Aluminum tube coils, known for their flexibility and efficiency as conductive materials, play a pivotal role in various electromagnetic devices. These versatile components have found their way into everyday appliances, industrial equipment, and advanced technologies. From induction cookers and transformers to wireless chargers and MRI machines, aluminum tube coils exemplify the marriage of practicality and scientific innovation. This article delves into their broad applications and the scientific principles that underpin their functionality.

Applications of Aluminum Tube Coils

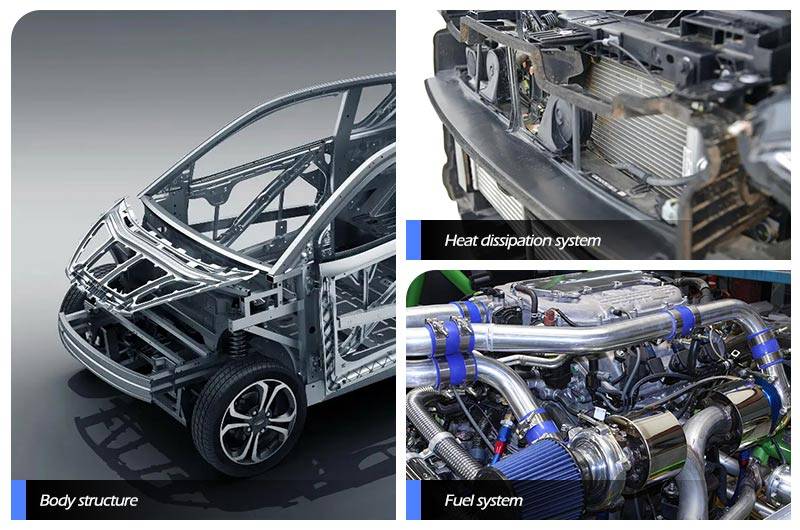

Aluminum tube coils find applications in a wide range of industries, including:

1. Electromagnetic Induction Heating Devices

One of the most prominent applications of aluminum tube coils is in electromagnetic induction heating. Devices such as induction cookers and industrial heaters leverage these coils to produce high-efficiency heat through electromagnetic fields.

The principle is straightforward: when an alternating current flows through the aluminum tube coil, it generates a rapidly changing magnetic field. This field induces eddy currents in a nearby conductive object, causing it to heat up due to electrical resistance.

The advantages of this technology are manifold. First, it provides energy-efficient and uniform heating, essential for precision processes in industries like metal forging, plastic molding, and food processing. Second, it is environmentally friendly, reducing the reliance on fossil fuels for heat generation. As demand for sustainable industrial practices rises, aluminum tube coils will likely become even more integral to electromagnetic heating solutions.

2. Wireless Charging Systems

Wireless charging is a modern marvel that has revolutionized how we power devices. At the heart of this technology are aluminum tube coils. These coils act as the inductive components that facilitate the transfer of electrical energy from a charging base to a device without physical contact.

The mechanism involves the creation of an alternating magnetic field by the primary coil in the charging base. This field induces an electric current in the secondary coil embedded in the device, charging its battery.

The lightweight and cost-effective nature of aluminum make it an excellent choice for these applications, especially in portable electronic devices and electric vehicles (EVs). As wireless charging technology advances, aluminum tube coils will continue to play a critical role in making it more efficient and accessible.

3. Transformers

Traditionally, copper wires have been the standard material for transformers due to their excellent conductivity. However, aluminum tube coils offer a compelling alternative in scenarios where weight reduction is a priority.

In transformers, aluminum tube coils serve as primary or secondary windings. They rely on mutual inductance to transfer electrical energy between circuits. Although aluminum has slightly lower conductivity than copper, it is significantly lighter and more cost-effective, making it suitable for transformers used in applications like renewable energy systems and portable electrical devices.

4. Inductors in Circuit Design

In electronic circuits, inductors are crucial for managing current and voltage. Aluminum tube coils, with their unique self-inductive properties, fulfill various roles, such as filtering, tuning, and energy storage.

For example, in power supply circuits, these coils help smooth out fluctuations, ensuring a steady output. In communication systems, they aid in tuning frequencies for better signal clarity. Their reliability and efficiency make aluminum tube coils indispensable in electronic system design.

