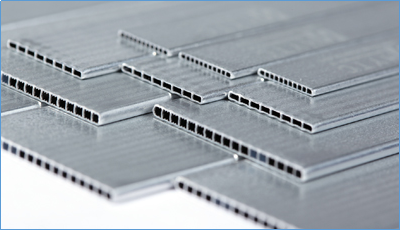

In modern buildings, you’ll often notice aluminum strip gusset ceilings when you look up. These are a common type of metal ceiling known as aluminum strip ceilings. A newer type of ceiling material called aluminum strip buckle ceilings is also becoming more widespread, with applications in shopping malls, office buildings, government buildings, kitchens, toilets, and other locations.

One advantage of aluminum strip buckle ceilings is that they are entirely made of metal, which makes them very durable and long-lasting. They have smooth lines, come in a variety of colors, and have an attractive appearance. Additionally, they are fireproof, moisture-proof, easy to install, and easy to clean.

Overall, aluminum strip buckle ceilings have become an essential component of modern building design and are now widely used throughout the country. The industry that produces these ceilings has become fully established in large and medium-sized cities across the nation and is now mature and comprehensive.

3 Surface Treatment for Aluminum Strip Gussets

At present, the surface treatment mainly includes coating, rolling, and spraying.

- Roll-coated aluminum strip gusset ceiling

The roll-coated aluminum strip buckle ceiling is composed of three layers: a top coat, a primer, and a back coat. The back coat serves as an anti-oxidant to increase the ceiling’s longevity.

The production process for these ceilings involves several steps, including forming the aluminum strips on a machine, unloading and inspecting the finished product, and packaging and storing it.

The surface of the roll-coated aluminum strip buckle ceiling is smooth and uniform, and it typically does not have any major defects such as missed coating, shrinkage cavities, scratches, or shedding. However, there may be minor defects such as bubbles, pits, or inclusions, which is a normal occurrence.

- Aluminum strip gusset film-coated ceiling

The surface treatment and production process for film-coated aluminum strip buckle ceilings are the same as for roll-coated boards, but with one key difference: the surface layer of the film-coated board is made of PVC film.

The PVC film on the surface of film-coated aluminum strip buckle ceilings is securely attached, and there are typically no major defects such as wrinkles, scratches, peeling, or missing stickers. However, it is normal for the surface to have a small number of micro-wrinkles, unevenness, and other defects on both sides within a width direction of 0.2mm.

- Spraying aluminum strip gusset ceiling

The production process for better-sprayed boards involves several steps, including preparing semi-finished products, degreasing, cleaning, chromizing, drying (using a cold drying process), electrostatic application, solidification and cooling, unloading and inspection, and packaging and storage.

The better-sprayed boards available on the market typically have a surface that uses epoxy resin electrostatic for adhesion. This surface has a level 1 adhesion and an 18-degree gloss. It also has no color differences, bubbles, particles, and is weather-resistant.

The development prospect of aluminum strip gusset ceiling

Aluminum strip buckle ceilings are widely popular due to their smooth lines, rich colors, good appearance, fire prevention, moisture resistance, easy installation, and easy cleaning. Designers and customers can choose aluminum strip buckle ceilings that match the colors of furniture and floors, making them a popular choice for consumers.

Over time, various types of aluminum strip buckle ceilings have been developed, including gypsum board, mineral wool board, and PVC aluminum strip buckle. The aluminum strip buckle plate originally only had a spraying board, but it has since been developed into roll coating and lamination (with lamination mostly used for home decoration).

Currently, the film used in the market is PVC film, but PET film produced in Japan is becoming more environmentally friendly. Considering these advancements, the prospects for aluminum strip buckle ceilings in the next few years are very promising.

Related Products

Related Articles