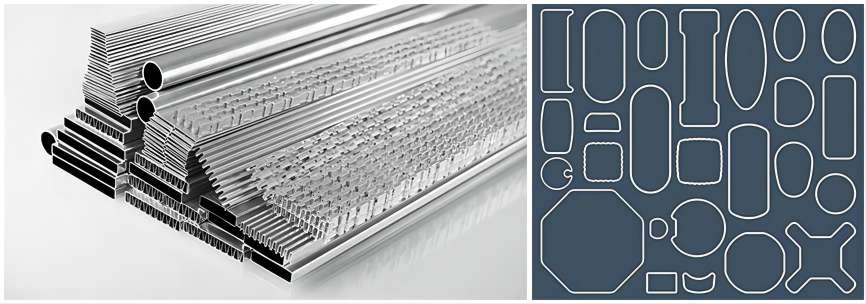

Key Properties of Square Aluminum Tubes

Square tubes feature a uniform, right-angled design and offer different advantages:

- Structural Rigidity: Square tubes have flat sides that provide more contact surface area, making them highly rigid and capable of bearing more weight compared to round tubes. This makes them ideal for load-bearing applications.

- Ease of Fabrication: The flat surfaces of square tubes make them easier to weld, drill, or attach to other flat materials. This increases their versatility in construction and fabrication tasks.

- Visual Appeal: Square tubes offer a more modern, sleek look, making them popular in architectural and design projects.

Comparison of Strength and Durability

When it comes to strength and durability, the choice between round and square tubes largely depends on the type of forces they will endure. Round tubes are generally better at handling torsional or twisting forces, as the circular shape distributes stress more evenly across the surface. On the other hand, square tubes excel in bearing compressive forces because of their rigid, flat sides, which provide stronger support in vertical and horizontal applications.

- Round Tube Strength: Performs well under multi-directional forces, making it suitable for dynamic environments.

- Square Tube Strength: Offers greater rigidity and strength when used in structural frameworks, where compression and bending forces are involved.

Performance in Different Applications

Aluminum tubes are used across a wide range of industries, and each shape has its advantages depending on the application. Understanding how round and square tubes perform in different scenarios will help you determine which is right for your project.

Round Aluminum Tube Applications

- Fluid and Gas Transport: The round profile allows for smoother flow of liquids and gases, reducing friction and pressure drops. Round tubes are ideal for pipelines, water systems, and gas transportation lines.

- Automotive and Aerospace: Due to their aerodynamic properties, round tubes are commonly used in vehicle chassis, bicycle frames, and aerospace components, where reducing drag and maintaining high strength is critical.

- Railing and Guardrails: Round tubes are preferred in railings and guardrails because their shape provides a comfortable grip and reduces the risk of injury from sharp edges.

Square Aluminum Tube Applications

- Construction and Building Frameworks: Square tubes are frequently used in structural applications like building frames, scaffolding, and load-bearing columns due to their superior rigidity and strength.

- Furniture and Design: In furniture making and interior design, square tubes provide a modern and clean look. Their flat surfaces make them easier to join with other materials, and they offer a stable base for tables, chairs, and shelving units.

- Signage and Support Structures: Square tubes’ ability to resist compression and bending makes them ideal for support structures like signage posts, display stands, and machine frameworks.

Choosing the Right Aluminum Tube for Your Project

Selecting the right aluminum tube depends on your specific project needs. By considering factors such as load requirements, design aesthetics, and the nature of the application, you can make an informed choice between round and square tubes.

| Factor | When to Choose Round Aluminum Tube | When to Choose Square Aluminum Tube |

| Load Type and Direction | Choose for projects requiring multi-directional force distribution, such as twisting or bending. | Choose for projects needing strong support under static or compressive loads. |

| Strength | Ideal for applications needing high torsional strength and even stress distribution. | Ideal for applications requiring rigidity and higher load-bearing capacity. |

| Aesthetics and Design | Opt for round tubes if your design prioritizes smooth curves or aerodynamics. | Opt for square tubes if a modern, clean, and structured appearance is important. |

| Ease of Fabrication | Choose round tubes if complex joining techniques are manageable and curvature is needed. | Choose square tubes if you need easy welding, joining, or integration with flat surfaces. |

| Applications | Best for fluid/gas transport, automotive, aerospace, and railings where shape flexibility is key. | Best for building frameworks, furniture, signage, and support structures where stability is critical. |

| Budget | Choose round tubes for cost-sensitive projects, especially where simplicity in production is valued. | Choose square tubes if additional rigidity can reduce overall material usage, despite slightly higher cost. |

| Suitability for Dynamic Loads | Ideal for projects with dynamic loads, such as moving or vibrating components. | Ideal for static, load-bearing structures that require long-term strength and stability. |

Choosing between aluminum round and square tubes comes down to understanding your project’s specific needs. For fluid dynamics and aerodynamics, round tubes are an excellent choice. If your project requires strong structural support and ease of fabrication, square tubes are likely the better option. Consider the load, design, and fabrication requirements before making your final decision. CHAL is a wholeasle aluminum tube manufacturer in china who can provide you both round and square aluminum tube, any customized needs can also accepted. Please feel free to contact us for your specific needs.