You may have heard that the terms Aluminum tube and pipe are used interchangeably, but you are probably not sure of the difference between them. Mostly, even the experts in related industries, don’t know it exactly. After all, how different a hollow cylinder can be, who really cares to check it out? Well, I must know.

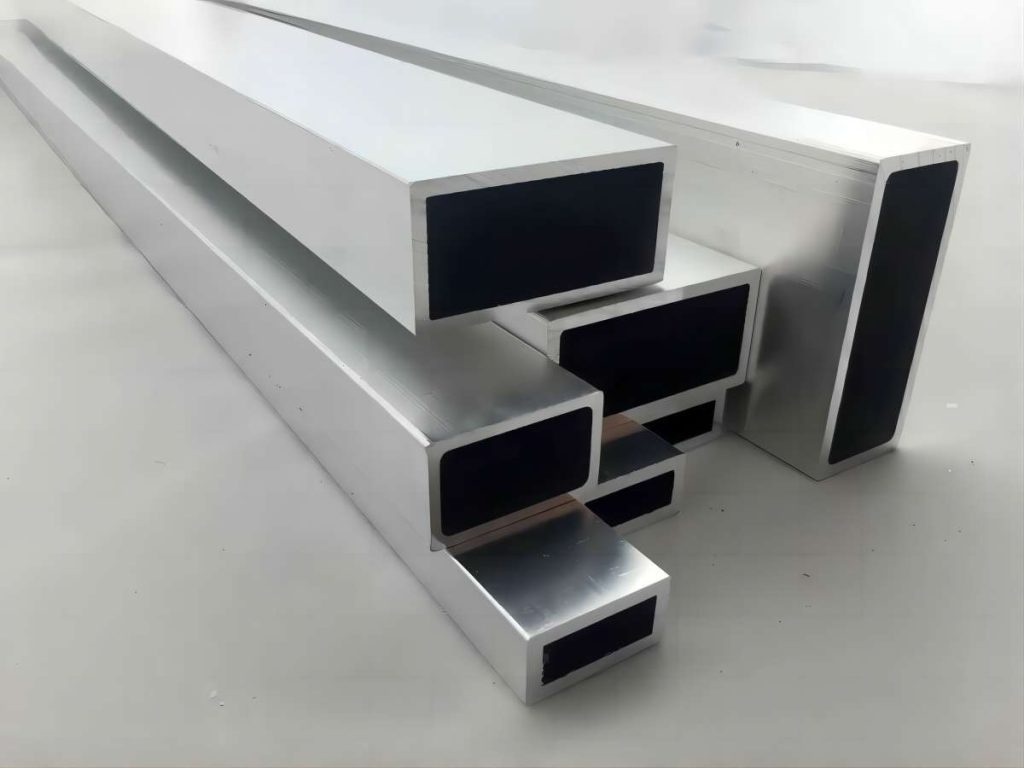

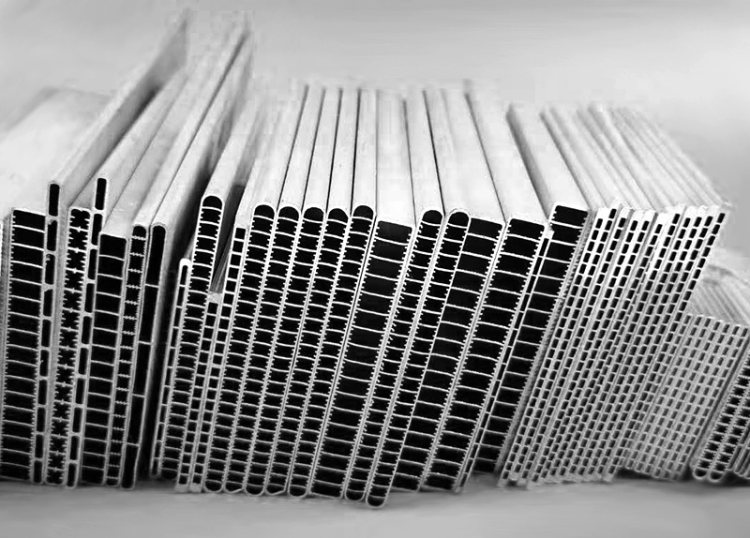

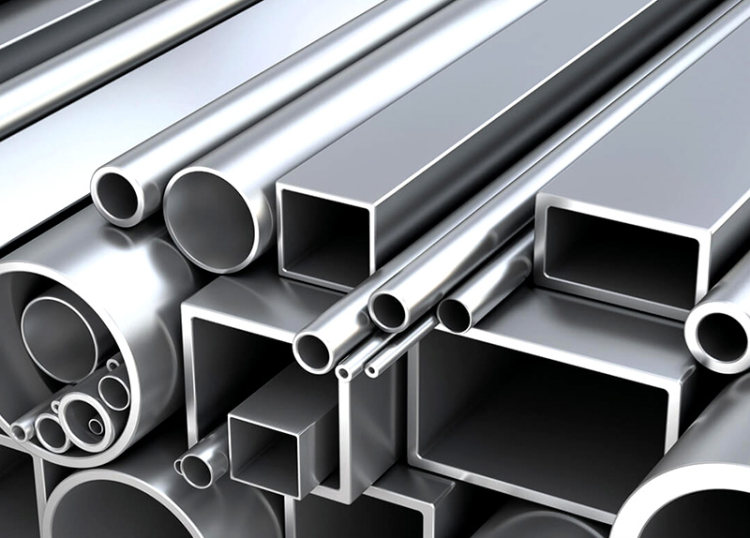

The general answer is: aluminum tubes are different from pipes in shapes, such as aluminum round tubing, aluminum rectangular tubing, aluminum square tubing, or oval hollow sections, they are measured by outer diameter (OD) and wall thickness (WT), expressed in inches or millimeters. Pipes are round pipes used to distribute fluids and gases. They are designated by the nominal pipe size (NPS or DN) and represent a rough indication of the pipeline’s transport capacity.

What is Aluminum Tubing?

Aluminum tubes are usually used in structural engineering, and the outer diameter is an important and accurate number. OD and WT (wall thickness) specify the pipe size. Aluminum pipe has many characteristics. Due to its light weight, the unit weight provided by aluminum pipe is larger than that of steel pipe. Many products benefit from lighter pipe materials’ use, especially those that require a certain degree of mobility, as outdoor furniture and wheelchairs. Aluminum tube will not lose its luster. Compared with other metals, it is easier to accept paint and other decorations, thus enhancing its beauty.

What is Aluminum Pipe?

Aluminum pipes are classified as tubular containers used in pipes and piping systems, and are usually used to transport gases and fluids. They are specified by the “Nominal Pipe Size” (NPS) and the attached table (wall thickness). NPS is a size standard established by the American National Standards Institute (ANSI) and should not be confused with various thread standards such as NPT and NPSC.

