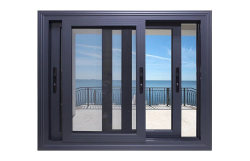

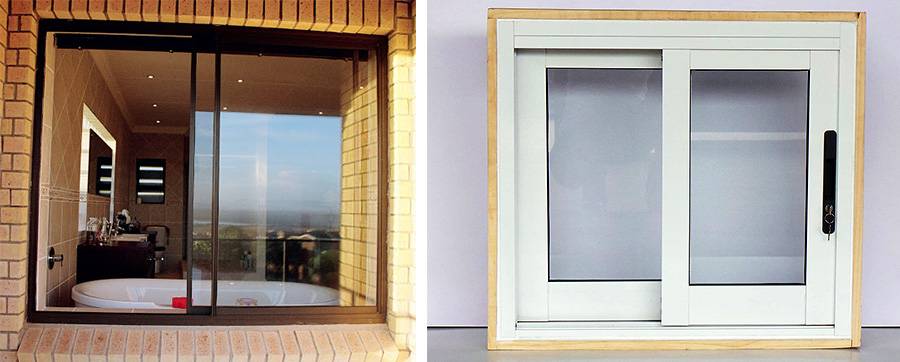

Aluminum sliding windows have become a staple in modern construction due to their aesthetic appeal, durability, and cost-effectiveness. Their popularity stems from a combination of factors, including their space-saving design, ease of operation, and ability to blend seamlessly with various architectural styles. This article provides an in-depth exploration of the performance characteristics of aluminum sliding windows, as well as common problems that may arise and their corresponding solutions.

Performance Characteristics of Aluminum Sliding Windows

1. Sound Insulation

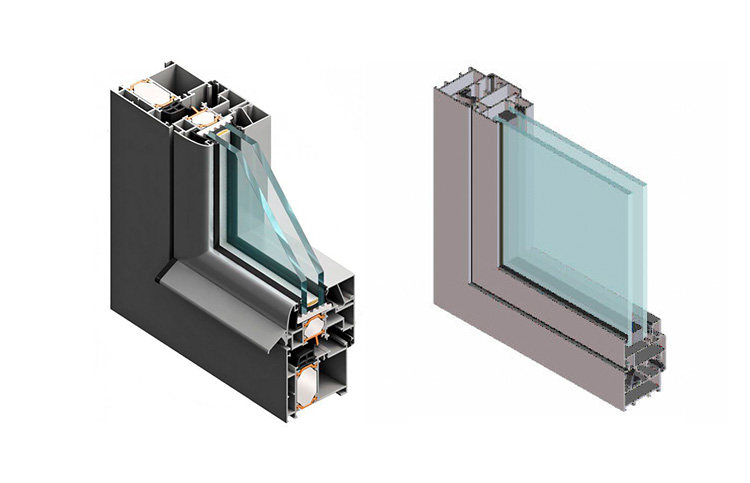

One of the standout features of aluminum sliding windows is their excellent sound insulation properties. These windows are designed to minimize noise pollution, making them ideal for urban environments or areas near busy streets. The use of double or triple glazing, combined with high-quality sealing strips, significantly reduces the transmission of external noise. For instance, in high-rise apartments located in noisy city centers, aluminum sliding windows can create a peaceful indoor environment by blocking out traffic and construction sounds.

2. Thermal Insulation

Aluminum sliding windows are also known for their superior thermal insulation capabilities. Thanks to their low thermal conductivity and the incorporation of thermal break technology, these windows effectively prevent heat transfer. In winter, they help retain indoor warmth, while in summer, they keep the heat out, reducing the need for excessive heating or cooling. Compared to traditional wooden or steel windows, aluminum sliding windows offer better energy efficiency, contributing to lower utility bills and a reduced carbon footprint.

3. Waterproofing

The waterproofing performance of aluminum sliding windows is another key advantage. These windows are designed with features such as drainage holes and high-quality sealing strips to prevent water infiltration. In regions with heavy rainfall or high humidity, aluminum sliding windows provide reliable protection against leaks and moisture damage. For example, in coastal areas, where saltwater exposure can accelerate corrosion, the anti-corrosion properties of aluminum alloy ensure long-lasting performance.

