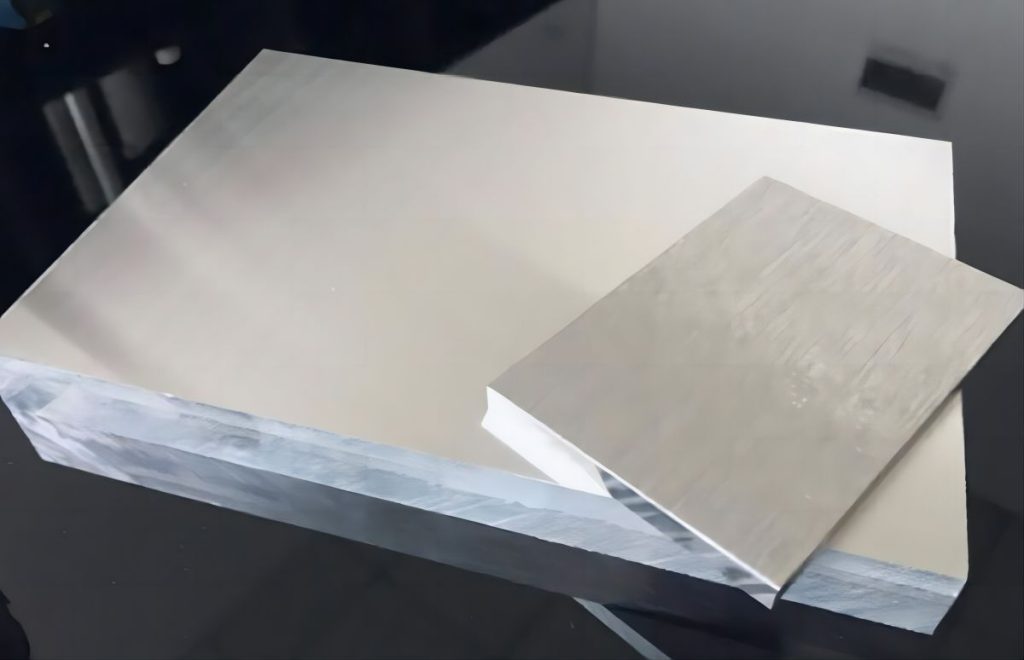

Aluminum is a versatile material that finds extensive use in various industries due to its excellent properties such as lightweight, corrosion resistance, and machinability. When it comes to specific applications, the choice of the right aluminum alloy can significantly impact the performance and cost-effectiveness of a project. In this article, we will compare two popular aluminum alloys: Aluminum tooling plate and 6061 aluminum plate, exploring their properties and applications in different industries.

Properties of Aluminum Tooling Plate VS 6061 Aluminum Plate

Properties of Aluminum Tooling Plate

The aluminum tooling plate, also known as ATP-5, is a high-quality precision machined plate specifically designed for tooling and mold-making applications. This alloy possesses several unique properties that make it ideal for these purposes.

- Dimensional Stability: One of the key advantages of aluminum tooling plates is its high dimensional stability. This property allows it to maintain its shape and flatness even under heavy machining or stress, making it perfect for precision machining operations. Manufacturers can rely on this stability to achieve tight tolerances and accurate results, crucial for producing high-quality molds.