Example of difference between Aluminum Extruded Pipe and Tube

Applications for Extruded Round Pipe

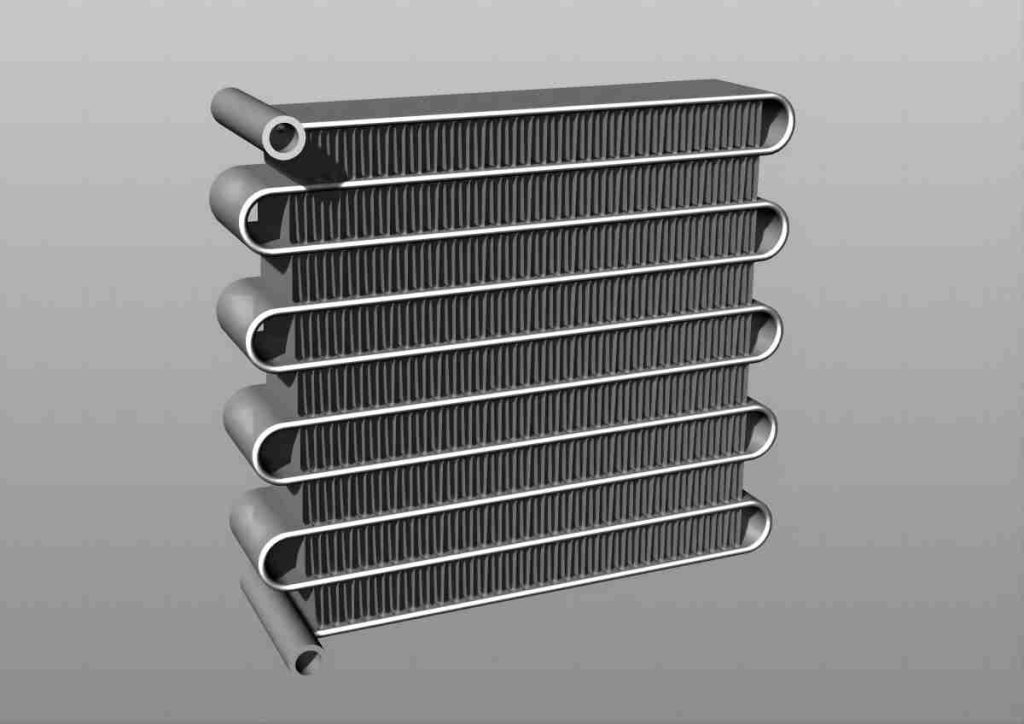

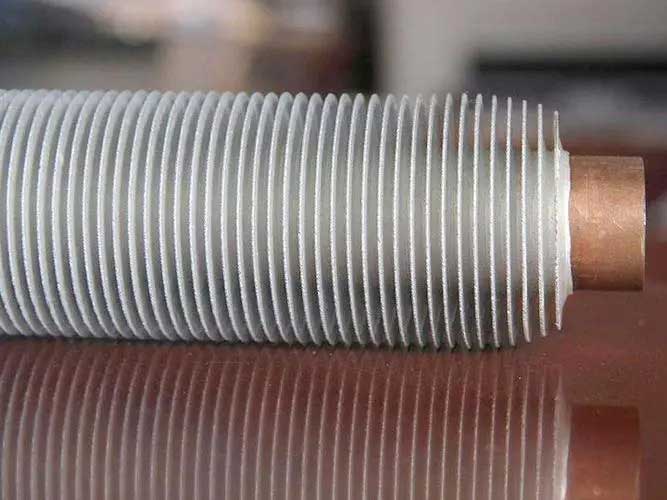

One of the most useful features of pipes is in heat exchangers. This is because aluminum has excellent thermal conductivity and is easy to weld. Because of its light weight, solar water heating systems also need it because it does not put too much weight on the roof.

Applications for Extruded Tube

Extruded aluminum tubes exist in a wide range of architectural and structural applications. Gates and fence posts, handrails and pillars are good examples. It is also used in trailers and other transportation applications where weight is considered, even in electrical bus conductors.

| PIPE vs TUBE | ALUMINUM PIPE | ALUMINUM TUBE |

| Key Dimensions (Pipe and Tube Size Chart) | The most important dimensions for an Aluminum pipe are the outer diameter (OD) and the wall thickness (WT). OD minus 2 times WT (SCHEDULE) determines the inside diameter (ID) of a pipe, which makes the liquid capacity of the pipe. | The most important dimensions for a steel tube are the outside diameter (OD) and the wall thickness (WT). These parameters are expressed in units like inches or millimeters and express the true dimensional value of the hollow section. |

| Wall Thickness | The thickness of an aluminum pipe is designated with a “Schedule” value (the most common are Sch. 40, Sch. STD., Sch. XS, Sch. XXS). Two pipes of different NPS with the same schedule have different wall thicknesses in inches or millimeters. | The thickness of an aluminum pipe is designated with a “Schedule” value (the most common are Sch. 40, Sch. STD., Sch. XS, Sch. XXS). Two pipes of different NPS and the same schedule have different wall thicknesses in inches or millimeters. |

| Types of Pipes and Tubes (Shapes) | Round only | Round, rectangular, square, oval |

Different Types of Materials for Aluminum Tube and Pipe

Most aluminum tubes are extruded from 6061 or 6063 grades. This is because they tend not to be work-hardened, so the extrusion equipment can run faster. 6061 is more durable, but 6063 generally looks better, thanks to a finer grain structure and can it be anodized well when colored finishes are required.

Aluminum Tubing’s Prominent Power in Industries

Anodized aluminum tubing has benefited various industries. Outdoor manufacturers use tubing to construct materials such as tent poles, camping chair frames, and outdoor tables. In the medical industry, aluminum tubes appear in wheelchair frames, foldable stretchers, bed frames, and crutches. Aerospace, automotive, and rail transportation manufacturers use aluminum tubes in airframes, hydraulic systems, and fuel lines. Their thermal conductivity makes them a good substitute for steel or other heavier metals in refrigerators, engines, and HVAC systems. Aluminum tubes can also be used to support electrical equipment such as chain fences, liners, and accommodating desktop displays.

Alike, but Different

Pipe and tube might be two terms for hollow cylinders, but as I’ve explained, they’re not the same. Mostly, the pipe uses the pipe inside and tube the outside. If you still got some questions you can consult with Aluminum tuber supplier CHAL, who is a professional aluminium tube supplier with decades of experience in aluminum tube manufacturing.