4. Wind Resistance

Aluminum sliding windows are engineered to withstand strong winds, making them suitable for areas prone to storms or hurricanes. The robust frame structure and reinforced design enable these windows to resist high wind pressure without deformation or damage. In coastal or mountainous regions, where strong winds are common, aluminum sliding windows offer both safety and durability.

5. Durability and Lifespan

The durability of aluminum sliding windows is one of their most appealing attributes. Aluminum is inherently resistant to corrosion, rust, and wear, ensuring that the windows maintain their appearance and functionality over time. Advanced surface treatments, such as powder coating or anodizing, further enhance their resistance to environmental factors. With proper maintenance, aluminum sliding windows can last for decades, making them a cost-effective investment for homeowners and builders.

Common Issues and Solutions

1. Difficulty Sliding: This is perhaps the most frequent complaint with sliding windows. It can manifest as sticking, jerking, or complete immobility.

Causes:

- Debris Accumulation: Dust, dirt, leaves, and other debris can accumulate in the window tracks, obstructing the smooth movement of the rollers.

- Damaged Rollers: The rollers, which bear the weight of the window sash, can wear down, become flattened, or break over time. This is especially true for lower-quality rollers.

- Misaligned Tracks: The tracks themselves can become bent, warped, or misaligned due to impact, settling of the building, or improper installation.

- Lack of Lubrication: Rollers and tracks may require occasional lubrication to minimize friction.

- Paint Buildup: If the window has been painted, excess paint can sometimes create a sticky surface between the sash and the frame.

Solutions:

- Regular Cleaning: Use a brush, vacuum cleaner with a crevice tool, or damp cloth to regularly clean the tracks. Pay particular attention to removing debris from the grooves where the rollers run.

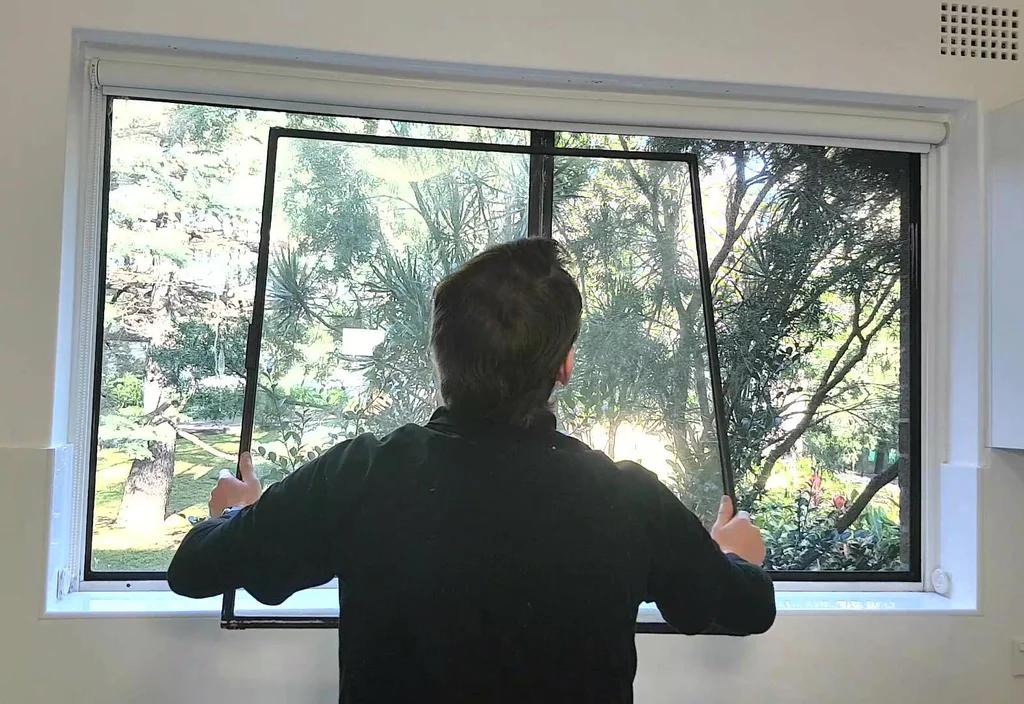

- Roller Replacement: Replacing worn or damaged rollers is crucial. It’s often a simple DIY task. Ensure you purchase compatible rollers that match the existing ones in size and type. Consider upgrading to higher-quality rollers for smoother operation and increased longevity.