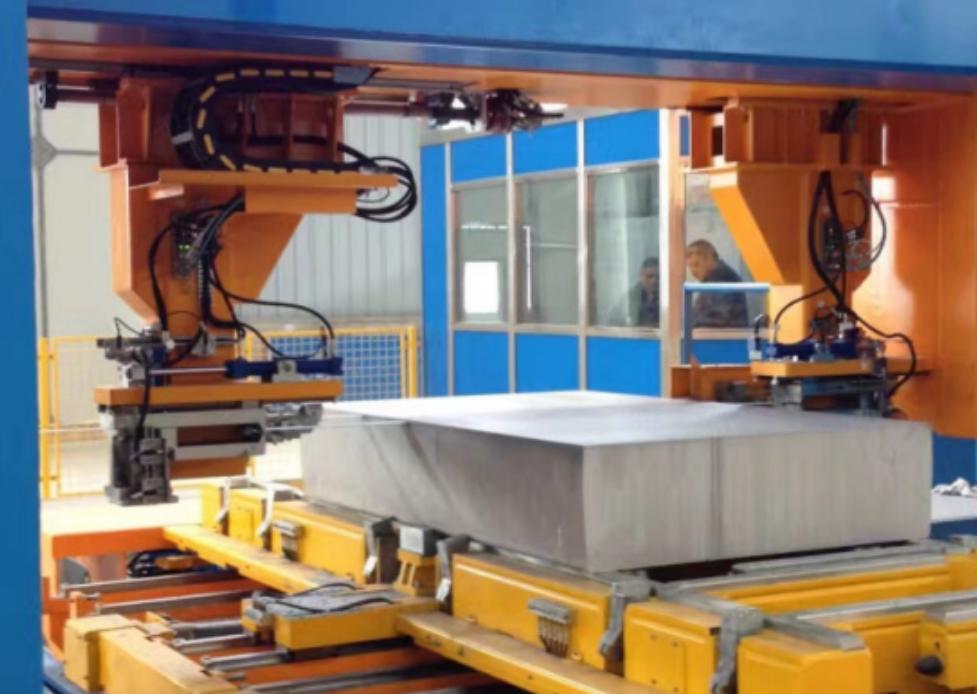

- Low Internal Stress: During the manufacturing process, Aluminum tooling plate undergoes stress-relieving heat treatment. This treatment reduces internal stresses in the material, which helps prevent distortion or warping during machining or prolonged use. Low internal stress ensures the tooling plate retains its shape and accuracy, leading to consistent and reliable performance.

- Machinability: Aluminum tooling plate exhibits excellent machinability. The uniform microstructure and low internal stress enable easy and precise machining, eliminating the need for additional surface treatments. This property streamlines the production process and reduces costs, making it a preferred choice for tooling applications.

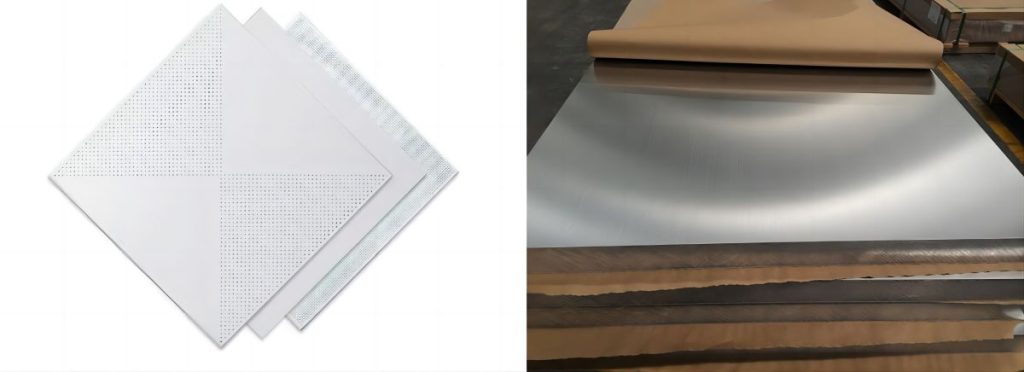

- Thickness Tolerance and Surface Finish: Aluminum tooling plate is available in various thicknesses with tight tolerances, ensuring consistent and predictable material thickness. This feature is essential when dimensional accuracy is crucial in tooling and mold-making. Additionally, the tooling plate has a smooth surface finish, facilitating mold release and enhancing the quality of molded products.

Properties of 6061 Aluminum Plate

6061 aluminum plate is a versatile alloy known for its excellent strength, formability, and corrosion resistance. Its properties make it a preferred choice in a wide range of applications.

- High Strength: One of the primary advantages of 6061 aluminum plate is its high strength. It is widely used in structural applications where load-bearing capabilities are essential. This alloy’s strength-to-weight ratio makes it suitable for various structural components in buildings, bridges, and other infrastructure projects.

- Formability: 6061 aluminum plate exhibits high formability, making it suitable for shaping processes like rolling, bending, or extrusion. Manufacturers can easily create complex shapes and designs, making it ideal for applications requiring curved or irregular forms.

- Weldability: Another significant advantage of 6061 aluminum plate is its excellent weldability. It can be readily welded using conventional and advanced welding techniques, allowing for easy assembly and fabrication of components or structures.