5. Electromagnetic Welding Equipment

High-precision industries like micro-motor manufacturing rely on aluminum tube coils for electromagnetic welding. This process uses high-frequency magnetic fields to generate localized heat, enabling precise and efficient joining of metal components.

The aluminum tube coil’s role is to create the alternating magnetic field necessary for inducing eddy currents in the metal surfaces to be welded. This method is not only energy-efficient but also allows for high levels of control, making it ideal for applications requiring accuracy and durability.

6. Sensors

Aluminum tube coils are also integral to the design of magnetic induction sensors. These sensors detect changes in magnetic fields and convert them into electrical signals for data collection and analysis.

Applications range from environmental monitoring and automotive systems to industrial automation. The lightweight and corrosion-resistant properties of aluminum ensure that these sensors can operate reliably in diverse environments.

7. MRI Devices

In the medical field, aluminum tube coils contribute to the development of magnetic resonance imaging (MRI) technology. They are used in constructing parallel transmission coils, which work together to generate high-quality images of human tissues.

The coils create alternating magnetic fields that interact with the body’s hydrogen atoms. By analyzing the signals emitted, MRI machines produce detailed images for diagnostic purposes. Aluminum’s properties make these coils lightweight, enhancing the ease of handling and installation while maintaining the precision needed in medical diagnostics.

Scientific Principles Behide Applications

Electromagnetic induction, a fundamental principle in physics, is the phenomenon where an electromotive force (EMF) is induced in a conductor when it is exposed to a changing magnetic field. This principle forms the foundation for the operation of aluminum tube coils.

Faraday’s Law of Induction

Faraday’s law states that the magnitude of the induced EMF is directly proportional to the rate of change of magnetic flux through the conductor. Mathematically, this can be expressed as:

EMF = -N * (dΦ/dt)

Where:

- EMF: Electromotive force (volts)

- N: Number of turns in the coil

- dΦ/dt: Rate of change of magnetic flux (weber/second)

Lenz’s Law

Lenz’s law provides the direction of the induced current. It states that the induced current flows in such a direction as to oppose the change that produced it. This law ensures that energy conservation is maintained in electromagnetic induction processes.

For instance, in transformers and wireless chargers, the mutual induction between primary and secondary coils facilitates efficient energy transfer. The rate of magnetic flux change determines the strength of the induced EMF, which is central to the operation of all electromagnetic devices.

Eddy Current Effect

Another critical principle is the eddy current effect. When an alternating current (AC) is passed through an aluminum tube coil, it generates a time-varying magnetic field around it. This magnetic field induces eddy currents within the coil itself and in any nearby conductive material. Eddy currents are circular electric currents that flow within a conductor in response to a changing magnetic field.

The intensity of eddy currents depends on several factors, including the frequency of the AC current, the conductivity of the material, and the geometry of the conductor. In aluminum tube coils, the high electrical conductivity of aluminum facilitates the generation of strong eddy currents.

Functional Roles of Aluminum Tube Coils

- Generation of Alternating Magnetic Fields: Aluminum tube coils are pivotal in creating alternating magnetic fields, the basis for operations like induction heating, wireless charging, and welding. Their efficiency in converting electrical energy into magnetic fields ensures high performance in these applications.

- Efficient Energy Conversion: In transformers, aluminum tube coils facilitate the efficient transfer and conversion of electrical energy. Their role in mutual inductance is critical to the stability and reliability of power distribution systems.

- Thermal Management: Aluminum tube coils excel in dissipating heat, making them suitable for high-power applications. Their thermal conductivity ensures that devices remain operational under demanding conditions, prolonging their lifespan.

- Technological Innovations: From enabling wireless power transfer to improving medical imaging, aluminum tube coils are at the forefront of technological advancements. Their versatility allows engineers to push the boundaries of what electromagnetic devices can achieve.

Aluminum tube coils have established themselves as versatile and indispensable components in the field of electromagnetic induction. Their unique properties and wide range of applications have contributed to advancements in various industries, from manufacturing and healthcare to transportation and energy. As technology continues to evolve, aluminum tube coils are poised to play an even greater role in shaping the future of electromagnetic devices.