- Track Realignment: Minor misalignments can sometimes be corrected by carefully adjusting the tracks. However, more serious misalignments may require professional help.

- Lubrication: Apply a silicone-based lubricant to the tracks and rollers. Avoid using oil-based lubricants, as they can attract dirt and grime.

- Paint Removal: Carefully scrape or sand away any excess paint that is interfering with the window’s movement.

2. Poor Sealing: A poorly sealed window can lead to drafts, water leaks, and increased energy costs.

Causes:

- Deteriorated Weather Stripping: The flexible weather stripping around the window frame can become brittle, cracked, or compressed over time, losing its ability to create an airtight seal.

- Improper Installation: Gaps between the window frame and the wall can occur if the window is not installed correctly.

- Gaps in the Frame: In some cases, the window frame itself might have manufacturing defects or gaps.

Solutions:

- Weather Stripping Replacement: Replacing worn weather stripping is a relatively inexpensive and effective way to improve sealing. Choose weather stripping that is compatible with your window type.

- Caulking: Apply a high-quality sealant (caulk) around the perimeter of the window frame where it meets the wall. This will fill any gaps and prevent air and water infiltration. Ensure the surface is clean and dry before applying caulk.

- Frame Inspection and Repair: Inspect the window frame for any gaps or damage. Small gaps can be filled with caulk, while larger gaps or damage may require professional repair.

3. Leaks: Leaking windows can cause significant damage to walls, floors, and furniture.

Causes:

- Clogged Drainage Holes: Small drainage holes in the window frame are designed to allow water to escape. These holes can become clogged with debris.

- Damaged Seals: The seals between the glass and the frame, or between the frame and the wall, can fail, allowing water to enter.

- Structural Issues: In some cases, leaks can be caused by structural problems with the window itself, such as cracks or warping.

Solutions:

- Drainage Hole Cleaning: Use a small wire or toothpick to clear any obstructions from the drainage holes.

- Seal Replacement/Repair: Replace or repair any damaged seals. This may involve re-caulking around the window or replacing the glazing seals.

- Professional Inspection: If you suspect a structural issue, it’s best to consult a professional window installer or contractor.

4. Hardware Issues: Problems with locks, handles, and other hardware can compromise the security and functionality of the window.

Causes:

- Wear and Tear: Locks, handles, and other moving parts can wear down over time due to repeated use.

- Corrosion: Exposure to the elements can cause corrosion of metal hardware.

- Damage: Hardware can be damaged by impact or misuse.

Solutions:

- Hardware Replacement: Replace worn or damaged hardware with compatible parts. Many hardware stores carry replacement parts for common window brands.

- Lubrication: Lubricate moving parts with a silicone-based lubricant to ensure smooth operation.

- Regular Maintenance: Inspect hardware regularly for signs of wear or damage and address issues promptly.

5. Glass Breakage: While less common than other issues, broken glass is a serious problem that requires immediate attention.

Causes:

- Accidental Impact: Flying objects, vandalism, or even accidental contact can break window glass.

- Thermal Stress: Extreme temperature fluctuations can sometimes cause the glass to crack.

- Faulty Installation: Improper installation can put stress on the glass, making it more susceptible to breakage.

Solutions:

- Professional Replacement: Replacing broken window glass is best left to a qualified glazier. They have the expertise and tools to safely remove the broken glass and install a new pane. Ensure the replacement glass matches the original in type, thickness, and any special coatings (e.g., low-E).

By understanding these common problems and their solutions, homeowners can effectively maintain their aluminum alloy sliding windows and ensure their long-lasting performance. Regular maintenance and prompt attention to minor issues can prevent them from escalating into more costly repairs.

Aluminum sliding windows offer a compelling combination of performance, aesthetics, and value. By understanding their characteristics, common issues, and how to address them, you can make informed decisions when selecting and maintaining these windows, ensuring years of trouble-free performance and enjoyment. For all your architectural aluminum needs, CHAL can offer a wide range of solutions. Contact us today for a personalized consultation—we’ll respond within 24 hours.