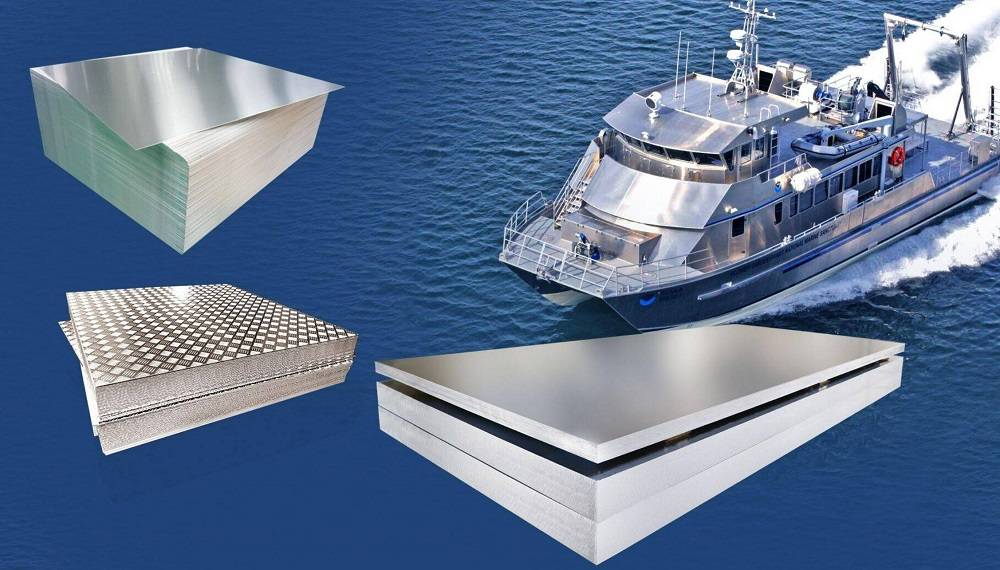

- Corrosion Resistance: 6061 aluminum plate has good resistance to atmospheric and marine corrosion. It forms a protective oxide layer that helps protect the metal from corrosion, making it suitable for outdoor and marine applications.

Aluminum tooling plate excels in dimensional stability, low internal stress, and machinability, making it ideal for mold-making, tooling, and precision machining. On the other hand, 6061 aluminum plate stands out for its high strength, formability, weldability, and corrosion resistance, making it a preferred choice for structural components, automotive parts, marine equipment, and aerospace applications.

Applications of Aluminum Tooling Plate VS 6061 Aluminum Plate

Applications of Aluminum Tooling Plate

- Mold-Making and Tooling: Aluminum tooling plate is widely used in the manufacturing of molds and tooling for various industries. Its dimensional stability and low internal stress make it an excellent choice for creating precision molds for plastic injection molding, blow molding, and thermoforming processes.

- Injection Molding and Blow Molding: The tooling plate is commonly used as a mold base for injection molding and blow molding applications. It provides a stable and reliable platform for producing plastic parts with intricate shapes and details.

- Thermoforming: Aluminum tooling plate is employed in thermoforming processes to create packaging trays, containers, and other items from thin sheets of plastic.

- Prototype Development: Due to its machinability and ability to hold tight tolerances, Aluminum tooling plate is often used in rapid prototyping and development of new products. Manufacturers can quickly create prototypes to test designs before proceeding to full-scale production.

- Fixtures and Jigs: In manufacturing processes, an aluminum tooling plate is used to fabricate fixtures and jigs, aiding in the accurate positioning and alignment of components during production.

- Aerospace Tooling: The aerospace industry extensively utilizes aluminum tooling plates for manufacturing various tooling and fixtures required for aircraft assembly and maintenance.

Applications of 6061 Aluminum Plate

- Structural Components: The high strength and formability of 6061 aluminum plate make it a popular choice for structural components in buildings, bridges, and other infrastructure projects.

- Automotive Parts: In the automotive industry, 6061 aluminum plate is widely used for manufacturing components such as chassis, body panels, wheels, and suspension parts.

- Marine Equipment: The corrosion resistance of 6061 aluminum plate makes it suitable for marine applications, including boat hulls, decks, and other marine structures.

- Aerospace Components: The aerospace industry extensively uses 6061 aluminum plates for aircraft components that require a balance of strength and weight, such as wing spars, fuselage frames, and bulkheads.

- Bicycle Frames: 6061 aluminum plate is commonly used to build lightweight and durable bicycle frames for various types of bikes.

- Heat Sinks: Due to its good thermal conductivity, the 6061 aluminum plate is used in heat sink applications for electronic devices to dissipate heat efficiently.

- Packaging: 6061 aluminum plate is employed in the manufacturing of cans, containers, and packaging materials.

- Machinery Components: The combination of strength and formability makes the 6061 aluminum plate suitable for fabricating various machinery components.

The applications of each alloy are tailored to their specific properties. Aluminum tooling plate is predominantly used in the creation of molds and tooling for injection molding, blow molding, and thermoforming processes. It finds applications in industries such as automotive, aerospace, and consumer goods. 6061 aluminum plate, with its strength and formability, is widely employed in structural and load-bearing components across various industries, including construction, automotive, marine, and electronics.

Conclusion

Aluminum tooling plates and 6061 aluminum plates are two popular aluminum alloys, each with distinct properties and applications. While aluminum tooling plate excels in precision mold-making and machining, 6061 aluminum plate is sought after for its strength, formability, and corrosion resistance in structural and load-bearing applications. Understanding the unique properties of each alloy is crucial in choosing the right material for specific projects, ensuring optimal performance and cost-effectiveness in various industries.